-

8

-

5-2.

Basic operations

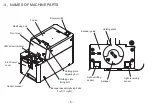

○Loading the screws

・

Turn the power switch ON and OFF so that the brush stops vertically above

the rail.

・

Open the top cover and load screws on the left and right side of the rail

evenly.

・

Do not load screws above the surface of the rail.

・

Be sure to determine the screw load by observing the machine while it is in

operation.

Screws with a diameter larger thanφ5 or longer than 20mm,

under the head, should not be loaded higher than the rail bottom.

○Turning ON the power

・

Use only the adapter supplied with this machine to connect it to a wall outlet.

When you turn the power on, the switch lamp lights up, the motor rotates and

screws are scooped onto the rail.

・

The rail vibrates to deliver screws towards the end of the rail, then the

escaper rotates to deliver screws to the pick up spot. When the screws come

to the stopper, the LED indicator lights up and the escaper stops rotating.

Rail cover

(INDICATION:The maximum screw load must not be over

30mm below the rail-groove surface.)

Disassembled state

Do not load screws

above this point.

(Rail Bottom)

Rail cover

[CAUTION]

Use only the AC adapter supplied with this machine

otherwise it may cause damage to the machine.

[CAUTION]

・

The type and length of screw changes the load capacity so check and adjust

the load accordingly.

・

Do not overload the hopper with screws otherwise it may cause a

malfunction or damage the machine.

・

This machine accepts only steel screws. Plastic or stainless screws are not

accepted.

Summary of Contents for OM-26RB Series

Page 23: ...22...