3

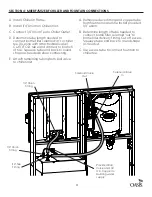

3. OVERLOAD PROTECTION (systems with chiller)

The compressor motor is equipped with an automatic reset protector which will disconnect the motor from

the line in case of overload.

4. LUBRICATION (systems with chiller)

This unit is equipped with a hermetically sealed compressor. No additional lubrication is required. The fan

motor installed on this unit seldom needs oiling. If required, a few drops of SAE 10 oil should be used.

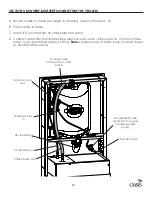

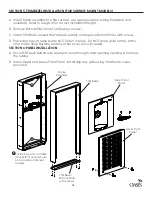

5. TO DISCONTINUE USE OF SYSTEMS WITH CHILLER

Drain cooler when removed from service: (1) Remove grille, (2) Close supply valve, (3) Provide container to

catch water, and remove drain plug.

6. MAINTENANCE (systems with chiller)

The only maintenance required is the removal of dirt and lint from the condenser. Inspection should be made

at 3 month intervals. Remove the grille and clean the condenser with a vacuum attachment. WARNING: The

warranty and Underwriters’ Laboratory Listing for this machine are automatically voided if this machine is

altered, modified, or combined with any other machine or device. Alteration or modification of this machine

may cause serious flooding and/or hazardous electrical shock or fire. EXCEPT AS SET FORTH HEREIN, THE

MANUFACTURER MAKES NO OTHER WARRANTY, GUARANTEE OR AGREEMENT EXPRESSED, IMPLIED, OR

STATUTORY, INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

Summary of Contents for Modular Series

Page 17: ...17...