11

maintenance

Monthly

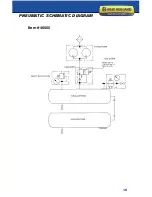

Inspect for air leaks. Squirt soapy water around joints during compres-

·

sor operation and watch for bubbles. Tighten fittings if necessary.

Clean exterior.

·

3 months or 500 hours

Change petroleum lubricant in pump while crankcase is warm.

·

12 months or 1000 hours

Replace air filter element.

·

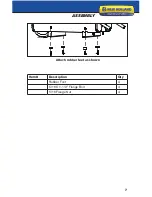

Drive Belt

Belts will stretch in normal use. Properly adjusted, a 5 pound force

applied to the belt between the motor pulley and the pump will deflect

the belt about 1/2”.

To Adjust Drive Belt

Remove belt guard.

1.

Loosen the four fasteners holding the engine to the compressor.

2.

Shift the engine in the proper direction. The belt must be properly

3.

aligned when adjustment is made.

To align belt, visually center engine pulley to compressor pulley.

4.

If necessary, move the pulley on the engine shaft.

5.

Check for proper belt tension (see diagram).

6.

Tighten the four fasteners holding the engine to the top plate.

7.

Attach belt guard.

8.