8 - 20

4. Go back to the MENU display.

Press

.

5. Go back to the Layout display.

Press

twice.

6. Repeat Steps 1 - 5 until the whole edge is polished evenly. *

1

7. Check the finished size after polishing.

Check each material lens for beveling and flat edging (only flat edging of Type PL4).

1) Call up the

I

45 internal data.

Press

while pressing

on the Layout display.

2) Polish the beveled lens or flat edged lens.

Leave the Size indication 0.

3) Check the finished size.

If the edged lens diameter is as follows, it is

proper.

Beveled lens: 45.00 - 45.10 mm (dia.)

Flat edged lens: 45.00 - 45.10 mm (dia.)

8. If the finished lens size is too large or too small, adjust the polishing size.

1) Call up the MENU display.

Press

.

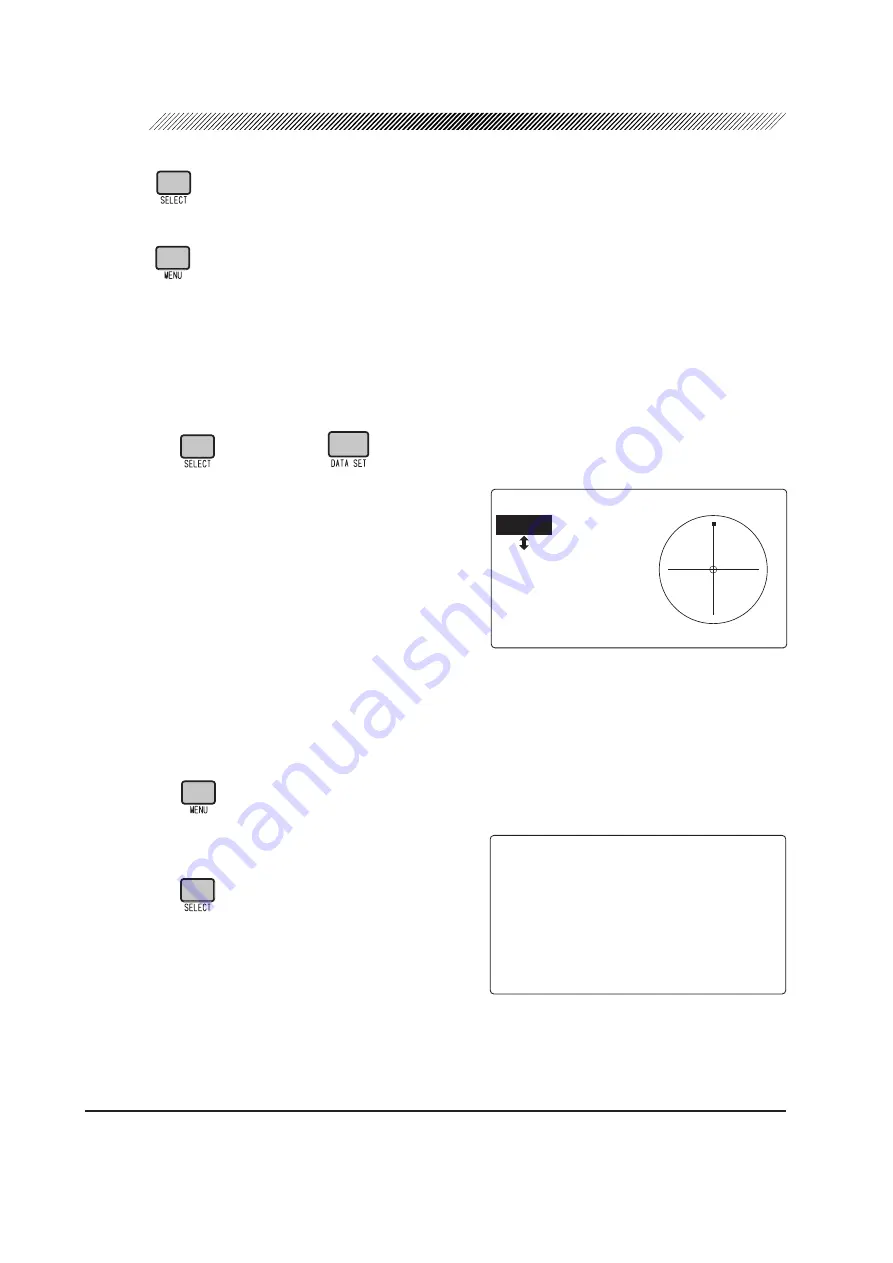

2) Call up the Size adjustment display.

