Trilogy

r

Air-Assisted Airless LT Manual Spray Gun

12

Part 1601052-03

E

2016 Nordson Corporation

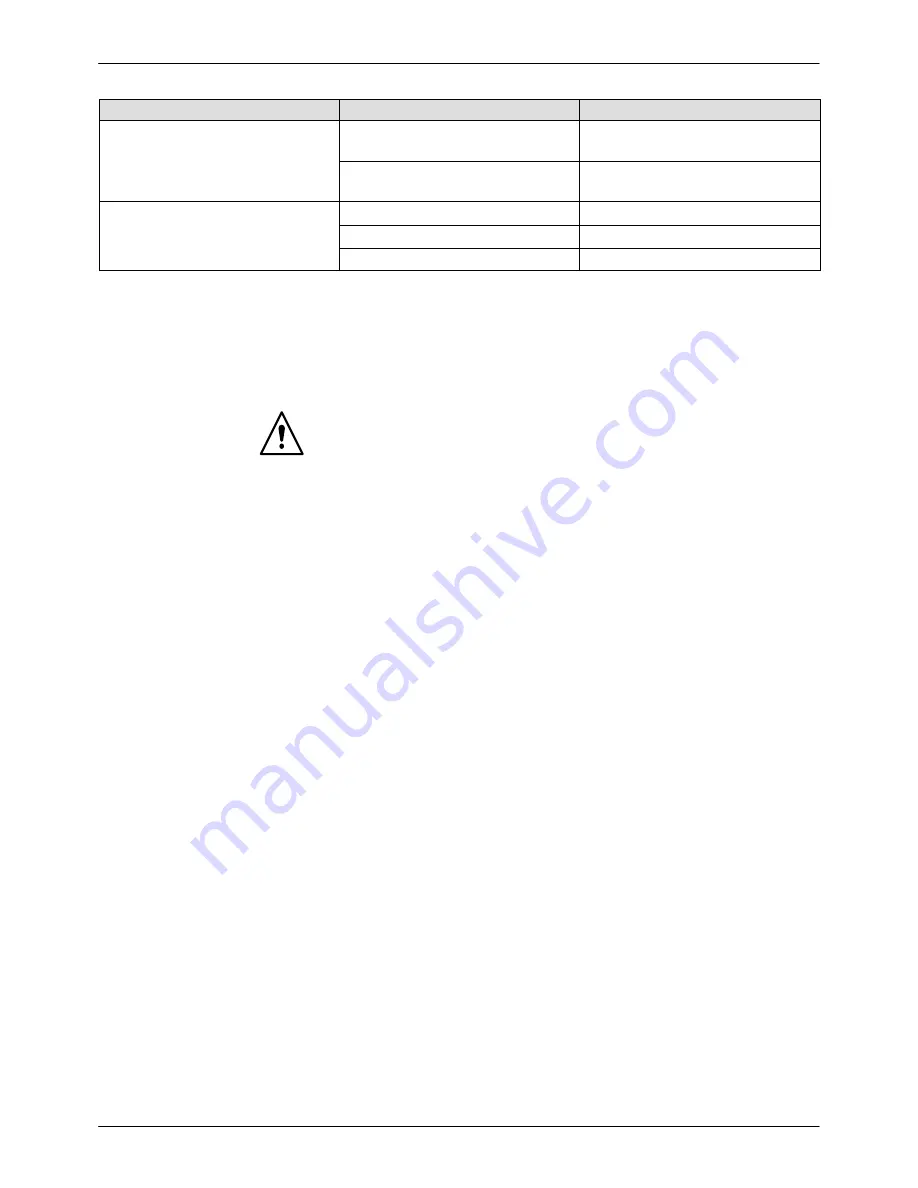

Corrective Action

Possible Cause

Problem

4. Spray gun leaks paint from

packing gland

Needle cup seals worn.

Replace cup seals and O-rings

(33, 34).

Packing gland not tightened

enough.

Tighten packing gland (29).

5. Spray gun is leaking air

Air valve spring weak

Replace spring (36).

Air valve seal worn

Replace seal (39).

Air valve defective

Replace valve (37).

Repair

Preparation

WARNING:

High Pressure Hazard! Always stop the pump and relieve

system fluid pressure before attempting to repair the spray gun. Failure to

observe this warning could result in severe personal injury or even death.

1. Supply solvent to the delivery pump and flush the spray gun.

2. Stop the pump and relieve the fluid pressure. Disconnect the fluid hose.

3. Shut off the air supply and relieve the air pressure. Disconnect the air

hose.

Air Cap and Nozzle Replacement

1. See Figure 4. Remove the air cap retainer, air cap, and nozzle (1, 2, 3).

2. Push the nozzle (3) out of the air cap (2).

3. Remove the seal (3a) from the nozzle.

4. Immerse the nozzle in solvent or waterborne cleaning solution. If

necessary, use an ultrasonic cleaner to clean the nozzle. Use only tools

designed for nozzle cleaning to clean the nozzle orifice. Contact your

Nordson representative for nozzle cleaning kits.

5. Install the seal on the cleaned nozzle.

6. Install a new or clean nozzle in the air cap.

7. Install the air cap on the gun. Adjust the air cap orientation and hold it

while tightening the air cap retainer.

Needle Replacement

1. See Figure 4. Unscrew and remove the spring cap, spring, and washers

(23, 24, 25, 26).

2. Loosen the needle packing gland (29).

3. Pull the needle assembly (27, 28, 32) out of the gun.

4. Install a new needle assembly in the gun, then screw the spring cap

back into the gun and tighten securely.

5. Tighten the needle packing gland. If paint leaks from the packing gland

when the gun is put back into service, tighten the packing gland further.