6

There are two methods of installing the engine in the aircraft:

(a) standard beam mounting, using the engine's integral

crankcase mounting lugs, and (b) radial mounting, using the

backplate mount supplied, to bolt the engine to the front

bulkhead or firewall. Whichever method is chosen, make sure

that the structure to which the engine is attached (i.e.

horizontal bearers or vertical bulkhead), is of sturdy

proportions and very firmly integrated with the airframe. This

is necessary both for safety and for the realisation of

maximum performance.

INSTALLATION

Beam mounting

Use heavy, rigid, hardwood bearers or a metal mount and

keep unsupported length as short as possible to reduce

frontal overhang.

Make sure that the bearers are parallel and that their

mounting surfaces are in the same plane.

Use 5mm or 10-24 steel cap-head screws, such as Allen

hexagon socket type, with locknuts, for bolting the engine

to the bearers.

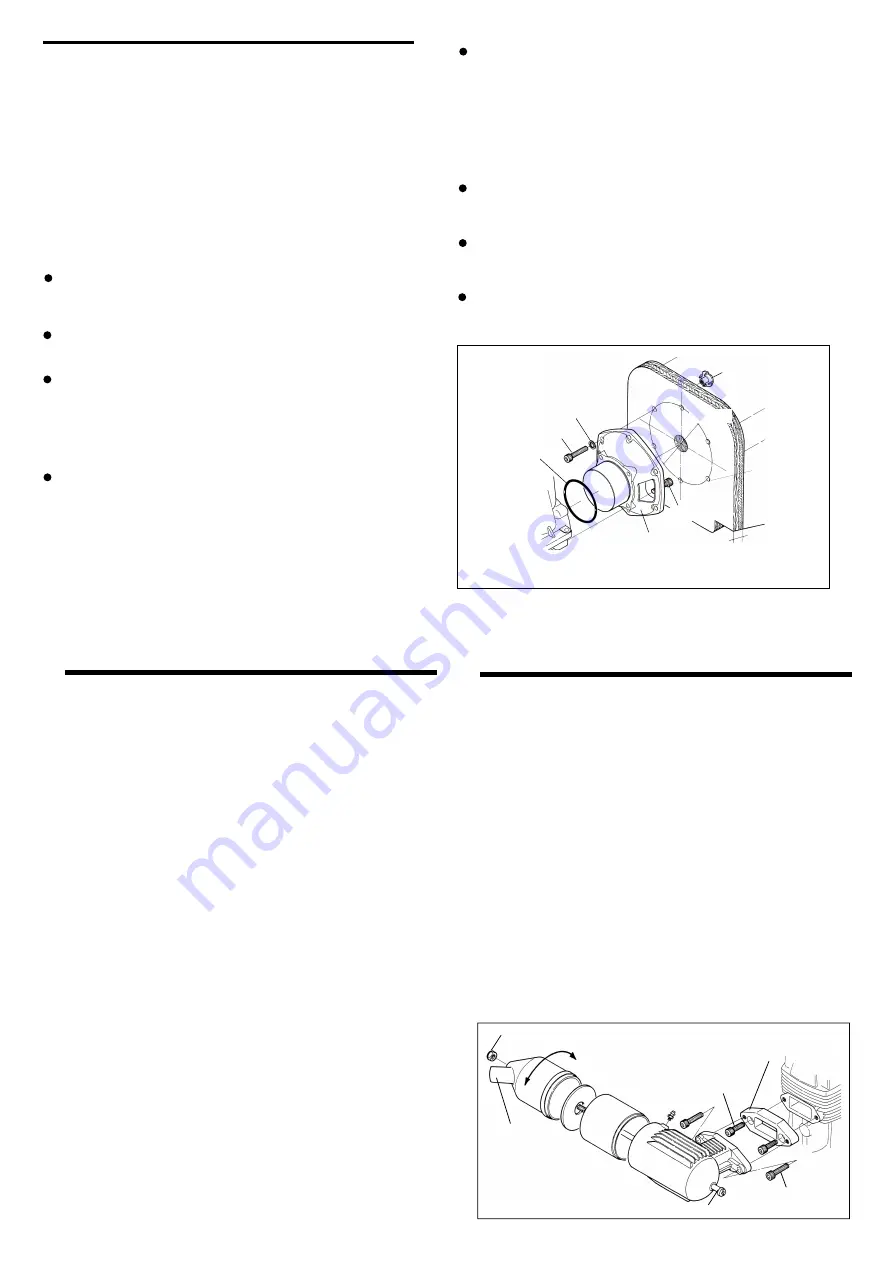

Radial mounting

Draw vertical and horizontal centre lines on the firewall to

correspond with the required thrust-line. Use these to find

the centre of the 100mm (3.93 in.) diameter bolt-circle

required to correctly locate the backplate mount.

Depending on whether the engine is to be installed with

the cylinder upright, inverted, angled or horizontal, position

the backplate mount so that the access hole in the side of

the mount is conveniently located to receive the fuel line

and muffler-pressure line from tank to engine. Place the

mount against the firewall so that its six mounting holes

are accurately aligned on the bolt ciircle. Mark off the bolt-

hole centers and drill six 6.5mm holes through the firewall.

Remove the crankcase cover plate from the engine.

Carefully slide the O-ring seal from the cover plate and fit

it, to the retaining groove on the backplate mount.

Fit the backplate mount to the engine in the required

position and secure it firmly with the four M5x22 Allen

screwa provided.

Bolt the complete engine and backplate mount assembly

to the firewall, using the six M5x25 Allen screws, toothed

lock washers and blind nuts supplied.

Firewall

Toothed lock washer

M5x25

O-ring

Backplate mount

At least 15mm rigid

hard plywood

M5 Blind nut

6.5mm hole

M5x22

100mm

7

Before connecting the throttle-lever / servo linkage, make

sure that no part of the linkage interferes with the internal

structure of the aircraft or wiring, etc., when the throttle is

fully open or fully closed.

Set the throttle lever linkage so that the throttle rotor is (a)

fully open when the transmitter throttle stick is fully

advanced and (b) fully closed when the throttle stick is fully

retarded. Adjustment of the throttle rotor opening at the

idling position can then be made with the throttle trim lever

on the transmitter. (Select throttle-lever and servo-horn

hole positions that will avoid excessive pushrod travel

causing the throttle to bind at either end.)

THROTTLE LINKAGE

When adjusting the throttle lever angle, relative to the

rotor,hold the rotor at about half-way between the open

and closed positions while loosening and tightening the

fixing screw, otherwise the rotor, rotor guide

screw,throttle stop screw or carburetor body may

become burred and damaged.

Note:

•

•

INSTALLATION OF SILENCER(MUFFLER)

To fit the standard silencer

Fix the exhaust adaptor plate to the engine with the two M5

x15 Allen screws supplied.

1.

Now fit the silencer to the exhaust adaptor with M5x20

Allen screws, also provided.

2.

In order to prevent the leakage of exhaust oil from

between the engine and adaptor, and between the

adaptor and silencer, apply a suitable silicone sealant to

the joint faces during assembly.

NOTE:

The angled exhaust outlet is agjustable and can be rotated to

any desired position in the following manner.

Loosen locknut and assembly screw.

Set the exhaust outlet at the required angle by rotating the

rear part of the silencer.

Re-tighten the assembly screw, followed by the locknut.

1.

2.

3.

M5x15

M5x20

Lock nut

Exhaust Outlet

Turn to required position

Exhaust adaptor

Assembly screw