2

OASIS AQUA POINTE® ELECTRONIC BOTTLE FILLERS INSTRUCTIONS

1. INSPECTION

Inspect the cartons and various components for evidence of rough handling and concealed damage.

Damage claims should be filed with the carrier.

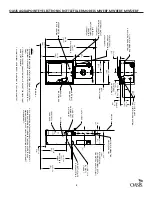

2. INSTALLATION, PLUMBING & ELECTRICAL CONNECTIONS

a)

Note: The following states require a licensed plumber to install cooler; AR, GA, MA, MI, OK, RI, SC,

SD, TX, VT and WI. CA, KS, MN, NM and OR allow for a state-registered installer or contractor as well. State

and local plumbing codes may prohibit the use of saddle tapping valves for water line connection in some

applications. All connections must conform to applicable plumbing codes.

b)

Plumbing rough-in and wall opening should be prepared as shown on roughing-in drawing. This

drinking water cooler is designed to be operated at a water supply line pressure of up to 100 psi (690 kPa).

A pressure regulator must be installed in front of the unit’s water inlet if the pressure (including any possible

pressure spikes) could exceed 100 psi (690 kPa).

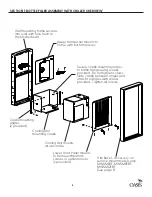

c)

Insert frame assembly into wall opening and secure to studs. NOTE: FRONT FLANGE OF FRAME(S)

MUST BE FLUSH WITH THE FINISHED WALL SURFACE.

d)

Install drain receptor to frame with screws provided.

e)

A 2X4 junction box is provided for the installation of a 115 volt receptacle. The bottle filler is provided

with a power cord with a grounded NEMA 15 plug. This unit is intended to be connected to a ground fault

circuit interrupting (GFCI) device to meet UL requirements. It is recommended that flexible conduit be used to

supply power to the junction box and chiller if used. Check the electric current available. Type and voltage

must be the same as listed on the unit data plate.

f)

As the bottle filler panel assembly is being placed on the frame assembly, feed the long green

ground wire and the terminals on the power supply cord through the bushings in the frame assembly.

g)

Attach the long green ground wire to the frame assembly junction box ground, then plug in bottle

filler power cord.

h)

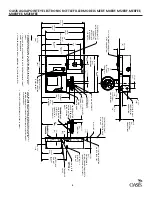

Refer to the appropriate connection diagram for water and drain connections. Check for leaks.

i)

The lower panel can be secured with the provided key locks or screws. The M8EBF features one

lockable and one non lockable lower panel; these are interchangeable.

MODELS WITH CHILLER

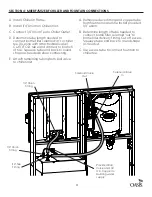

j)

Attach cradle mounting angles to unit mounting cradle with 4 screws provided. Slide unit mounting

cradle into frame and secure in place with 4 screws, provided. (Cradle is used only when cooling unit is to be

installed). NOTE: BOTTOM FLANGE ON CRADLE IS TO BE BEHIND FRAME FRONT FLANGE.

k)

Slide cooling unit onto cradle.

M8EBF & M12EBF WITH FOUNTAIN

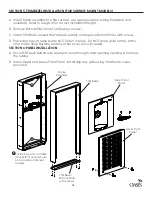

l)

Install the fountain mounting plate to the frame assembly using the provided screws.

m)

Place the upper panel in place on the frame top angle and fasten with 2 screws, provided, at the

bottom.

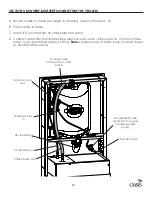

n)

Remove the bottom plate from the fountain arm. Save the screws.

o)

Snap the reveal gasket over the back end of the fountain arm.

p)

Add compression connector, furnished by others, to the fountain waste tube and slide back

approximately 3” out of the way. Refer to the appropriate connection diagram.

q)

Hang the fountain on the mounting plate studs. NOTE: AS THE FOUNTAIN IS HUNG, FEED THE WASTE

TUBE INTO THE WASTE STUB ON THE WALL SIDE.

r)

Tighten the fountain to the mounting plate with the 5/16-18 nuts and washers and the 1/4-20 bolts

and washers provided.

s)

Slide the reveal gasket(s) back into the notch between the panel and the arm. The gasket serves as

an appearance item only (to close up any opening around the panel and the mounting plate).

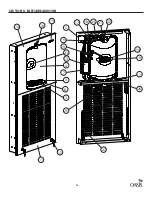

Summary of Contents for Modular Series

Page 17: ...17...