12

GB

We recommend seasoned hardwood with a maximum

moisture content of 20%.

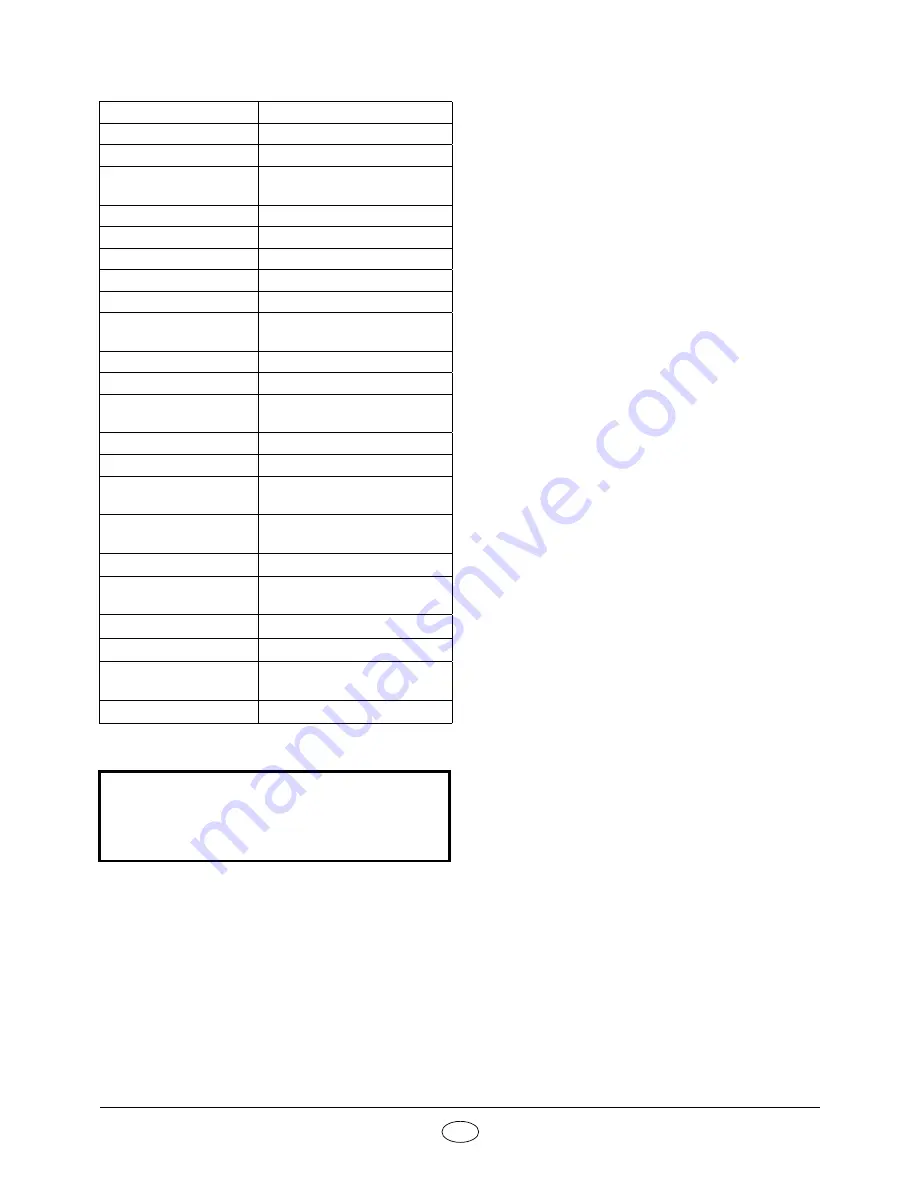

Surround

Ronda

Insert

NI-26

Material insert

Steel/Cast iron

Surface treatment

door / doorframe

Heat resistant varnish

Fuel

Wood logs, 30 cm

Nominal output

5 kW

Efficiency

79,3%

CO % @ 13% O

2

0,07

Draught system

Air vent control

Combustion system

Secondary combustion

(clean burning)

