NORDAC SK 1000E Hardware description

BU1100 GB

23

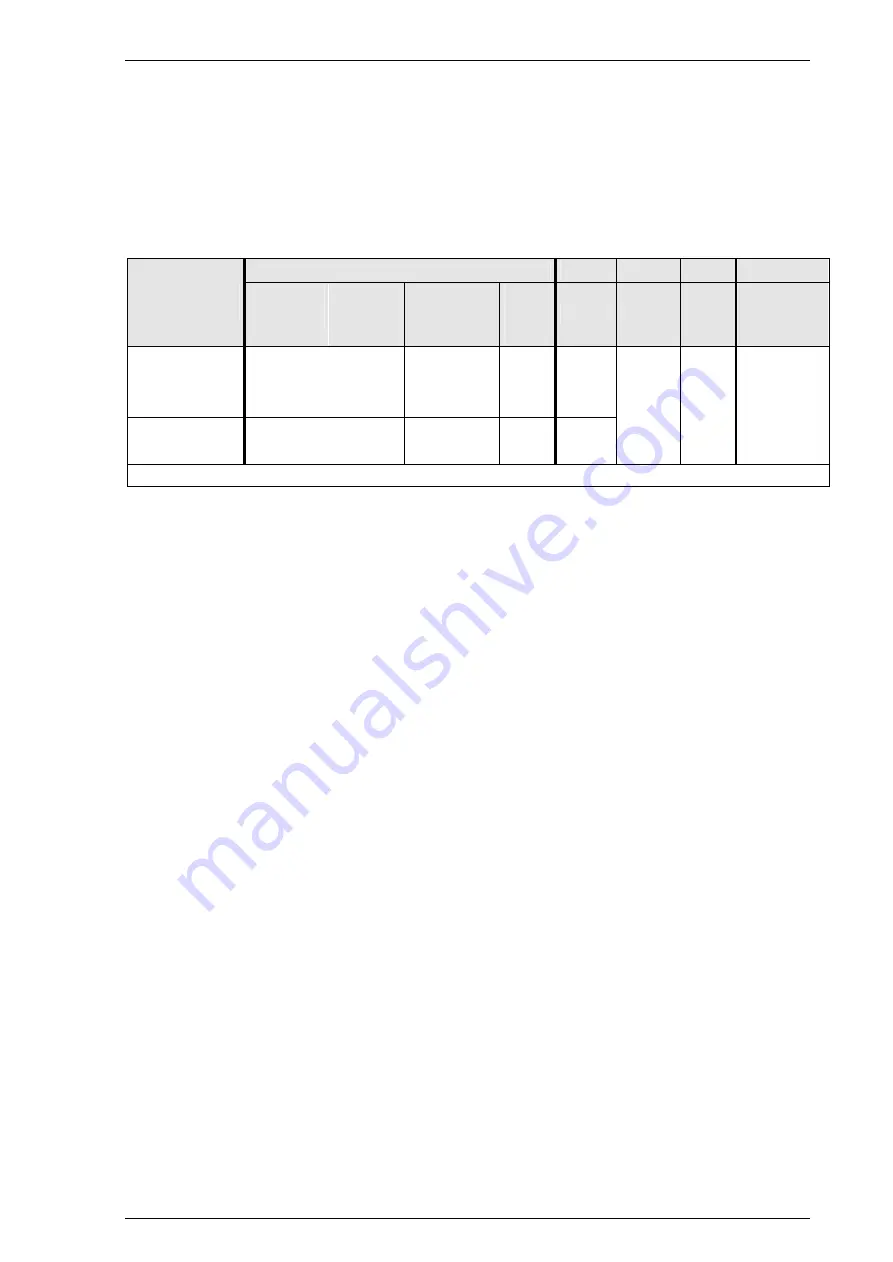

3.3.2 Brake resistor (Optional)

During dynamic braking of the motor, electrical energy is returned to the servo controller. To prevent

over-voltage cut-off , the integrated brake chopper, can convert the recovered energy into heat by

connecting an external brake resistor (optional). The capacity of the brake resistor must be matched to

the relevant application. The customer can select from a wide range of capacities. Generally, the

following assignments apply to most application cases, sizes are calculated from the mass being

braked and the cycle times:

Braking resistor

Length

Width

Depth Connection

Servo controller

type SK 1000E-

Type

SK BR1-

Resistor

Ohm

Continuous

consumption

W

Pulse

power

KW

mm²

101-340-A

201-340-A

301-340-A

200/100

200/300

100/400

200

200

100

100

300

400

1.8

3.0

3.6

281

401-340-A

501-340-A

60/600

60/600

60

60

600

600

6.0

6.0

331

121

48

0.75

200 long

All dimensions in mm, pulse power is dependent on application, max. switch on duration 5% / 120 s

3.3.3 Cable set

General:

Drag-resistant and oil-resistant with Cu shield braid

Cable and plugs UL/CSA authorised

Kink protection and strain relief

Working temperature up to 65 degrees Celsius

DESINA colours: Power cable orange,

resolver and encoder cables green,

Bus cables: CAN, RS485, RS232 and connection cables violet

Cable marking:

UL, CSA

Protected label 30 mm from each end (plug or shield end):

Getriebebau NORD

Part No: e.g. XXXXXXXXX (different for each length)

Type, e.g. resolver cable

Length, e.g. 10m

Cable lengths:

Ready to use cables 3m, 10m, 15m and 20m from the factory

Ready to use cables can be ordered in any length.

Orientation of all Sub-D plug housings:

On the servo controller (view from front, when mounted in control cabinet):

Cables must hang down with angled hoods

Longer side (i.e. PIN 1) is always left and shorter side is always right!

3.3.4 CAN connecting terminal screw connection

Terminal screw connectors are recommended for connection to the CAN Open socket:

1. Bus connector, CAN bus, Sangel, Order No.: 101-690-0BA11

2. Erbic CAN bus node, horizontal, with programming connection, ERNI, article No.: 103662

3. T-adapter for CAN bus, PEAK-System Technik, No.: IPEK- 003003,

with PCAN cable without terminating resistor, PEAK-System Technik, No.: IPEK- 003000

4. Bus connector, CAN, without connection socket, Helmholz, Order No.: 700-690-0BA11