13

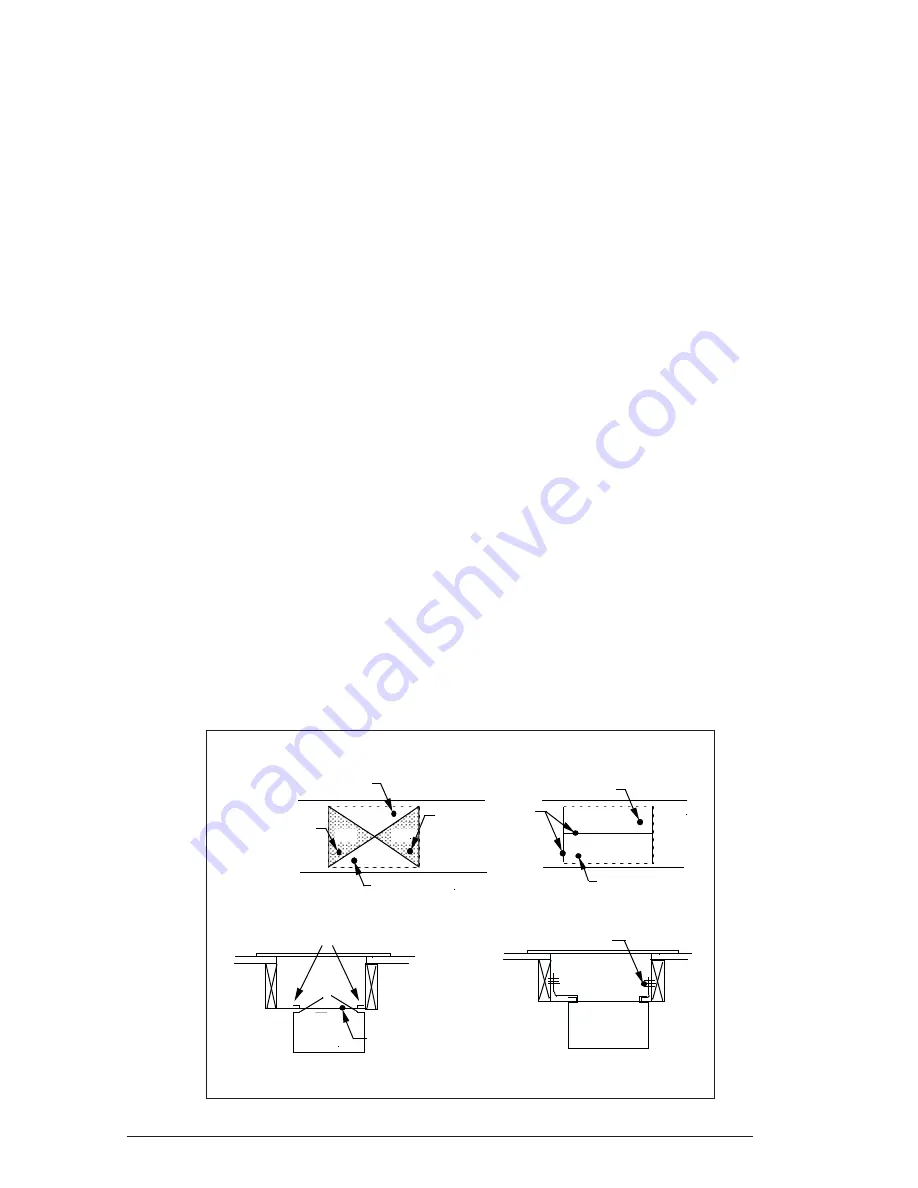

Staple Folded Duct

Flap (typ) to side of Duct

Connector

Duct

STEP 4.

STEP 1.

"A"

"A"

"B"

"B"

Cut- Out

Area"A"

Cut- Out

Area "A"

Fold Back Flap "B"

Fold Back Flap "B"

Top of Duct

"A"

"A"

STEP 2.

"B"

"B"

Fold Back Flap"B"

Cut

Lines

Duct

Fold Back Flap"B"

STEP 3.

Bend Duct Connector Tabs Up

and Over- (along length of duct)

Duct

Flap "B"

Duct

Figure 18.

INSTALL FURNACE

a. Remove furnace outer door(s) and bottom

fuel line knockout.

b. Place furnace onto duct connector and center

with fl oor opening.

c. Slide onto mounting plate. (Bottom rear slots

on furnace should engage with mounting plate

tabs.)

d. Secure front with one (1) fastener at each

corner (See Figure 19 or 20).

NOTE:

Additional fasteners may be used at rear,

sides or through door frame, as desired, to secure

furnace to closet or alcove framing.

INSTALL ROOF JACK

Apply caulking compound on underside of roof

fl ashing to form a continuous strip at least 3/8”

wide (see Figure 21) around the underside of

the perimeter of the fl ashing. Connect Roof Jack

Assembly to the furnace. Insert telescoping

Roof Jack Assembly through the opening cut

on the roof. Connect fl ue pipe to fl ue collar of

furnace. Connect combustion air pipe to furnace

collar with sheet metal screw (See Figure 22).

It is recommended that the connection of the

combustion air pipe to the furnace be made

before the fl ashing is secured to the roof to

maintain alignment of roof jack and furnace

connections.

NOTE:

For replacement furnaces, be sure the

inner fl ue pipe connects over the furnace vent

collar.

DO NOT use a smaller diameter inner

fl ue pipe which could slide inside the furnace

vent collar and restrict the fl ow of furnace

fl ue products.

Attach Roof Flashing: If necessary, shift roof

fl ashing slightly in the roof opening so that as-

sembly is in good alignment with furnace. Press

down fi rmly over caulking on roof fl ashing to make

the seal with roof water tight. Secure fl ashing with

appropriate fasteners. As an added protection

against leaks, coat the fl ashing plate and fasten-

ers with approved roofi ng compound.

If fl ashing mounted on 12 degree angle is used

it may be necessary to adjust the angle to match

the roof pitch; (1/12 - 4/12 maximum).

12. INSTALLATION OF TRANSIT-

MODE VENTING SYSTEM

MANUFACTURED HOME FACTORY

a. Furnace to be installed per furnace installation

manual.

b. Roof Jack to be selected from Table 5 of these

instructions.

c. Roof Jack (less upper Roof Jack crown), with

weather cap to be installed as described under

Install Roof Jack.

d. Upper Roof Jack crown to be stored in a

prominent location inside manufactured home

until on-site installation.

e.

The four warning tags supplied must be

installed as follows:

• To weather cap

• To fuel line connection point (Gas) or

furnace burner (Oil)