OLP 05/00

LUBRICATION

Break-in oil

1. Use one of the following during the first 100 hours

of operation:

a. John Deere Engine Break-In Oil

b. API Service CE oil

c. ACEA Specification E1

2.

Do not use

John Deere PLUS-50 oil or engine oils

meeting API CG4, API CF4, ACEA E3, or ACEA

E2 performance levels during the first 100 hours of

operation of a new or rebuilt engine. These oils will

not allow the engine to break-in properly.

Lubrication - General

1. Use only clean, high quality lubricants stored in

clean containers in a protected area.

2. These oils are acceptable after the first 100 hours:

a. API Service CC/CD single viscosity oils.

b. API Service CD/CG-4/CF-4 multi-viscosity oils.

c. ACEA Specification E3/E2 multi-viscosity oils.

3. Use the proper weight oil for your average operation

temperature.

4. Some increase in oil consumption may be expected

when SAE 5W and SAE 5-20W oils are used. Check

oil level frequently.

5. Never put additives or flushing oil in crankcase.

SP1. CHECK ENGINE OIL LEVEL

1. Check the oil level in the crankcase, with the oil

dipstick, daily.

2. The oil level must be between the “Waffled area” and

the “oo”. Never allow the level to go below the “oo”.

3. Always add the same viscosity of oil as is already in

the crankcase.

SP2. OIL CHANGES

1. Using the oil recommended above, change the

engine oil and filter after the first 50 hours of

operation, the first 100 hours and every 200 hours

thereafter.

Marine Generator Sets:

a. Remove plug from outlet in base frame. Screw in

owner-supplied drain hose.

b. Open valve at oil pan outlet. After oil has been

drained into suitable container, close valve, remove

drain hose and replace plug in base frame outlet.

c. Refill engine with recommended oil.

4. Engine Lube Oil Capacity:

SP3. CHANGING OIL FILTER

1. Change the lube oil filter every 200 hours.

2. Use a filter wrench to remove old filter. Dispose of

filter in approved manner.

3. Make sure the gasket from the old filter is removed

and discarded.

4. Lubricate the rubber gasket on the new filter and screw

it on nipple until gasket meet the sealing surface.

5.

Using hands only, no wrench, tighten filter one-half turn

farther. Overtightening can do damage to filter housing.

6. Fill engine with recommended oil. Start engine and

check for leakage. Stop engine and check oil level.

Add additional oil if necessary.

SP4. AIR Cleaner

1. Inspect air cleaner every 100 hours. Replace filter

every 600 hours, or yearly, whichever comes first.

2. Clean the rubber tube at the cleaner. Loosen the hose

clamp and the attaching strip for the cleaner.

3. Make sure the rubber tube is in good condition and

that new filter is absolutely clean and installed prop

-

erly.

4. Start the engine and check for leaks.

NOTE:

Make absolutely sure no impurities enter

the engine while changing the element. Do not

run the engine with the air cleaner removed.