Align the pointer (

o

) to “Size adjustment” and

press

.

*1 If the lens edge is not polished completely even though the constant value was adjusted, the

axis angle may be shifted, while the edge is being polished. In such a case, input the compensation

value indicated at “POL AXS const. (bevel)” or “POL AXS const. (flat)” as described in “8.11.3

Axis shift adjustment for polishing” (p. 8-23).

㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖

㧖ޓޓޓޓޓޓޓ㧿㨕㨦㨑ޓ㨍㨐㨖㨡㨟㨠㨙㨑㨚㨠ޓޓޓޓޓޓޓޓ㧖

㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖㧖

ޓޓޓޓޓޓޓޓޓޓޓ㧖㧱㨄㧵㨀ޓ㧦ޓ㧼㨞㨑㨟㨟ޓ㧿㧱㧸㧱㧯㨀ޓ

ޓψ㧲㨕㨚㨕㨟㨔ޓ㨟㨕㨦㨑㧔㧼㧸㧭㧘㨎㨑㨢㨑㨘㧕㧦ޓ㧜㧚㧜㧜㨙㨙

ޓޓ㧲㨕㨚㨕㨟㨔ޓ㨟㨕㨦㨑㧔㧼㧸㧭㧘㨒㨘㨍㨠㧕ޓ㧦ޓ㧜㧚㧜㧜㨙㨙

㧲㨕㨚㨕㨟㨔ޓ㨟㨕㨦㨑㧔㧼㧯㧘㨎㨑㨢㨑㨘㧕ޓ㧦ޓ㧜㧚㧜㧜㨙㨙

ޓ

ޓޓ㧲㨕㨚㨕㨟㨔ޓ㨟㨕㨦㨑㧔㧼㧯㧘㨒㨘㨍㨠㧕ޓޓ㧦ޓ㧜㧚㧜㧜㨙㨙

ޓ

ޓޓ㧲㨕㨚㨕㨟㨔ޓ㨟㨕㨦㨑㧔㧳㧸㧿㧘㨎㨑㨢㨑㨘㧕㧦ޓ㧜㧚㧜㧜㨙㨙

ޓޓ㧲㨕㨚㨕㨟㨔ޓ㨟㨕㨦㨑㧔㧳㧸㧿㧘㨒㨘㨍㨠㧕ޓ㧦ޓ㧜㧚㧜㧜㨙㨙

㧚ޓ

㧚ޓ

ޓ㧚

㧚ޓ

㧹㧵㧺ޓޓ㧠㧤

㧲㧼㧰㧦㧢㧞㧜㧜ޓޓޓޓޓޓޓޓ

㧼㧰

ޓ㧦㧢㧞㧜㧜ޓޓޓޓޓޓޓޓ

ޓޓޓ㧦ޓޓ㧜㧜ޓޓޓޓޓޓޓޓ

㧿㧵㨆㧦ޓ㧜㧜㧜ޓޓޓޓޓޓޓޓ

㧭㧯㨀ޓޓޓޓޓޓޓޓޓޓޓޓޓ

㧹㧱㧹㧦ޓޓޓޓޓޓޓޓޓ

㧴㧼㧸㧼㧺㨀ޓޓޓ㧼㧻㧸ޓޓ㧾

Summary of Contents for LE-9000LX

Page 1: ...PATTERNLESS EDGER Model LE 9000LX OPERATOR SMANUAL ...

Page 17: ...2 9 Top view or or ...

Page 19: ...2 11 ...

Page 145: ......