JAA78851-R.3617.A

- L50 ・ AF-S DX17-55/2.8G -

(2)

Inspection of MR encoder operations

<<< EXECUTING >>>

Caution

:

If the MF ring is rotated during lens scanning, error value is shown the pulses.

Do NOT touch the MF ring during operations.

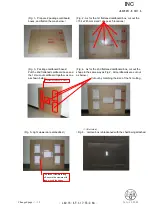

Execute inspection for the 5 positions as below.

Lens inclination

Position of index window

Horizontal

Up, right and left

Front lens group 90° upward

Front lens group 90° downward

(Lens position in inspecting)

When the inspection is ended, the inspection result appears in the next page.

INC