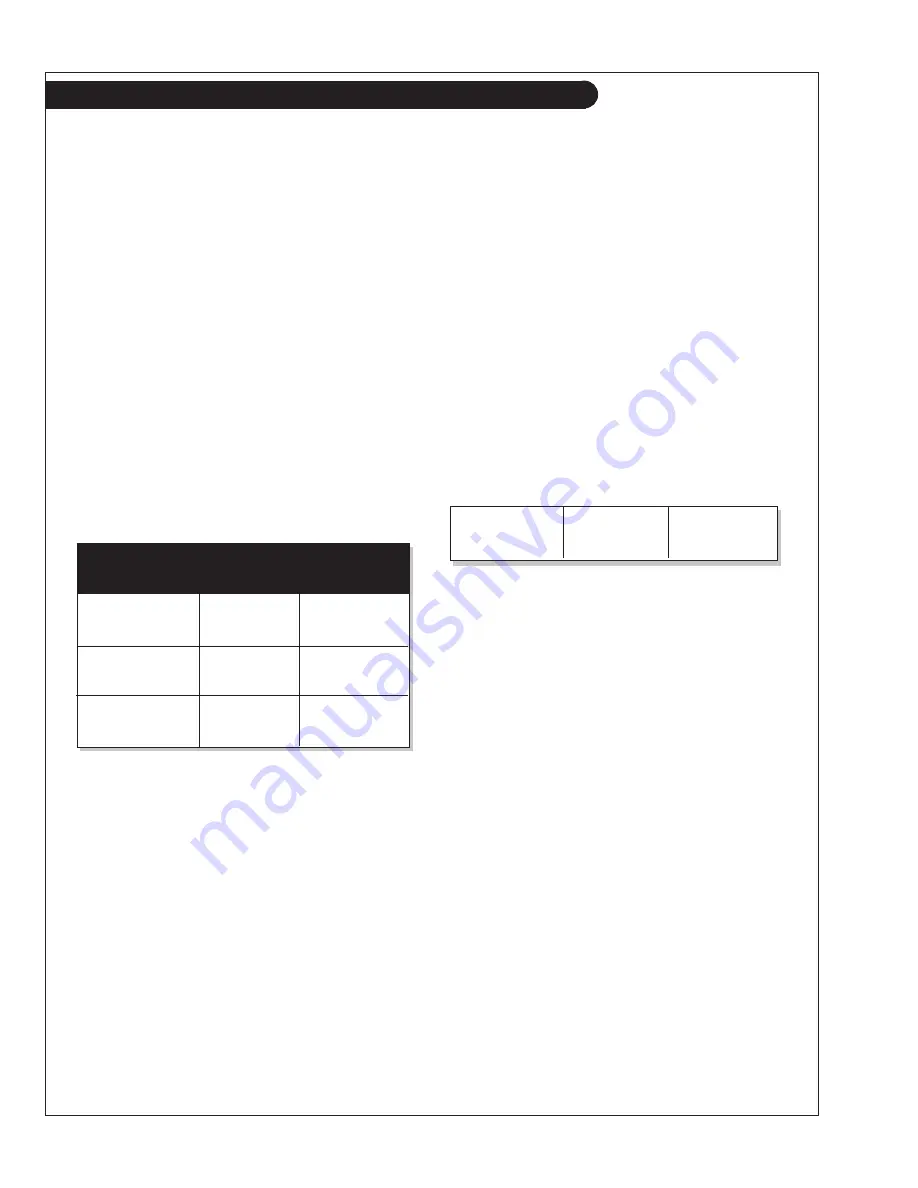

Air

Single Multi

Temperature Viscosity

Viscosity

Above 32°F

(0°C)

SAE-30W SAE15-40W

-10°F to 32°F

(-23°C to 0°C)

SAE-10W SAE10-30W

Below -10°F

(-23°C)

SAE-5W SAE5-20W

445 Series

14 qts.

13.2 liters

668 Series

18 qts.

17.0 liters

10

Servicing

2. During intermittent cold weather operation, change oil

every 100 hours or six weeks, whichever comes first.

3. Change oil at any seasonal change in temperature when

a new viscosity of oil is required.

Propulsion Engines

w/Optional Drain Pump:

a. Remove dipstick.

b. Unscrew dipstick tube and insert the hand pump to

the bottom of the oil pan. Drain by pumping.

c. Replace dipstick tube and dipstick.

d Refill engine with recommended oil.

Summary of Contents for OLP LP445

Page 29: ...OLP 05 00 27 Wiring Diagrams DC Engine Wiring Diagram 12 Volt Lugger LP668 Drawing C 4363B...

Page 30: ...OLP 05 00 28 DC Engine Wiring Diagram 12 Volt Lugger LP445 Drawing C 4364A Wiring Diagrams...

Page 31: ...OLP 05 00 Wiring Diagrams 29 DC Engine Wiring Diagram 24 Volt Lugger LP668 Drawing C 4370A...

Page 32: ...OLP 05 00 Wiring Diagrams 30 DC Engine Wiring Diagram 24 Volt Lugger LP445 Drawing C 4371...

Page 34: ...OLP 05 00 32 Notes...

Page 35: ......