Lx Series Installation and Operation Instructions

│

Trinity Lx

33

9.0

GAS VALVE AND BURNER SET-UP

The Trinity Lx gas valve must be set-up by a licensed Gas Technician. Improper set-up

may result in incorrect operation, damage to components or property, injury or death.

Gas Line Pressure

The appliance gas valve is equipped with a line pressure test port; see Figures 9-1 through 9-4. Use the following

procedure to measure the gas line pressure to the appliance to ensure if falls within the range given in Table 9-1:

1.

Turn the supply of gas to the appliance off.

2.

Open the bleed screw of the line pressure test port approximately 1-1/2 turns (Lx150-400 models). This

port is directly connected to the gas line feeding the appliance. For Lx800 models, replace 1/8” NPT plug in

the inlet flange of the gas valve with a hose barb fitting suitable for manometer tubing used. See Figure 9-4.

3.

Force 1/4

"

ID tubing over the housing of the line pressure test port; install the other end of the tubing to an

appropriate line pressure test gauge or manometer. Ensure both ends of the tubing make a tight connection.

4.

Open the supply of gas to the appliance and check for gas leaks.

5.

Observe the line pressure under static conditions and compare it to Table 9-1. The pressure will be greatest

under static conditions.

6.

With all other gas appliances in the applications running, operate the burner to the maximum firing rate

(See Table 9-2) and compare the observed line pressure with Table 9-1. The pressure will be lowest during

the maximum flow of gas.

7.

Adjust the gas line pressure to ensure the parameters in Table 9-1 are attained under all conditions. If

possible adjust the line pressure to the "Nominal/Desired" value listed in Table 9-1, while the unit is

operating at the maximum modulation rate, see Table 9-2.

8.

Continue observing the gas line pressure until the completion of the combustion analyses, incase

adjustments need to be made.

9.

Upon completion of the line pressure testing, return the bleed screw of the Line Pressure Test Port to the

closed position. For the Lx800, replace the installed hose barb fitting with the factory 1/8” NPT plug; use

NG/LP approved thread sealant.

The line pressure is a function of the gas supply and is affected solely by field provided

parameters such as line size and regulator settings. Under no circumstances can the

appliance gas valve influence or be used to adjust the gas line pressure.

Failure to close the bleed screw of the Line Pressure Test Port will cause a severe leakage

of gas, resulting in a fire or explosion causing property damage, serious injury or death.

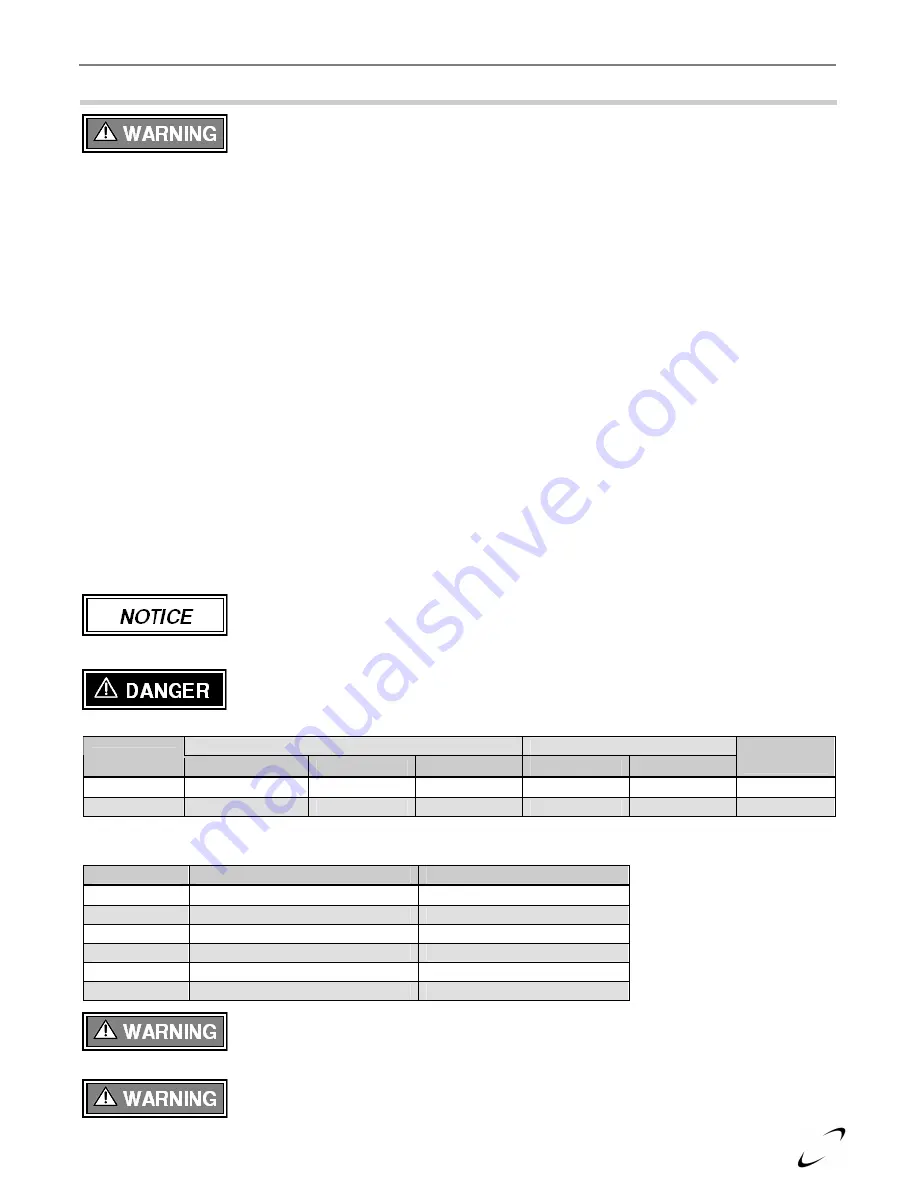

Table 9-1 Line Pressure and Combustion Parameters

Line Pressure (inches wc)

CO

2

(%)*

Gas

Nominal/Desired

Min.

Max.

Min.

Max.

CO (ppm)

Max.

Natural

7

4

10.5

8.5

9.5

175

Propane

11

8

13

9.5

10.5

175

*Note: it is permissible to have higher CO

2

values with the burner operating at the minimum modulation rate.

Table 9-2 Minimum and Maximum Modulation Rates

Model

Min. Modulation Rate (RPM)

Max. Modulation Rate (RPM)

Lx150

1150

5850

Lx150E

925

4450

Lx200

925

5950

Lx300

1250

5850

Lx400

1550

7250

Lx800

1250

5300

Carbon Monoxide - Never leave the unit operating while producing Carbon Monoxide

(CO) concentrations in excess of 175ppm. Failure to follow this warning may result in

serious injury or death.

Manifold Pressure - DO NOT adjust or measure the Manifold Pressure of the appliance.

Correct manifold pressure is factory set. Field adjustment could result in improper burner

operation resulting in fire, explosion, property damage or death.