Construction Manual

www.oldschoolmodels.com

Page 15

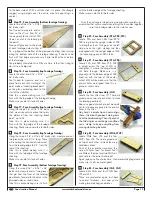

First, glue in all of the pieces from F3,

rearwards. They're all fl at which makes

holding the port side in place as easy

as clamping the two sides together

around the cabin area.

Also, place the fuselage upright on the

table, as pictured. Push down on both

sides to make sure they're fl at against

the board. We're trying to eliminate any

twists while the glue is curing. You can

check this by pulling the balsa sides

together at the rear - they should

match up, aligning with each other.

Second, work from F3 forward, using

epoxy and clamps to make this work.

Note, that if you are going to use

electric power, you'll also need to

glue in the EF1/EF2 assembly during

this same time. Note it's etched

circle that should be on the

starboard side.

As just stated, use epoxy for

this, and clamps. Epoxy for the

strength, and clamps to make

sure it all stays as you left it.

■

Step 100 - Fuse Assembly (rear fuselage pins)

This next step doesn't require any glue - you're simply holding

things in place to help in the next few steps.

Grab the vertical fi n and a few pins. You'll now put the vertical in

between the fuselage sides, then squeeze the two sides together

so they are aligned and are touching the fi n.

Now push in a few pins at various

angles to hold this all together.

What we're looking for are two

matching tapers on the fuselage

sides, if you were to sight down the

fuselage from the front and back.

Also the sides should be level with

each other.

■

Step 101 - Fuse Assembly (F5)

Locate the F5 assembly from several

steps back.

You'll now glue this in between

the fuselage sides, making sure

it's tabs are fully inserted to the

corresponding slots pre-cut into

both sides of the fuselage.

■

Step 102 - Fuse Assembly (F6)

Locate F6 from BP10. You'll now

glue this in between the fuselage

sides, making sure it's tabs are

fully inserted to the corresponding

slots pre-cut into both sides of the

fuselage.

■

Step 93 - Fuse Assembly (servo rails)

Now go back to step 89 and repeat everything you just did, so now

you can mount the servo into the other fuselage side.

■

Step 94 - Fuse Assembly (F4)

Locate the F4 assembly and the starboard

fuselage side. Place the fuse side with the

plywood upwards, nose pointed to the left

and tail to the right - just as in this photo.

Glue F4 in place, into the slots pre-cut into

the plywood sides. Note it's orientation and

make sure that the F4's support pieces face

towards the rear of the fuselage, as pictured here.

■

Step 95 - Fuse Assembly (F3)

Locate the F3/TR1 assembly. Glue F3 in place,

into the slots pre-cut into the plywood sides

and the bulk of the TR1 facing towards the

nose.

Note that TR1's tabs will not necessarily fi t

into the fuselage side yet, as it tapers toward

the front. Don't worry about this right now, as

that will be taken care of in a few steps.

■

Step 96 - Fuse Assembly (CS8/CS9)

Time to glue in the CS8/CS9 sandwiches.

Make sure they are completely inserted into

the plywood sheet. Also make sure they are

perfectly perpendicular to the ply in both

directions.

■

Step 97 - Fuse Assembly (WH6/WH7)

Now it's time to glue in the Texas toast

assembly of WH6/WH7. Make sure the tabs in

Wh6 are completely inserted into the plywood

sheet's slots. Also make sure it is perfectly

perpendicular to the ply in both directions.

■

Step 98 - Fuse Assembly (F1/F2)

Remember that we told you not to worry about

the taper in the TR1 piece? Well, now we're going to tackle part

of that.

Grab the F1/F2 fi

rewall

assembly and test fi t this to

the front of TR1. At the same

time you can bend the front

of the fuselage sheeting see

that the tabs in the tray and

the fi rewall will fi t into the

slots pre-cut into the side

sheeting.

When you see how this will work, mix up a little epoxy to glue these

pieces together.

Make sure you do NOT introduce any twist into

the fuselage side when doing this.

■

Step 99 - Fuse Assembly (port fuselage side)

Now it's time to attach the port fuselage side to the starboard

assembly. This is gonna take a bit of time, and we recommend

doing this in two steps.