nuaire.co.uk

029 2085 8200

BOXER BPS

ECOSMART CLASSIC CONTROL (ES)

nuaire.co.uk

029 2085 8200

8.0 SETTING TO WORK USING THE TEST

BUTTON ECOSMART CONTROL

The test button allows the individual blowers within the unit to be checked for

its operation. If the fan is running already, press the button once to stop the fan,

press again to switch on the fan.

Note that the fan will return to normal operation after 30 seconds.

LED Indication

Settings

BMS Input signals

PWR

GREEN: Power on & OK,

Standby LED on when fan is not running.

Fan 1

GREEN: Fan 1 is running, RED: Fan 1 faulty.

Fan 2

GREEN: Fan 2 is running, RED: Fan 2 faulty.

Heating* GREEN: Heating selected RED: Heating faulty.

Cooling* Not applicable. See note.

Fault

LED on when a fault is present on unit.

Frost*

Not applicable. See note.

TX

LED on when the controller is transmitting data.

RX

LED on when the controller is receiving data.

* Note that the control panel is common to all the Ecosmart products and

will have indicators for functions that are not available in this particular

fan. However these indicators will not be illuminated.

The system’s response to a 0-10V dc BMS signal is given in the

following table.

Note the BMS signal will override any sensors and user control

connected in the system. The voltage tolerance is +/_ 125mV and is

measured at the fans terminal.

Ventilation

Cooling mode *

Heating mode *

Local Control

0.00

-

-

OFF / Trickle

0.25

-

-

Speed 1

0.50

0.75

1.00

Speed 2

1.50

1.75

2.00

Speed 3

2.50

2.75

3.00

Speed 4

3.50

3.75

4.00

Speed 5

4.50

4.75

5.00

Speed 6

5.50

5.75

6.00

Speed 7

6.50

6.75

7.00

Speed 8

7.50

7.75

8.00

Speed 9

8.50

8.75

9.00

Speed 10

9.50

9.75

10.00

Setting the maximum airflow

Setting the maximum trickle airflow (nominal 40%)

Setting the overrun time

Setting the trickle ventilation facility

Setting the ‘air off’ temperature

i) Ensure the power supply is switched off and that a link wire is

connected from the supply L to the SL terminal.

Unplug all items connected to the ‘Net‘ connectors.

ii) Switch on the power supply.

iii) Wait for the fan to complete its self-test operation.

Measure the airflow using standard commissioning instruments at a suitable

point in the ductwork. If adjustment is required, rotate the pot marked ‘MAX’ to

obtain the desired airflow.

i) Repeat the same procedure as for maximum airflow above but

without the link wire between supply L and SL terminal. Ensure

the trickle switch is in the ‘ON’ position. Adjustment must be made on the

pot marked ‘Min’.

ii) Note that the minimum setting (nominally 40%) must be below

the maximum setting, otherwise minimum setting will be

automatically set to be the same as the maximum.

A switched live of 100-230V at terminal SL will activate the fan. When the

switched live signal is removed the fan will overrun for period set by the dial ‘SL

run on’ - adjust the desired overrun time by rotating clockwise.

Slide the ‘trickle’ switch 0 = Off, 1 = On. With ’trickle’ on and power to unit the

fan will run at minimum speed until the switch live signal activates it to boost.

The adjustment knob is located in the control pack and must be set to the

desired ‘air off’ temperature.

LED indicators

Min Max SL run on

Trickle Test

0 1

Pwr

Standby

Fan 1

Fan 2

Heating

Cooling

Fault

Frost

TX

RX

Co

nnector

Ecosmart

MIN

= Minimum speed

adjustment

MAX

= Maximum speed

adjustment

SL run on

= Switched Live

Run-On Timer

adjustment

TRICKLE

= Selects trickle

running: 0 = off,

1 = selected

TEST

= Test button

Figure 17: Ecosmart commissioning board

*Only available on relevant unit

8.1 ECOSMART FROST PROTECTION

Ecosmart frost protection is activated on any AHU fitted with LPHW heating,

when the outlet air temperature is 4ºC or below.

The unit reacts by shutting down the fan to prevent a ‘wind chill’ effect reducing

the temperature to a point whereby the coil could freeze and burst. The unit will

also drive open the LPHW valve to a fully open position to allow full water flow

through the coil and the main PCB will close the ‘Heat demand’ contacts. These

contacts could be used to send a signal to activate the boiler and/or valve to

open to provide heat if not already doing so.

Summary of Contents for BOXER B815H Series

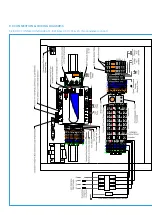

Page 19: ...Figure 18...

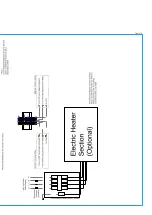

Page 21: ...21 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 21 Figure 19...

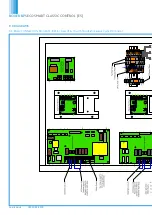

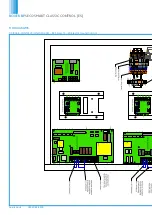

Page 23: ...23 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 23 Figure 20...

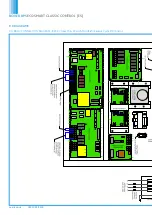

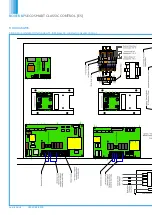

Page 25: ...25 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 25 Figure 21...

Page 27: ...27 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 27 Figure 22...

Page 29: ...29 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 29 Figure 23...

Page 31: ...31 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 31 Figure 24...

Page 33: ...33 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 33 Figure 25...

Page 35: ...35 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 35 Figure 26...

Page 37: ...37 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 37 Figure 27...

Page 39: ...39 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 39 Figure 28...

Page 47: ...47 04 11 19 Leaflet Number 671827 BOXER BPS ECOSMART CLASSIC CONTROL ES 47 NOTES...