16

Loading Paper

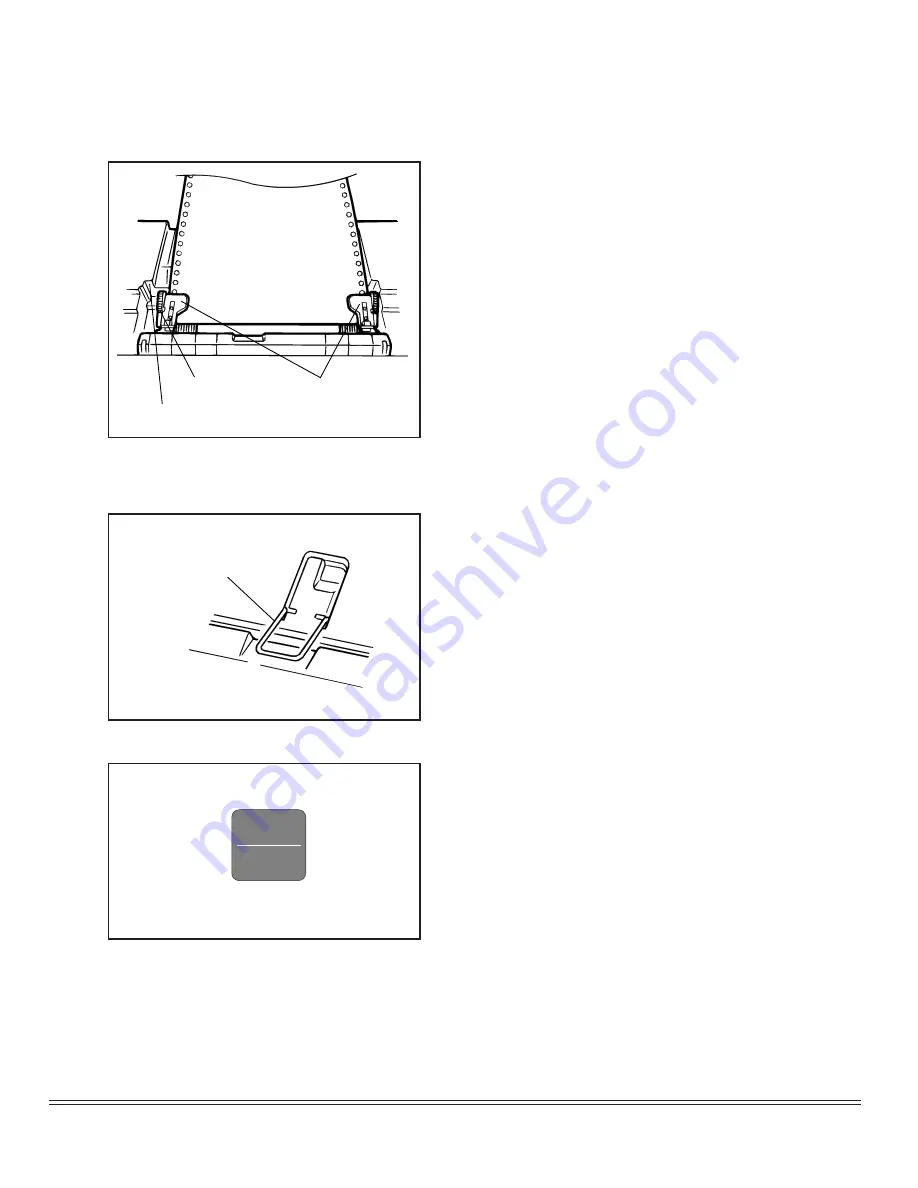

7. Close tractor covers and adjust left trac-

tor to position edge of paper: reference

marks on printer indicate left edge po-

sition for the two most common paper

sizes. When paper is properly aligned,

lock left tractor in place by pushing back

on lock lever.

8. Adjust right tractor so that paper holes

are centered on pins(careful – if paper

is stretched too tight or left too loose, it

can jam and cause problems), then lock

right tractor in place by pushing back

on lock lever.

9. Set Paper separator and swing wire feed

guide over to rest on pull-up roller as-

sembly to prevent from curling back

into printer.

10.Push FF/LOAD button. Paper will au-

tomatically feed into printer and

ALARM light will go out.

Tractor covers

Lock lever

Reference marks

Wire feed guide

FF/LOAD

Micro Feed

Up

ITEM

Summary of Contents for Microline 320 Turbo D1

Page 1: ...MICROLINE 320 321 TURBO Printer Handbook...

Page 9: ...2 Introduction...

Page 29: ...22 Loading Paper...

Page 53: ...46 Operation...

Page 57: ...50 Working with Software...

Page 85: ...78 Appendix B Menu Selections...

Page 99: ...92 Appendix D ASCII Character Codes Lower ASCII Character Sets 2 4...

Page 100: ...ML320 321 Turbo Printer Handbook 93 Lower ASCII Character Sets 3 4...

Page 101: ...94 Appendix D ASCII Character Codes Lower ASCII Character Sets 4 4...

Page 102: ...ML320 321 Turbo Printer Handbook 95 Upper ASCII Character Sets Upper ASCII Character Sets 1 4...

Page 103: ...96 Appendix D ASCII Character Codes Upper ASCII Character Sets 2 4...

Page 104: ...ML320 321 Turbo Printer Handbook 97 Upper ASCII Character Sets 3 4...

Page 105: ...98 Appendix D ASCII Character Codes Upper ASCII Character Sets 4 4...

Page 106: ...ML320 321 Turbo Printer Handbook 99 Epson International Character Substitutions...

Page 107: ...100 Appendix D ASCII Character Codes IBM International Character Substitutions...

Page 108: ...ML320 321 Turbo Printer Handbook 101 MICROLINE International Character Substitutions...

Page 110: ...ML320 321 Turbo Printer Handbook 103 Code Page Character Sets 2 4...

Page 111: ...104 Appendix D ASCII Character Codes Code Page Character Sets 3 4...

Page 112: ...ML320 321 Turbo Printer Handbook 105 Code Page Character Sets 4 4...