Moving or Transporting the Machine

- 73 -

2

1

3

4

5

6

7

6

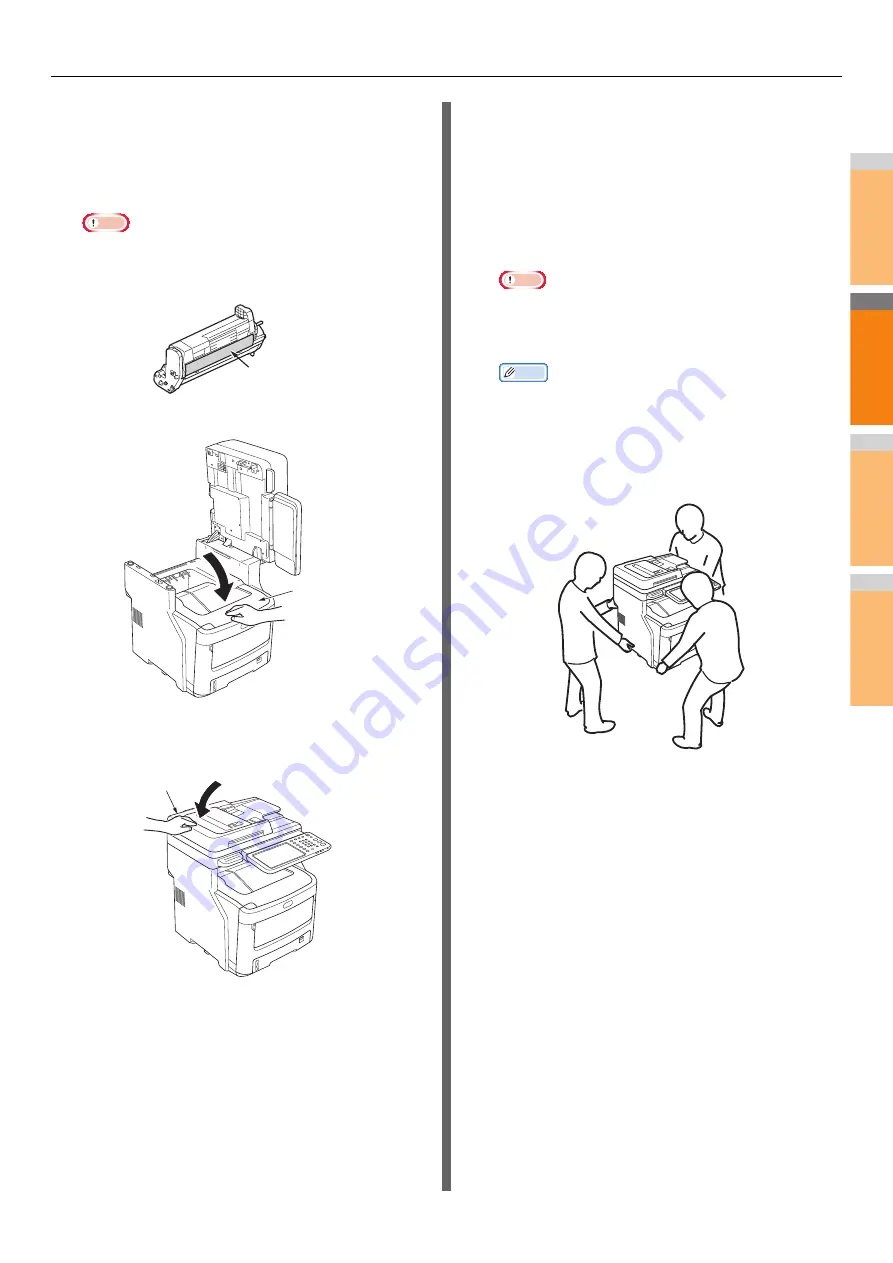

Use vinyl tape to cover the junction of the

image drum cartridge and toner cartridge.

Do this on each of the four image drum

cartridges, then put them back in the

machine in their original positions.

Note

• The image drum cartridges should be kept inside the

machine when transporting. Seal them with vinyl tape

to prevent toner from spilling.

7

Close the top cover.

8

Return the scanner part to its original

position.

9

Separate the main printer unit from any

additional tray units.

If there are no additional tray units, proceed to step 10.

The separation procedure is the exact opposite of

installation. For more information, refer to the

Setup

Guide

.

10

Protect the machine with cushioning

material.

Note

• Use the original box, packaging, and cushioning

material that came with your machine at the time of

purchase.

Memo

• When setting up the machine again after transport, be

sure to remove the tape from each of the image drum

and toner cartridges.

11

At least three people should lift the

machine unit and place it in the box.

Vinyl Tape (back

side as well)

Top cover

Scanner part

Summary of Contents for ES7470x MFP

Page 1: ...User s Manual Troubleshooting Guide...

Page 74: ...2 1 3 4 3 Appendix Battery Disposal P 75...

Page 76: ...2 1 3 4 4 Index...

Page 78: ...July 2014 45510802EE Rev3...