16

Green Concrete Cutting Important Considerations

Green concrete is concrete that is still in a plastic state that is the concrete

still has a lot of moisture in it, in other words it is not fully cured or dry. As the

concrete starts to hydrate (Dry or Cure), the concrete will change slightly in

volume. Concrete normally shrinks about 1/16” for each 10 feet during the

hydration process. This change in size creates internal stress in the concrete

which will develop into cracks. Joints also known as Crack Control Joints and

or Expansion Joints are normally cut into the concrete in order to relieve the

internal stress and to create an area where a controlled crack will occur. With

the joint in place the concrete will normally crack in a straight line underneath

the joint. The idea behind cutting the green concrete is that the sooner the

stress relieving joints are made the better control over the random cracking

will be obtained. For most green cutting the depth of cut is made at 25% of

the overall thickness of the concrete, for example if the concrete is 6” thick,

the cutting depth would be set to 1-1/2” deep. One important fact to

remember is that Green Concrete is any concrete that has set up but not

hardened. For concrete to become fully hardened it may take 5 to 7 days.

There are a few factors that affect green concrete cutting quality, and time

that the cutting can begin. The following list is extremely important to follow

and to understand in order to create a good quality cut with no spalling or

chipping of the cut line.

1. The concrete must set up long enough to hold the aggregate in place. If

not the aggregate will tumble and move when the Diamond Blade contacts

it, causing internal damage to the concrete and possible tearing or spalling

of the concrete surface. The aggregate along with the concrete must be

cut for proper crack control. With out proper set up the aggregate will roll

or move within the concrete creating voids and spalling or chipping of the

cut line will occur. Concrete set up is the MOST important issue to

obtaining a quality cut line when green concrete cutting. Factors that

affect the concrete set up are:

a) Concrete Mixture – PSI, concrete type, sand type and amount, and

other materials.

b) Water to Cement Ratio – more water the longer the set up

c) Aggregate Size and Type

d) Concrete Additives – some speed up while others slow down the set

up time.

e) Environmental Factors – Sun, Wind, Rain, Temperature

f) Concrete Temperature – cooler the concrete the longer the set up time.

2. Flat surface. Flat surfaces help to insure that the blade is perpendicular to

the concrete which reduces the chances of damaging the concrete

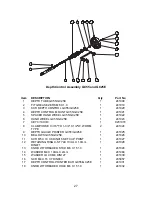

Summary of Contents for GC25E

Page 39: ...39 NOTES...