14

–

English

6

TESTING AND COMMISSIONING

These are the most important phases in automating the gate and ensuring maximum system safety.

They must be carried out by qualified and expert personnel that must decide on the tests required to verify the solutions adopted with regard to

the risks present and the compliance with laws, directives and regulations; in particular, all the requirements of the EN 13241-1 and EN 12453

standards.

The additional devices must undergo a specific test with regard to both their functions and interaction with ROBO: please refer to the instruction

manuals of the individual devices.

6.1 - Testing

The testing procedure can also be performed as a periodic check of the automation devices. Each component of the system (sensitive edges,

photocells, emergency stop, etc.) requires a specific testing phase. To do so, follow the procedures given in the instruction manuals.

Run the test as follows:

01.

Ensure that all specifications in chapter 1 “WARNINGS” have been observed in full

02.

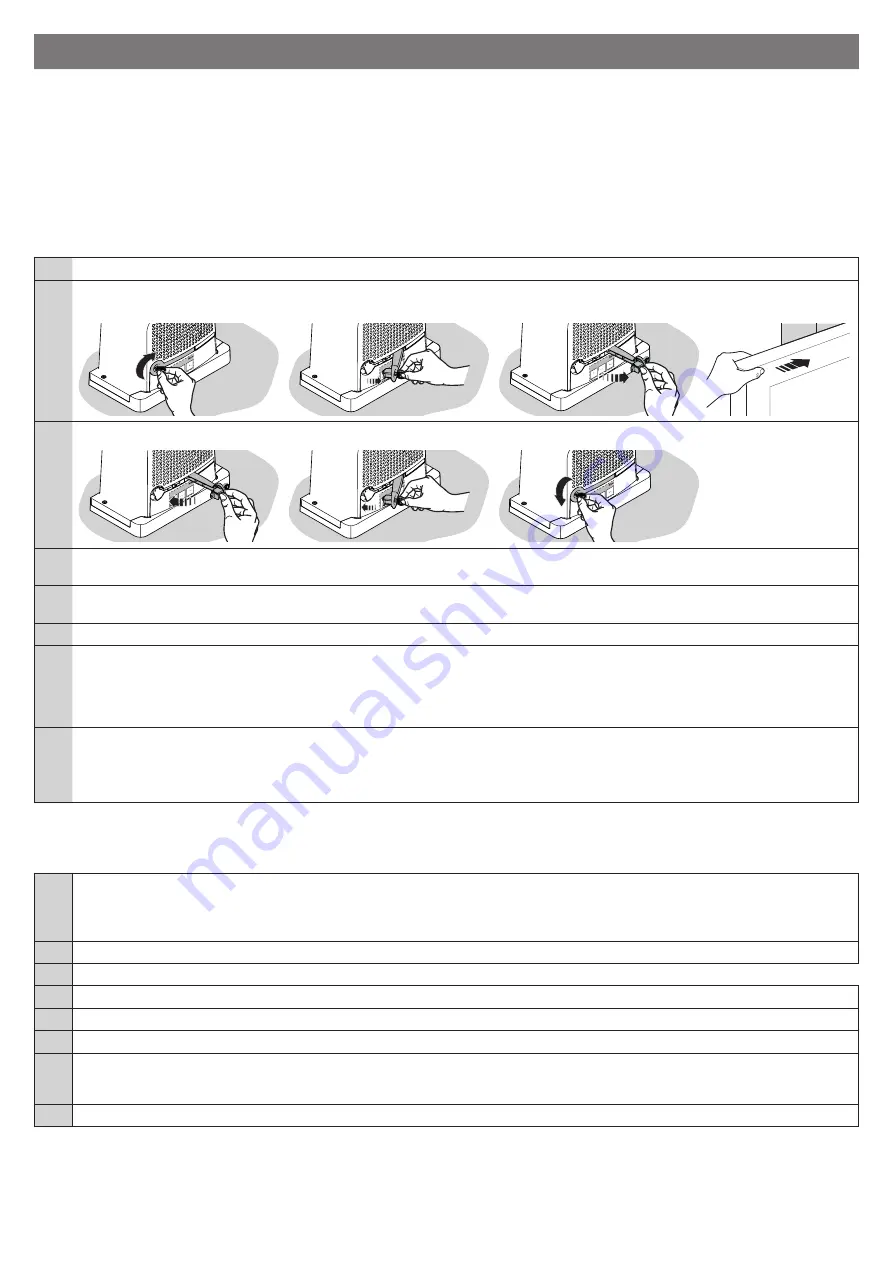

Unlock the gearmotor and verify whether it is possible to manually move the gate open and closed with a force no greater than the value

shown in “Table 1 – Essential characteristics”

