Preparations

TIP

If the ventilation is to be adjusted before heat

pump operation starts, the cooling modules

have to be deactivated in menu 5.2.3.

Pipe

After pipe installation, but before insulating, the system’s

brine side has to be filled with water, vented and pres-

sure-tested. After this, the pipes have to be flushed and

vented. Finally, the system has to be filled with a 28%

mixture of ethylene glycol and water.

The heating medium side should also be flushed and

pressure tested with water.

NOTE

Pay attention to nearby electricity sources

when you are working with liquids.

NOTE

Always wear protective gloves before starting

work.

NOTE

Take care not to damage the environment in

the work area. Risk of flooding.

NOTE

Check that the components necessary for unit

operation are installed and connected to

GreenMaster-HP.

1. Ensure that GreenMaster-HP has not been damaged

during transport.

2. Check that the switch (SF1) is in position " ".

3. Check for water in any hot water heater and climate

system.

4. Follow the start guide, see page 37, when the system

is ready for start-up.

Caution

Check the miniature circuit-breaker and the

motor protection breakers. They may have

tripped during transportation.

NOTE

Do not start GreenMaster-HP if there is a risk

that the water in the system has frozen.

Ventilation

Check that:

1. The fan (GQ2) can rotate freely and there are no

loose parts remaining in the fan chamber.

2. Connector (HR10) next to the fan is in position AUTO.

3. Air filters (HQ10) are clean and intact.

4. The heat exchanger’s (EP10) fins and pipes are clean

and intact.

5. The air ducts are correctly connected to GreenMas-

ter-HP.

6. Sensor (BP12) is connected correctly.

7. Any external accessories are correctly connected.

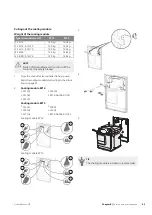

Flushing

Before starting

Make sure that:

1. All shut-off valves are open.

2. All drain, service, vent and filling valves are closed.

3. No other connections in the pipe system are open.

4. Filler connection (XL27) is connected to the prop-

erty’s water supply.

5. Filler connection (XL28) is connected to the drain

with a flexible hose.

6. Pressure gauge (BP6) is not damaged. In the event

of a pressure increase above 3 bar, there is a risk of

safety valves being tripped.

Brine system

XL27

QM34

CM2

QM2.2

QM2.1

CM3

BP6

XL28

XL27

XL28

QM34

GreenMaster-HP

Chapter 6 |

Commissioning and adjusting

32

6 Commissioning and adjusting