OPERATION

Nobles

Tuff Scrub

3300 (06–0

17

QUARTERLY MAINTENANCE

(Every 250 Hours of Use)

1.

Check drive transaxle, vacuum and brush motors

for carbon brush wear, replace brushes when worn

to a length of 10 mm (0.38 in) or less.

Contact an Authorized Service Center for motor

maintenance.

2.

Check steering chain tension (See STEERING

CHAIN MAINTENANCE).

BATTERY MAINTENANCE

WARNING: Batteries emit hydrogen gas.

Explosion or fire can result. Keep sparks and

open flame away.

FOR SAFETY: When servicing machine, wear

hand and eye protection when handling batteries

and battery cables. Avoid contact with battery

acid.

1.

Always follow proper charging instructions (See

CHARGING BATTERIES).

2.

After charging, check fluid level (A). Fluid level

should be within 3 mm (0.13 in) of full level

indicator. Add distilled water if needed. DO NOT

OVERFILL. Overfilled batteries will overflow

during charging due to fluid expansion (Fig. 37).

A

Figure 37

3.

Keep battery tops and terminals clean and dry.

To clean batteries:

a.

Mix a strong solution of baking soda and water

(Fig. 38).

Figure 38

b. Brush solution sparingly over battery tops,

terminal and cable connectors.

NOTE: Do not allow baking soda solution to enter

battery cells.

c.

Use wire brush to clean terminal post and

cable connections.

d.

After cleaning, apply a coating of clear battery

post protectant to terminals and cable

connections.

4.

Check for loose or worn cables. Replace if worn.

STEERING CHAIN MAINTENANCE

The steering chain tension should be checked after

the first 50 hours of operation and every 250 hours

thereafter.

FOR SAFETY: When servicing machine,

disconnect battery connections before working on

machine.

1.

To access steering chain, remove five floor panels,

13 mm wrench and Phillips head screwdriver

required (Fig. 39).

Figure 39

2.

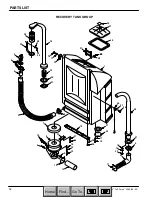

Measure amount of chain deflection at location

shown below. Proper chain deflection should be

approximately 25 mm (1.00 in) total (Fig. 40).

Idler Sprocket

Adjustment

Screw

Figure 40

Home

Find...

Go To..