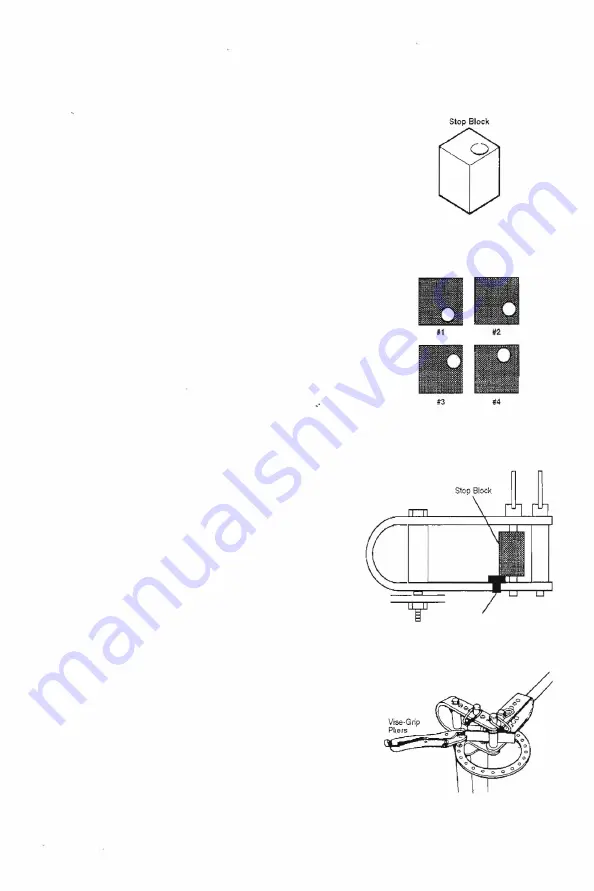

Operation: Using the Stop Block

IMPORTANT: R

ea

d

page

5

before

you p

r

oce

ed to

t

h

i

s section.

Purpose of the Stop Block

The stop

block prevents the material from rotating while a forming die in the

ha

n

dl

e

bends

the material around either the center pin or

a

n

oth

er

die

that

has

been installed on the center pin.

When

you are

b

en

d

i

n

g material,

the

stop block will

be

located (using a hitch

pin) at one of the five large holes in

the m

i

dd

l

e of

the

ring

a

s

s

em

b

l

y

'

s loop.

(The large hole at the open end of the loop is

for the center

p

i

n

.

)

You

will

have

to

detemnine by trial which hole you will

use,

d

epe

nd

i

n

g

on the thick·

ness of

the

material being bent. the size

of

the ce

n

ter

-

p

i

n die, and the orien

talion of

the s

t

op

b

l

ock

.

Positioning the Stop Block

The

stop block can be placed in several orientations by rotating

it

on

the

hinge pin or by turning it upside down and rotating it on the pin. However

only four of the possible orientations are

used

when bending. Throughout

this manual, those four o

r

i

e

nta

tion

s

are identdied

by

a

number (

r

efe

r

to the

illustration

at righ

t

)

.

CAUTION: Always

posrtion

the

stop block

of/-center

to the

r

ight

no

m

a

tt

e

r

which face is used against the m

at

e

r

ia

L If

positioned

off·

center to the left, the block

will

tu

r

n and

the material will

slip in

t

h

e

B

e

nd

er

.

To position

t

h

e stop block (that

is,

to select

the proper or

i

en

ta

ti

on

and

t

h

e

proper hole

in

the loop):

1.

Connect

the

handle

to the center

pin of the

loop, with the appropriate

die

i

n

s

t

a

ll

ed

on the center pi

n.

2.

I

ns

ta

ll the

appropriate die at the

a

pprop

r

i

at

e

hole in the handle.

3.

Insert

a

piece

of the material to be formed. With the

handle all

t

h

e way

back (counterclockwise),

i

n

st

a

ll

the stop block - in

t

h

e

orientation that

places it as close to the center pin as possible.

IMPORTANT: Atways

use the loop hole that places the slop block

as

close to the center

pin

or die as possible, while l

eavi

n

g space for the

material to be

inserted.

If there is too much space between

the s

t

op block

and

the center pin

or

d

i

e

,

turn the b

l

oc

k

to a different

orientation or move the block o

n

e

h

o

l

e

c

los

e

r

t

o

t

h

e ce

n

t

e

r

.

Positioning the Block Support

The block

s

u

ppo

rt

must be located

under

the stop block

as

shown,

to keep

the

block

c

en

t

e

r

e

d

vertically in the

l

o

o

p

.

Install the support

in

the app

r

opr

iat

e

l

oop hole where it

will

support the stop

block

but not interfere with inserting the

hitch pin

all the

way t

h

r

o

u

gh

the

block hole and the lower hole

in the loop.

Clamping

If the slop block is positioned correctly, the material wiil normally not have to

be clamped

in

the Bender. However,

when

you are making special bends or

need precise dimensions, it

is

helpful to

clamp

the material against the

s

t

op

block

using a vise-grip pliers

as

shown at rig

h

t

.

6

Stop Block Orientations

Positioning

the Block Support

Block Support

Clamping the Material