26

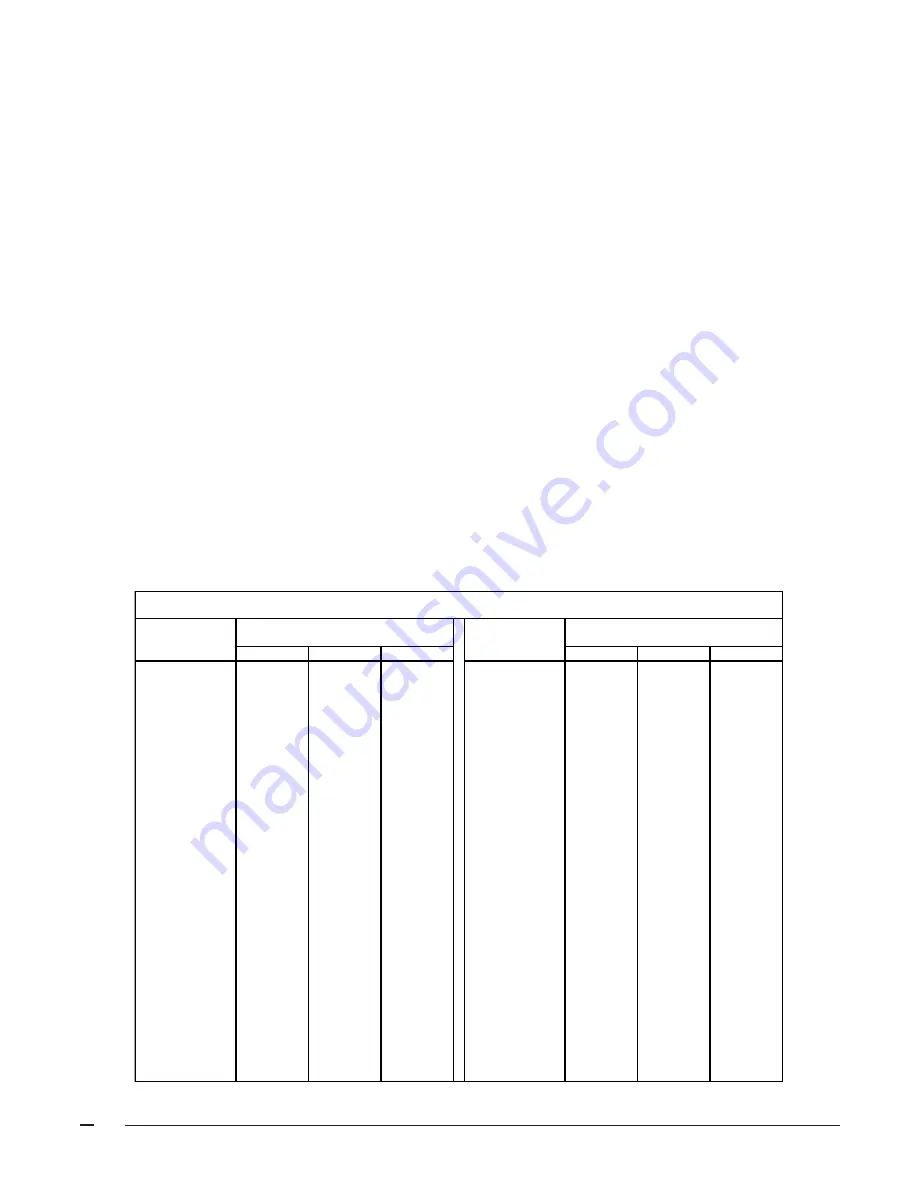

Table 11. Gas Flow Rate

TIME FOR

TIME FOR

ONE REVOLUTION

ONE REVOLUTION

(SECONDS)

1

5

10

(SECONDS)

1

5

10

10

360

1800

3600

66

55

273

545

12

300

1500

3000

68

53

265

529

14

257

1286

2571

70

51

257

514

16

225

1125

2250

72

50

250

500

18

200

1000

2000

74

49

243

486

20

180

900

1800

76

47

237

474

22

164

818

1636

78

46

231

462

24

150

750

1500

80

45

225

450

26

138

692

1385

82

44

220

439

28

129

643

1286

84

43

214

429

30

120

600

1200

86

42

209

419

32

113

563

1125

88

41

205

409

34

106

529

1059

90

40

200

400

36

100

500

1000

92

39

196

391

38

95

474

947

94

38

191

383

40

90

450

900

96

38

188

375

42

86

429

857

98

37

184

367

44

82

409

818

100

36

180

360

46

78

391

783

102

35

176

353

48

75

375

750

104

35

173

346

50

72

360

720

106

34

170

340

52

69

346

692

108

33

167

333

54

67

333

667

110

33

164

327

56

64

321

643

112

32

161

321

58

62

310

621

114

32

158

316

60

60

300

600

116

31

155

310

62

58

290

581

118

31

153

305

64

56

281

563

120

30

150

300

GAS FLOW RATE (CUBIC FEET PER HOUR)

CUBIC FEET PER REVOLUTION OF

METER

CUBIC FEET PER REVOLUTION OF

METER

Selecting The Cooling/Heat Pump Airflow

In order to select the appropriate airflow for AC and HP

operation the nominal system capacity must be known.

The nominal system capacity is ALWAYS the nominal

capacity of the outdoor unit. In some cases the nominal

system capacity is not the same as the nominal capacity

of the indoor coil.

The cooling/heat pump airflow is selected by setting

switches 1 through 4 on the motor control board located in

the blower control panel. All airflows for other modes of

operation (except gas heat) are determined by this setting.

Table 1 shows the airflow values versus the airflow selector

switch settings, and the range of airflow settings recom-

mended for each nominal system capacity.

NOTE: The CFM values listed on Table 2 are not

dependent on duct static pressure. The motor auto-

matically compensates for changes in duct static pres-

sure (within the limits of the motor).

For Two Stage Cooling:

The furnace is supplied with the yellow "Y1" and blue "Y2"

connections attached to the control board. When installing

this furnace with a two stage condensing unit, remove the

blue "Y2" wire from the control board and connect to the

thermostat. Connect a field supplied wire from the yellow

"Y1" to the thermostat and the condensing unit, and

another wire from "Y2" on the thermostat to "Y2" on the

condenser. (See Figure 23).

For maximum capacity and energy efficiency, generally, a

selection at or near the top of the CFM range for that

nominal capacity is best. For maximum dehumidification,

select an airflow near the middle or bottom of the CFM

range for that nominal capacity.

IMPORTANT NOTE: When installing a 2-stage heat

pump with a fossil fuel kit, the transformer in the

furnace MUST be upgraded to one with a 60VA rating

(Part No. 904077)

.

NOTE: If coil icing is observed, the cooling/heat pump

airflow selected may be too low. Double-check to be

sure the setting selected is within the range shown in

Table 1. Also check to be sure the system is properly

charged (see outdoor unit installation instructions). If

icing continues to occur, raise the selected airflow one

or two steps.

Verifying and Adjusting Temperature Rise

Verify the temperature rise through the furnace is within the

range specified on the furnace rating plate. Temperature

Summary of Contents for 060C-12

Page 2: ......