Page 8

www.oldschoolmodels.com

Construction Manual

the bottom spar. Now that you

know how these work, remove this

web, apply glue along the edge

touching R7, and along the bottom

of the web where it contacts the

bottom spar. Glue this in position.

Then glue R5 to W3, the spar, the

leading and trailing edges.

■ ■

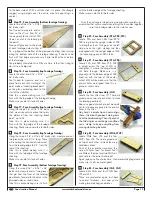

Step 33 - Wing Assembly (R5, W3)

Locate three more R5s from BP4, BP5

or BP6 and three more W3s. Working

your way inward, these webs and ribs

are glued in place, one at a time, using

the same techniques you just used on

the fi rst W3 and R5. Make sure all the

tabs, notches and slots are all correctly

positioned while the glue cures.

■ ■

Step 34 - Wing Assembly (R6, W3)

Locate two R6s from BP4 and BP5

and two more W3s. Still working

your way inward, these webs and

ribs are glued in place, one at a

time, using the same techniques

you just used on the previous ribs

and webs. Make sure all the tabs,

notches and slots are all correctly

positioned while the glue cures.

■ ■

Step 35 - Wing Assembly (SH2)

Locate four SH2s from LP7 and LP8.

Glue two of them together, one on

top of the other, to form a thicker SH2.

Make sure they are perfectly aligned

when doing this. You'll have two

matching, thicker SH2s when fi nished.

■ ■

Step 36 - Wing Assembly (SH2)

Now carefully push the two SH2s from the

previous step into the pairs of pre-cut holes

in the R6 ribs. Glue these in position to both

ribs as shown here.

■ ■

Step 37 - Wing Assembly (SH2 trim piece)

Locate one of the 1/4" x 1/4" strips of balsa

sticks - this will be your "small pieces" stick. Cut

four 2-3/8" lengths (the distance between the

ribs) off of this stick.

You'll glue one of these strips in place now,

on the back of the rear SH2 you just installed.

Make sure it is pushed fl at against the building board as well.

Set the other pieces aside as you'll use one when making the other

wing half, and the other two for the fl ap area.

Note: these are not really structural pieces - it simply completes the

back end of the servo areas, and gives your covering something to

stick to - trust us, it will make perfect sense later on in the build.

■ ■

Step 38 - Wing Assembly (R5, W3)

Locate two R5s from BP4 and BP5 and two more W3s. Still working

your way inward, these webs and ribs

are glued in place, one at a time, using

the same techniques you just used on

the previous ribs and webs. Make sure

all the tabs, notches and slots are all

correctly positioned while the glue

cures.

■ ■

Step 39 - Wing Assembly (R4, W3)

Locate one R4 from BP3 or BP4 and

another W3. Still working your way

inward, this web and rib are glued in

place, using the same techniques you

just used on the previous ribs and webs.

Make sure all the tabs, notches and slots

are all correctly positioned while the

glue cures.

■ ■

Step 40 - Wing Assembly (R3, W3)

Locate one R3 from BP3 and another

W3. Still working your way inward, this

web and rib are glued in place, using the

same techniques you just used on the

previous ribs and webs. Make sure all the

tabs, notches and slots are all correctly

positioned while the glue cures.

■ ■

Step 41 - Wing Assembly (SH2)

Locate four SH2s from LP7 and LP8. Glue

two of them together, one on top of the

other, to form a thicker SH2. Make sure they

are perfectly aligned when doing this. You'll

have two matching, thicker SH2s when

fi nished.

Now carefully push the two SH2s into the

pairs of pre-cut holes in the R3 and R4 ribs. Glue these in position to

both ribs as shown here.

■ ■

Step 42 - Wing Assembly (SH2 trim piece)

Locate one of the 2-3/8" lengths of 1/4" x 1/4" strips of balsa you

cut a few steps back.

Glue this strip in place on the back of the rear SH2 you just installed.

Make sure it is pushed fl at against the building board as well.

■ ■

Step 43 - Wing Assembly (R2, W2)

Locate R2 from BP3 and two W2s from

LP5 and LP7. Although thicker, the W2

webs are is glued in place just the same

as the other webs. The only change is

that one is glued on each side of the

lower spar. There are additional slots

in R2 and R3 to accommodate the

extra W2. Then R2 is glued in place, just like the other ribs.

■ ■

Step 44 - Wing Assembly (R1P, W1P)

Locate one R1P from LP7 and both W1Ps from LP5. You might also

want to pop out the 3° dihedral gauges (LP4 & LP5) and it's foot

that's part of LP4 as it can be used to help hold R1P at the correct

angle.

Note the face etched into both W1Ps - there's a winking eye. This