Pe

r S

bloc

car

e -

Po

ur

déb

ray

er

- To u

nbl

ock

Um

zu

ent

rie

gel

n -

Pa

ra

des

bloq

uea

r

Od

blo

kow

ani

e -

Om

te

deb

lok

ker

en

-

Отп

ере

ть

2

3

1

Pe

r S

blo

cca

re

- P

our

dé

bra

yer

- T

o u

nbloc

k

Um

zu

ent

rie

gel

n -

Pa

ra

des

blo

que

ar

Odb

lok

ow

ani

e -

Om

te

deb

lok

ker

en

-

Отп

ере

ть

2

3

1

Pe

r S

blo

cca

re

- P

our

dé

bra

yer

- T

o u

nbl

ock

Um

zu

en

trie

gel

n -

Pa

ra

des

blo

que

ar

Od

blo

kow

ani

e -

Om

te

deb

lok

ker

en

-

Отп

ере

ть

2

3

1

03.

Lock the gearmotor

Pe

r S

blo

cca

re

- P

our

dé

bra

yer

- T

o u

nbl

ock

Um

zu

en

trie

gel

n -

Pa

ra

des

blo

que

ar

Od

blo

kow

ani

e -

Om

te

deb

lok

ker

en

-

Отп

ере

ть

2

3

1

Pe

r S

blo

cca

re

- P

our

dé

bra

yer

- T

o u

nbloc

k

Um

zu

ent

rie

gel

n -

Pa

ra

des

blo

que

ar

Odb

lok

ow

ani

e -

Om

te

deb

lok

ker

en

-

Отп

ере

ть

2

3

1

Pe

r S

blo

cca

re

- P

our

dé

bra

yer

- T

o u

nbl

ock

Um

zu

en

trie

gel

n -

Pa

ra

des

bloq

uea

r

Od

blo

kow

ani

e -

Om

te

deb

lokk

ere

n -

Отп

ере

ть

2

3

1

04.

Using the key switch, control key or radio transmitter, test the opening and closing of the gate and make sure that it moves in the

intended direction

05.

The test should be carried out a number of times to make sure that the gate moves smoothly, that there are no points of excessive

friction and that there are no defects in the assembly or adjustments

06.

Check the operation of the safety equipment, one by one (photocells, sensitive edges, etc.)

07.

Check the operation of the photocells and any interference with other equipment:

1 - pass a dia. 5 cm length 30 cm cylinder along the optical axis, first close to the TX, then close to the RX

2 - check that the photocells trip in any condition, switching from active to alarm and back

3 - check that tripping the photocell results in the intended response of the control unit: e.g., when tripped during a closing stroke, the gate

changes direction

08.

If the dangerous situations caused by the movement of the door have been safeguarded by limiting the force impact, the user must

measure the impact force according to the EN 12453 standard.

If the adjustment of the “force” is used to assist the system for the reduction of the impact force, try to find the adjustment that gives

the best results.

6.2 - Commissioning

Commissioning can take place only after all testing phases have been terminated successfully (par. 6.1).

Partial or “makeshift” commissioning is strictly prohibited.

01.

Create and store (for minimum 10 years) the technical dossier of the automation that must include: overall design of the automation,

diagram of the electrical connections, risk assessment and relative solutions adopted, declaration of conformity of the manufacturer of

all the devices used (for ROBO use the attached CE Declaration of conformity); copy of the user instruction manual and

the automation maintenance plan

02.

Using the key switch or radio transmitter, test the opening and closing of the gate and make sure that it moves in the intended direction

03.

Prepare the declaration of conformity of the automation system and deliver it to the owner.

04.

Give the owner the user manual (tearout insert)

05.

Prepare and give the owner the maintenance schedule

06.

Prepare and give the owner the maintenance schedule

07.

The force adjustment is an important safety aspect and must be done with care by an expert technician.

Important!

- Adjust the force

to enable the gate to move as intended; higher forces than this can cause injury to animals and persons or damage to property if the

gate collides with an obstacle

08.

Before commissioning the gate, inform the owner in writing about the attendant residual risks.

Summary of Contents for ROBO600

Page 1: ...EN Instructions and warnings for installation For sliding gates Nice ROBO600...

Page 2: ......

Page 30: ...28 English NOTE...

Page 31: ...English 29...