―

91

―

HXPRM10mnC0001E

8.2.5 Outputting the Status

If the open-link recorder has a data error on its link, it will save the error as a communication error in

the internal status area.

The (ESC S) command reads this status. Issuing this command clears the

on-going error.

1) Status Output Command

ESC S(CR)(LF)

Receiving this command outputs the status for the command received so far.

2) Status Output

XX :

00~19

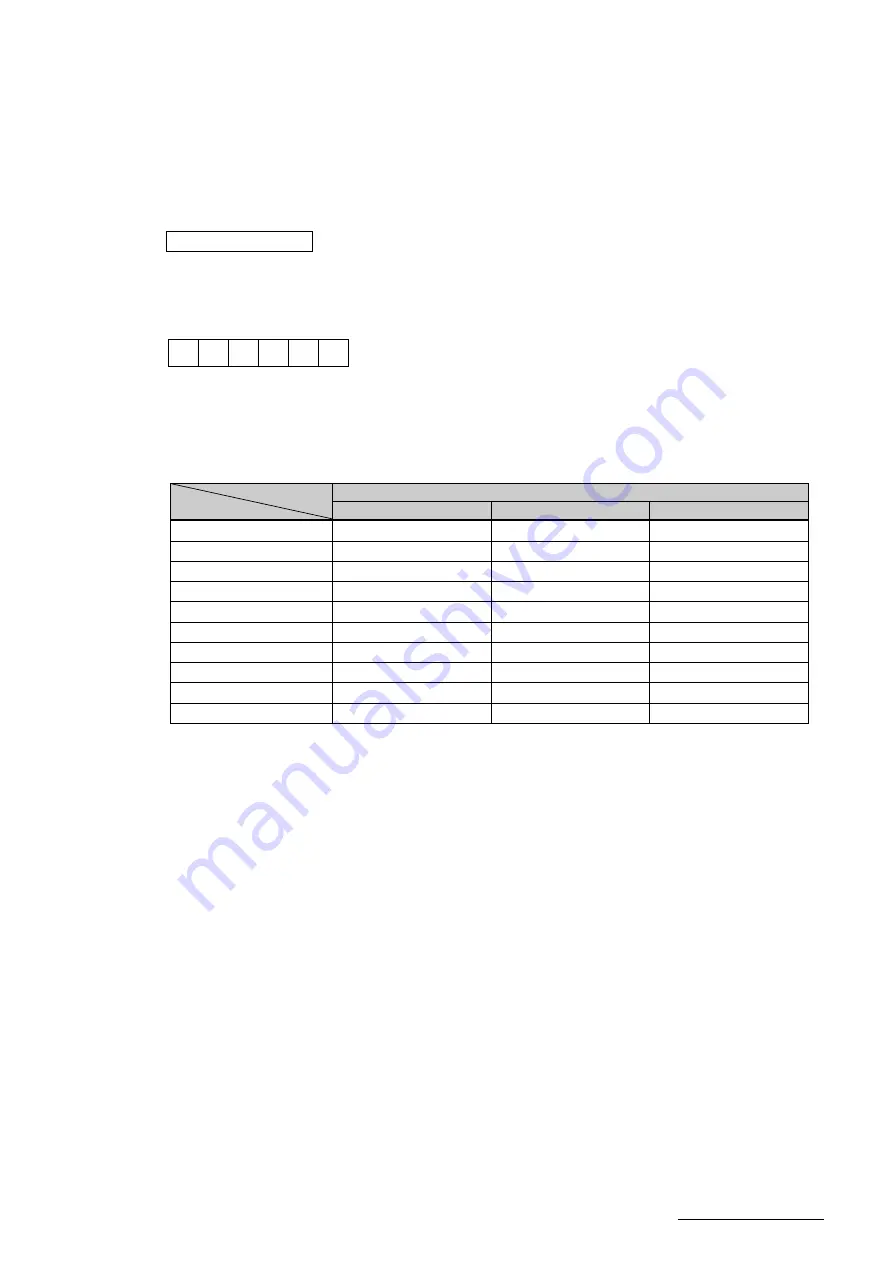

Table 8.1 Status output list

Status factor

Status output

Status factor

A/D

END

Syntax error

Paper empty

ER 00 C

R

L

F

ER 01 C

R

L

F

○

ER 02 C

R

L

F

○

ER 03 C

R

L

F

○

○

ER 04 C

R

L

F

ER 05 C

R

L

F

○

ER 16 C

R

L

F

○

ER 17 C

R

L

F

○

○

ER 18 C

R

L

F

○

○

ER 19 C

R

L

F

○

○

○

○:

The factor from which status is ENABLE.

A/D END

:

When carring out AD conversion end, it occurs.

Syntax error

:

It occurs during a communication error or a command error occurs.

Paper-empty

:

When Paper-empty is found, it occurs.

(The Paper-empty option has been attached)

E

R

X

X

CR

LF