17

surface. When the blade meets the concrete surface at a 90° angle

(perpendicular) less side drag is created on the blade. When the blade is

not perpendicular side drag is create that will cause the concrete to chip or

spall.

3. Blade that is designed for green concrete cutting. The GMAX blade has

some unique features that make it an outstanding blade for green concrete

cutting such as:

a) Anchor Slot Core Technology that reduces vibrations in the blade.

Excessive vibrations will cause the blade to flutter or bend from side to

side which will damage the concrete surface and cause the blade to

wear out prematurely.

b) Thicker core that resist flexing and bending. Thin core blades bend

due to excessive pressure during cutting and from over heating. When

blade bends and flexes the concrete and blade will be damaged.

c) Optimized bond and diamond for fast green concrete cutting. The

improper bond will not cut green concrete properly.

When to Start Green Concrete Cutting

Timing is the most important aspect of cutting green concrete. The time that

the operator can start cutting will vary depending on the key factors listed

above. For example if the concrete has a high water to cement ratio or the

day is cooler then more time is required for the concrete to properly set up

and hold the aggregate in place. Typically we are finding that starting around

5 to 6 hours after finishing good results can be obtain. We find in our testing

that at 16 hours in gives the best results. These times to start are assuming

that the concrete has set up long enough to hold the aggregate in place.

Green Concrete Cutting Trouble Shooting

Spalling or Chipping On Both Sides of Cut:

1.

Wait

at least 1 to 2 more hours before cutting. The very good cut

appearance is achieved at 5 to 6 hours after finishing complete. The best

cut appearance occurs when the concrete has set up enough for the

aggregate to be held in place which may take up to 16 hours. The actual

time to begin cutting will depend on many factors such as: concrete

mixture (PSI, concrete type, sand type and amount, and other materials,

water to cement ratio – more water the longer the set up), aggregate size

and type, concrete additives – some speed up while others slow down the

set up time, environmental factors (Sun, wind, rain, temperature), concrete

temperature (Cooler the concrete the longer the set up time).

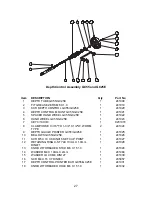

Summary of Contents for GC25E

Page 39: ...39 NOTES...