17

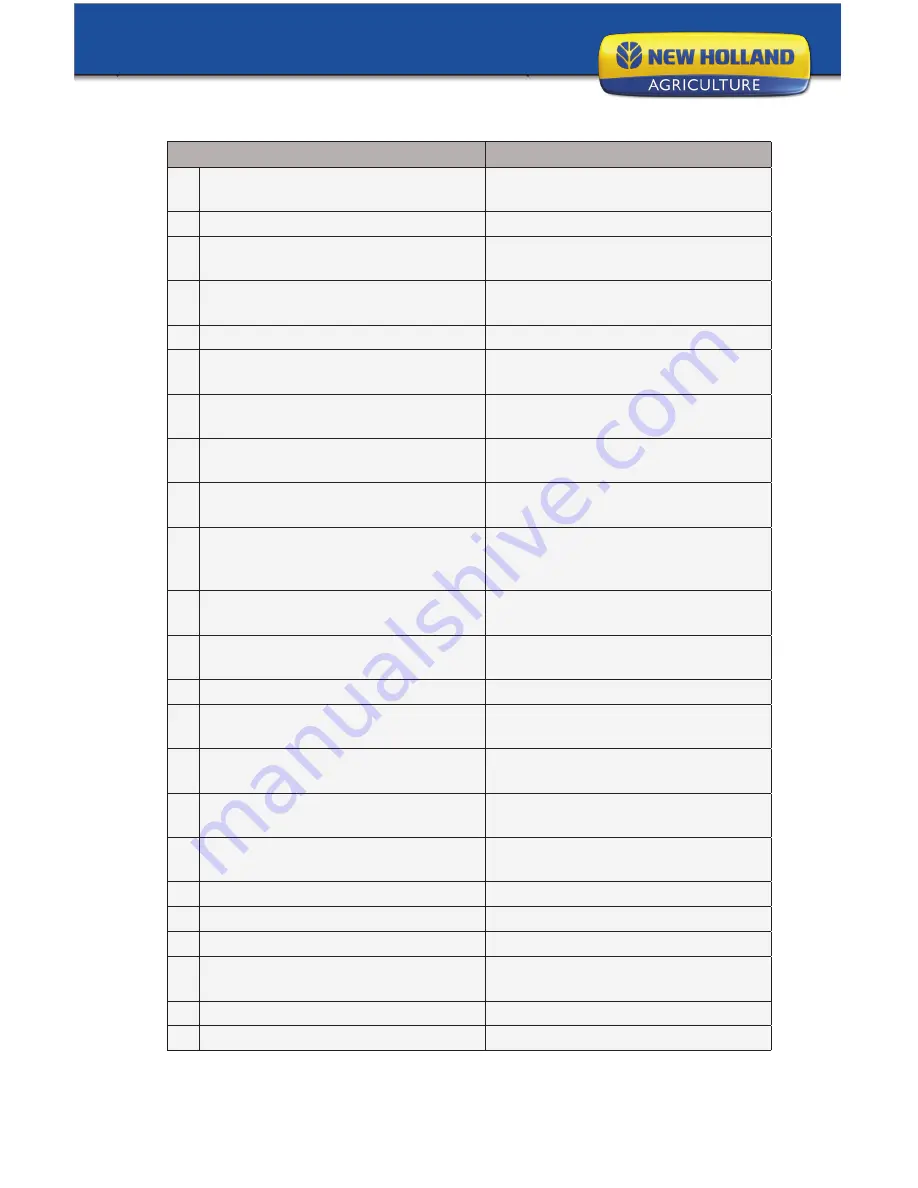

troubleshooting

Possible Cause

Possible Solution

A Low Oil Shutdown

Fill engine with the adequate amount

of oil.

B Cold Engine

Choke engine to start.

C No Fuel

Add gas to engine. Make sure fuel

shutoff valve is open

D Engine not turned ON

Place ON/OFF switch in the ON

position.

E Spark plug wire not attached

Attach spark plug wire to spark plug.

F Compressor viscosity too high for

ambient temperature.

Drain existing lubricant and refill with

proper lubricant.

G Belt tension too tight or sheaves not

aligned.

Check tension/ alignment.

H Air leaks in discharge piping.

Check tubing connections, Tighten

joints or replace as required.

I

Compressor components leaky,

broken, loose.

Inspect components. Clean or

replace as required.

J

Loose flywheel or motor pulley,

excessive end play in motor shaft or

loose drive belts.

Check flywheel, motor pulley, and

crankshaft drive belt tension/align-

ment. Replace or repair as required.

K Leaking check valve or check valve

seat blown out.

Replace check valve.

L Clogged or dirty inlet and/or dis-

charge line.

Clean or replace.

M Defective safety/relief valve.

Replace.

N Pressure switch unloader leaks or

does not work.

Realign stem or replace.

O Inadequate ventilation around

flywheel.

Relocate compressor for better

airflow.

P Leaking, broken or worn inlet un-

loader parts at check valve.

Inspect parts and replace as

required.

Q Excessive condensation in receiver

tank.

Drain receiver tank.

R Detergent lubricant in crankcase.

Replace with proper lubricant.

S Light duty cycle.

Increase duty cycle.

T Lubricant level too high.

Drain excess lubricant.

U Worn cylinder finish.

Deglaze cylinder with 180 grit

flex-hone.

V Low pressure inlet valve leaking.

Inspect, clean or repair as required.

W High pressure inlet valve leaking.

Inspect, clean or repair as required.