OPI_TOP LIFT TSK 8000_V3.2_EN

23

6 Behaviour in cases of error

Defective operational readiness of the lift may be

due to a simple error. Check the system for the list-

ed sources of error.

If the error cannot be removed after an inspection

to the named causes, then inform customer service

or your dealer.

Independent repair work on safety

devices of the lift and checking the

electrical system may only be done

by specialists.

Problem: Motor does not start

Possible causes:

Remedy:

No power supply

Check the power supply

The main switch is not

switched on, or is de-

fective

Check main switch

Defective fuse

Have fuses checked

Power supply interrupt-

ed

Inform customer service

Thermal fuse of the mo-

tor is active

Let motor cool (cooling

time dependent on am-

bient temperature)

Motor defective

Inform customer service

Problem: Motor starts, load is not lifted

Possible causes:

Remedy:

The vehicle is too heavy Unload vehicle

Hydraulic oil filling level

is too low

Refill hydraulic oil

The emergency dis-

charge screw is not

closed

Check the emergency

discharge screws

Hydraulic valve defec-

tive

Inform customer service

Mechanical pump de-

fective

Inform customer service

The coupling between

the motor and pump is

defective

Inform customer service

Problem: The lift cannot be lowered

Possible causes:

Remedy:

Lifting table is sitting on

an obstacle

See Section 6.1

Hydraulic valve defec-

tive

Inform customer service

Defective fuse

Have fuses checked

Push button defective

Check push button

6.1 Moving onto an obstacle

If the lift drive-on rail/lift arm moves onto an obstacle

during lowering, then it remains in position due to the

mechanical resistance. By pushing the "Lift" button,

the lift can be raised again to remove the object.

6.2

Emergency discharge with external unit

and safety latch

An emergency discharge is an ac-

cess into the lift controls and may only

be done by experienced specialists.

The emergency discharge must be

done in the following described se-

quence, otherwise it can lead to

damage and hazard to life and limb.

Any kind of external leakage is not

permitted and must immediately tak-

en care of. This is absolutely neces-

sary especially before an emergency

discharge.

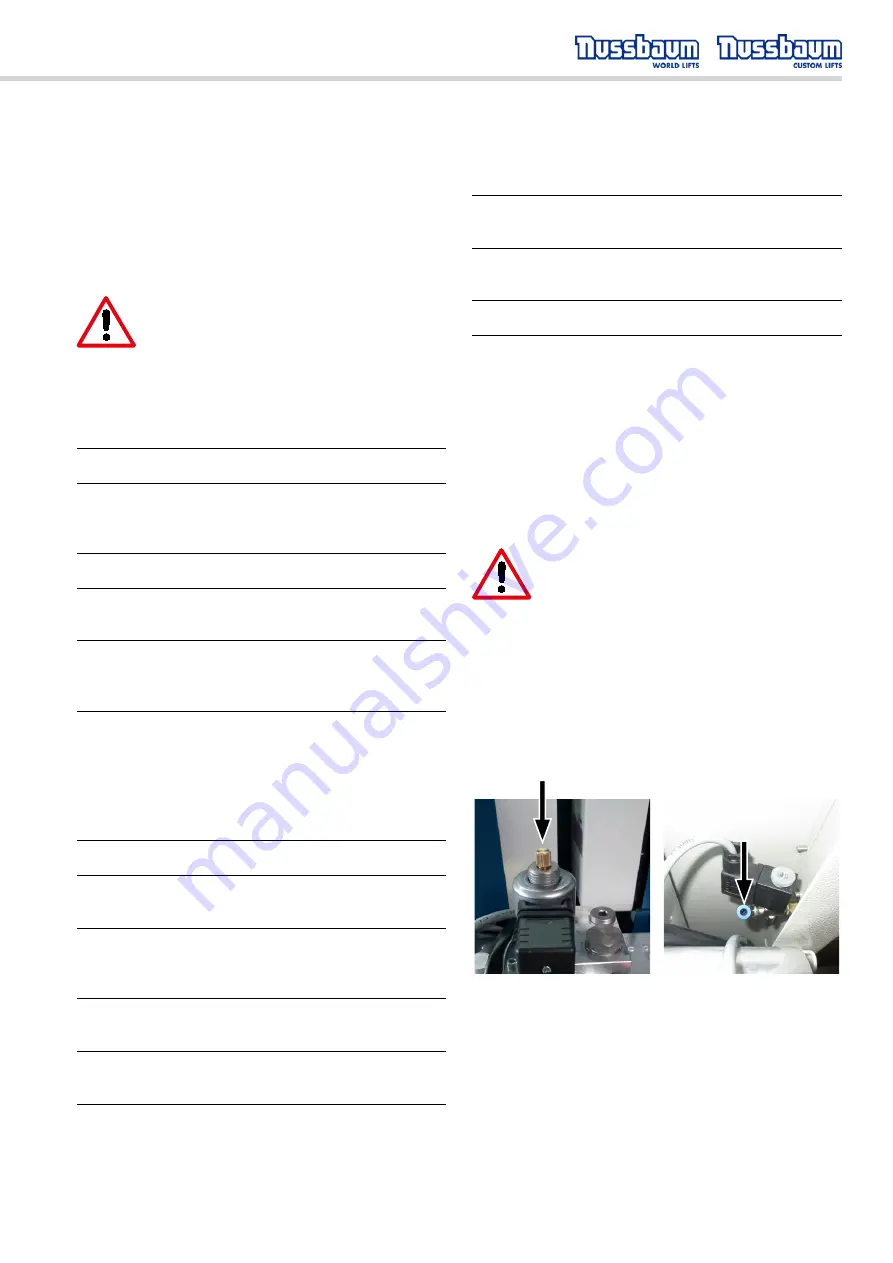

Fig. 2a (left): Hydraulic emergency lowering, re-move cap and

open valve

Fig. 2b (right): Pneumatic air supply for actuating the ratchet

cylinders.

6.2.1 Defect of the hydraulic valve

If there is a defect in the hydraulic valve there is still

the option of moving the lift to its lowest position so

the vehicle can be drive off the lift.

1. Push the “Lower” button and the latches must

unlock.

Summary of Contents for TSK 8000

Page 2: ...2 OPI_TOP LIFT TSK 8000_V3 2_EN...

Page 4: ......

Page 9: ...OPI_TOP LIFT TSK 8000_V3 2_EN 9...

Page 20: ...20 OPI_TOP LIFT TSK 8000_V3 2_EN...

Page 44: ...44 OPI_TOP LIFT TSK 8000_V3 2_EN...

Page 45: ...TOP LIFT TSK 8000 Serial No Made in Germany Spare parts list...