15

INSTALLATION IN EXISTING CONSTRUCTION (

CONT

'

D

)

WALL INLET INSTALLATION (

CONT

'

D

)

M

AKING

THE

W

ALL

I

NLET

C

UTOUT

(

CONT

'

D

)

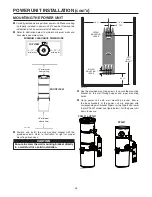

Place the template against

the wall so that it is 18”

on-center from the floor.

Use a level along the top

edge of the template to

make sure it is square to

the wall. Mark your wall

for the cutout by tracing

around the inside of the

template. Then use your

pencil to mark the screw

hole locations through

punched holes at the top

and bottom of the template.

Remove the template from

the wall.

Use an awl or icepick to

punch pilot holes where

you marked the two hole

locations. Now, drill two

3⁄8” diameter holes, using

the pilot holes as the

centers. Locate and drill

these holes exactly as

marked with the template.

Also drill four pilot holes

in the four corners of the

marked area. Make sure

these holes are located

inside the marked line.

Then, using a utility knife,

score along the inside of

the marked line. For plaster

walls, score the plaster

deeply, being careful to

stay inside the marked line.

Next, use a keyhole saw

or a sabersaw to make the

cutout. Again, be extremely

careful to cut along the

inside of the marked line.

A

TTACHING

THE

I

NLET

M

OUNTING

P

LATE

Reach through the inlet

hole and locate the inlet

tubing. Raise it up inside

the wall until you locate

the inlet tubing. If the inlet

is connected from the

basement, have a helper

insert the inlet tubing into

the access hole until you

can see the flexible tubing.

Then, pull the flexible

tubing through the inlet

hole and remove the low

voltage wiring from inside

the tube. If the end of the flexible tubing is not even, trim it so

that it is exactly even.

Now, remove the nail

flange (used for new

construction) from the inlet

mounting plate. Use pliers

to bend this flange along

the scored lines until you

can break it off.

Apply cement to both the

inside of the flexible tubing

and to the outside of the

mounting plate’s tube ring.

Insert the mounting plate’s

tube ring in the flexible

tubing and twisting the

pieces as you join them

to spread the cement, and

align the mounting plate in

a vertical position.

Hold the assembly in place for a few minutes as the cement

sets; allow 5 minutes for the cement to completely dry.

Now, strip the ends of the two low voltage wires, and then

connect the wires to the screw terminals on the back of the

inlet cover. Make sure the wires are tightly secured under the

terminal screws.

AR0027

3/8”

DIA.

HOLES

AR0028A

Pilot holes must be

inside marked line

AR0032A

Cut

along

inside

of marked

line

AR0033A

CAUTION

When cutting into

plaster walls, make

sure the plaster is firm

and secure around

the cutout area.

AO0038

Nail Flange

AO0039A

AO0040

AO0041

AO0042