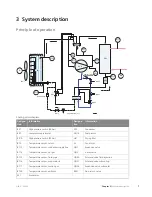

Principle of operation

BT16

BT28

BT17

BT14

BT15

BT13

BT12

BP1

BP2

BT10

M

EP1

EP2

QN2

GQ10

QN30

QN31

QN34

QN1

Underkylare

Avfrostningsprocess

HS1

Kapillärrör

Partikelfilter

Fläkt

0

)DQ

3DUWLFOH ILOWHU

50

41

&DSLOODU\ SLSH ~

(3

%7

%3

%7

*4

%3

(3

41

+6

%7

%7

%7

%7

%7

6XEFRROHU

41

41

41

&DSLOODU\ SLSH

%7

Cooling circuit diagram

Information

Designa-

tion

Information

Designa-

tion

Condenser

EP2

High pressure switch (29 bar)

BP1

Compressor

GQ10

Low pressure pressostat

BP2

Drying filter

HS1

High pressure switch (32 bar)

BP10

Fan motor

M

Temperature sensor, return

BT3

Expansion valve

QN1

Temperature sensor, condenser supply line

BT12

4-way valve

QN2

Temperature sensor, hot gas

BT14

Solenoid valve fluid injection

QN30

Temperature sensor, fluid pipe

BT15

Solenoid valve subcooling

QN31

Temperature sensor, evaporator in

BT16

Expansion valve, subcooler

QN34

Temperature sensor, suction gas

BT17

Non-return valve

RM1

Temperature sensor, ambient

BT28

Evaporator

EP1

7

Chapter 3 |

System description

NIBE™ F2300

3 System description

Summary of Contents for F2300

Page 1: ...Service manual LEK NIBE F2300 Air water heat pump SEM GB 1335 1 M11450 ...

Page 2: ......

Page 33: ...Electrical circuit diagram 31 Chapter 8 Technical data NIBE F2300 8 Technical data ...

Page 34: ...NIBE F2300 Chapter 8 Technical data 32 ...

Page 35: ...33 Chapter 8 Technical data NIBE F2300 ...

Page 36: ...NIBE F2300 Chapter 8 Technical data 34 ...

Page 42: ......

Page 43: ...NIBE AB Sweden Hannabadsvägen 5 Box 14 SE 285 21 Markaryd info nibe se www nibe eu ...