17

TROUBLESHOOTING

If the unit does not operate properly in the cooling

mode, check the following:

• The thermostat is operating properly.

• Electrical power to the unit is turned on.

• All safety switches are closed.

• The service doors are in place.

• Transformer circuit breaker is reset.

If the unit does not operate properly in the heating

mode, check the following:

• The thermostat is operating properly.

• Electrical power to the unit is turned on.

• All safety switches are closed.

• The gas is on and shut-off valve is open.

• The service doors are in place.

• The fl ame roll-out control is closed.

• Refer to the diagnostic codes in Tables 1 or 2, or the

wiring diagrams (Figures 15 - 19, pages 37 - 41).

• Transformer circuit breaker is reset.

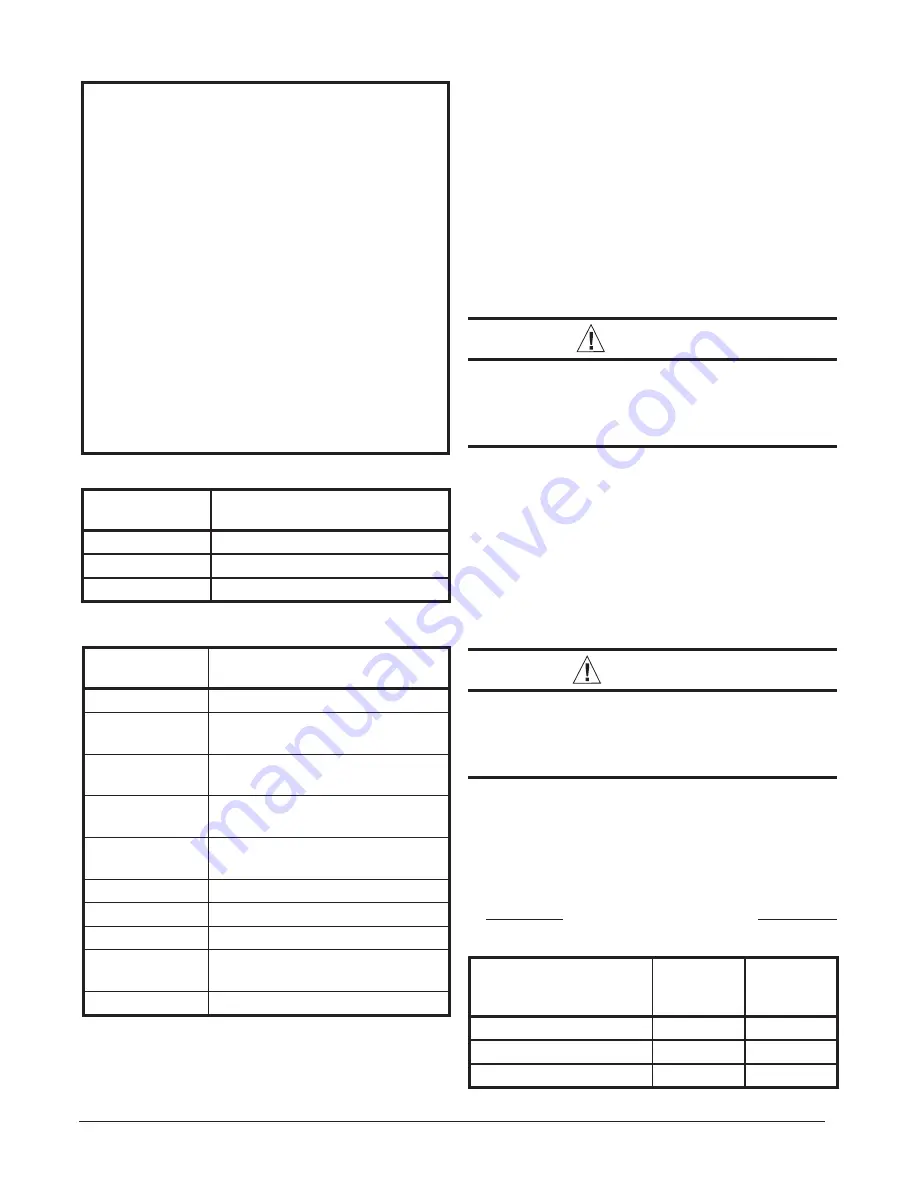

Table 1. Diagnostic Codes For 7 1/2 & 10 Ton Units

STATUS LIGHT

(RED)

FAULT

CONDITION

Continuous ON

Internal Control Failure

2 Flashes

Flame Sense Problem

3 Flashes

Ignition Lockout

STATUS LIGHT

(Red LED)

FAULT

CONDITION

Continuous ON

Operation Normal

2 Flashes

Pressure/centrifugal switch open

with inducer on

3 Flashes

Pressure/centrifugal switch closed

with inducer off

4 Flashes

Lockout from too many

failed ignition tries

5 Flashes

Lockout from too many

fl ame losses

6 Flashes

High temperature switch open

7 Flashes

Rollout switch open

8 Flashes

Flame present with gas off

9 Flashes

Exceeded max limit trips (5)

in one call for heat

10 Flashes

Gas valve fault

Table 2. Diagnostic Codes For 6 Ton Units

UNIT MAINTENANCE

NOTE:

These maintenance instructions are primarily

intended to assist qualifi ed technicians experienced in the

proper maintenance and operation of this appliance

.

To achieve optimum performance from the air conditioner

and minimize equipment failure, it is recommended

that periodic maintenance be performed on this unit.

The ability to properly perform maintenance on this

equipment requires certain mechanical skills and tools.

Please consult your dealer for maintenance information

and availability of maintenance contracts.

CAUTION:

Use care when removing parts from this unit.

Personal injury can result from sharp metal

edges present in all equipment of sheet metal

construction.

At a minimum, routine maintenance should include the

following items:

Condensate Drain and Outdoor Coil

Inspect the condensate drain and outdoor coil at the

beginning of each cooling season. Remove any debris.

Clean the outdoor coil and hail guard louvers (optional)

as necessary using a mild detergent and water. Rinse

thoroughly with water.

Air Filters

WARNING:

Never operate the unit without fi lters in place. Dust

and lint in the return air can build up on internal

components, resulting in loss of effi ciency,

equipment damage, and possible fi re.

It is recommended that the air fi lters be inspected and

cleaned or replaced every three to four weeks using fi lters

of like size and kind. Table 3 lists the correct fi lter sizes

and quantities for each unit.

IMPORTANT NOTE: R6GP units are equipped with 2”

pleated disposable fi lters. Filter rack is adjustable for

1” permanent type fi lters. DO NOT use 1” disposable

fi lters.

UNIT

FACTORY

FILTER

SIZE

QTY

R6GP-072*-(100/166)C

16x20x2

4

R6GP-090*-200C

16x20x2

4

R6GP-120*-235C

16x25x2

4

Table 3. Filter Sizes and Quantities