OPERATION

18

s

Tuff Scrub

3300 (06–00)

3.

To adjust chain tension, loosen jam nut on the idler

sprocket adjustment screw and turn screw

clockwise to increase tension. Retighten jam nut

after adjusting (Fig. 40).

4.

Lubricate chain with a water resistant oil.

BRAKE ADJUSTMENT

If machine pulls in either direction while braking or if

machine does not stop immediately, brake adjustment

may by required.

FOR SAFETY: When servicing machine,

disconnect battery connections before working on

machine.

1.

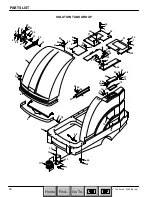

Hinge open skirts to access brakes (Fig. 41).

Figure 41

2.

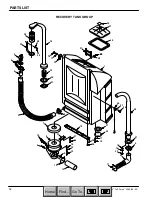

Locate hex link brake adjusters in front of each

drive wheel (Fig. 42).

Figure 42

3.

To adjust brakes, loosen jam nut and turn hex link

adjuster as described below:

RIGHT SIDE – Turn hex link adjuster clockwise to

increase or counter-clockwise to reduce brake

pressure.

LEFT SIDE – Turn hex link adjuster counter–

clockwise to increase or clockwise to reduce brake

pressure.

NOTE: Brake adjustment should be made so that

brake pads are loose; not rubbing disc. A .045” shim

should be used for proper adjustment between pad

and disc. Adjusting the brakes too tightly will create an

extra load on the drive system and cause overloading

problems.

JACKING MACHINE

Empty tanks prior to jacking. Stop machine on a flat

level surface and block machine tires before jacking

up machine.

Use designated location for jacking up machine. Use a

piece of wood to distribute machine weight (Fig. 43).

Figure 43

FOR SAFETY: When servicing machine, block

machine tires before jacking machine up.

FOR SAFETY: When servicing machine, jack

machine up at designated locations only. Block

machine up with jack stands.

Home

Find...

Go To..