Heating area

60-120 m²

Flue outlet

Top

Flue

Inner Ø 150 mm

(NB! In UK outer Ø)

Weight of insert

93 kg

Weight of surround

239 kg

Area of convection

air vent under insert

400 cm²

Area of convection

air vent over insert

500 cm²

Flue gas temperature

313 °C

Air supply

requirements

(m³/h)

11

Fuel charge

1,4 kg

Refueling interval

56 min

Opening of the air

vent control

50%

Operation

Intermittent*

* Intermittent combustion refers to normal use of a fireplace,

i.e. new wood is inserted when the previous load has burned

down to ember.

Warning: If the requirements for ventilation are

NOT complied with, the heating circulation effect

will be considerably reduced and

overheating can occur.

This can in a worst case scenario cause a fire.

4. Distance to Combustible Material

Firewall

Ensure that the safety distances are respected

(FIG 1).

When connecting a steel chimney to the top outlet use

the security distances required from the manufacturer.

5. Assembly

Assembly instructions for the insert

(FIG 2 - FIG 12)

The following tools are necessary:

•

5 mm Allen key

•

13 mm spanner/wrench

•

Caulking gun (for the stove cement)

1.

Ensure that all the loose parts are included (FIG 2):

A.

Insert with door and heat shield

B.

4 legs with adjusting bolts and lock nuts

C.

4 fastening bolts with disks for the legs

D.

Handle for ash grate and ashtray

E.

Glove

F.

Assembly instructions

G.

Warranty card

2.

Carefully lay the insert on its back. Ensure that the

transportation padding is put inside the insert before

turning it over, so that the insulating plates in the

burn chamber do not fall down and break. Please

note that the insulating plates may release coloured

dust when touched. Avoid touching the cast iron with

dust on your fingers. In case of dust on any cast iron

part, the glove included is well suited to brush it off.

Start with assembling the legs (FIG 3) as follows:

•

Fasten the screws on to the insert with a 13 mm

spanner/wrench. The legs are placed as shown (the

opening in the legs should face outwards).

•

Use the adjusting bolts (FIG 4) and adjust the legs

to the desired height (X) before returning the insert

to an upright position

(do not tilt the insert).

The

height depends on the surround.

Regulation of leg height (X) for NI-26:

From

: 20 mm

To

: 160 mm.

•

Flue outlet

NI-26 is delivered standard with a top flue outlet collar.

In order to change to a posterior mounted flue outlet:

FIG 5A:

Remove the perforated decoration lid in the

back with a hammer, or saw it out with a hacksaw

FIG 5B:

Unscrew the sheet steel lid.

FIG 6:

Unscrew the flue outlet collar with a 5 mm Allen key.

FIG 7:

Fasten the sheet steel lid on the top flue outlet.

FIG 8:

Fasten the collar on the posterior flue outlet.

Connection of the Flue

Please be aware when connecting the 150 mm flue to

the smoke outlet that the flue is placed outside the flue

outlet collar. Use stove cement in the joints.

* The approximate centre height of the hole for the

flue is marked in the dimensioned drawing

. Consider

possible inclination of the flue prior to perforating the

chimney.

Distortions in floors and walls may influence

the height.

Dry stack the fireplace for accurate height

and positioning of the flue/chimney connection

. If

Summary of Contents for CC-RIO00-100 Ronda

Page 38: ...38 2000 600 641 1240 336 Ronda mm Ronda air 625 135 140 ...

Page 41: ...41 X FIG 3 FIG 4 ...

Page 42: ...42 FIG 5A FIG 6 FIG 7 FIG 5B FIG 8 FIG 9A FIG 9B ...

Page 43: ...43 FIG 10 FIG 11A FIG 11B FIG 12 G H F I ...

Page 45: ...45 FIG 14 FIG 15 FIG 13 124 mm 2 1 3 FIG 16 2 165 FIG 15b ...

Page 46: ...46 FIG 18 FIG 19 FIG 20 5 6 2 mm 641 mm 4 4 FIG 17 ...