SECTION 1 - GENERAL INFORMATION

page 1-6

CAUTION!

GENERAL SAFETY PRACTICES

REVIEW this manual and operator’s manual before

servicing equipment.

NEVER allow anyone unfamiliar, untrained, or

complacent to operate the air drill.

ALWAYS USE the jack supplied when unhooking the air

drill.

ALWAYS ensure weight of towing vehicle is heavier than

implement.

NEVER transport the air drill at speeds higher than 30

km/hr (18 mph).

NEVER transport Drill/cart combination with product in

tank.

MAINTAIN YOUR AIR DRILL in proper working

condition. Unauthorized modifications to the machine

may impair function and/or safety and affect machine life.

BE SURE the air drill is securely fastened to a large farm

tractor or an air cart that is attached to a large farm tractor

before operating hydraulics.

USE EXTREME CARE when making adjustments.

KEEP CHILDREN AWAY from all farm equipment.

SERVICING SAFETY PRECAUTIONS

BLOCK the wheels to prevent movement when servicing.

BE SURE the press wheels are blocked and wing lock pins

are in place before servicing or adjusting opener

assemblies or working on the air drill.

The tractor engine should be stopped and the

wheels blocked to prevent any movement during

servicing.

Always be sure that the depth control safety lock

is in place when servicing the air drill.

Always be sure the wings are in field position

before servicing the air drill.

Escaping hydraulic fluid is a serious hazard.

Escaping hydraulic fluid that is under pressure can

penetrate the skin, causing serious injury. Relieve

pressure before disconnecting the hydraulic lines.

Check/tighten all connections before applying

pressure.

Never use your hand to search for leaks. Use a

piece of cardboard or paper. If any fluid is injected

into the skin, seek immediate medical attention.

Gangrene may result if the wound is not treated

within a few hours. Check your hydraulic fluid

containers for warnings concerning the hydraulic

fluids you use.

DO NOT walk within the radius of raised air drill

wings.

Summary of Contents for flexicoil 5000 AD.A

Page 1: ...5000 Air Drill Models AD A and AD B DR 015V2 1 05 Service Manual ...

Page 4: ...This Page is Left Blank Find manuals at https best manuals com ...

Page 8: ...iv This Page is Left Blank Find manuals at https best manuals com ...

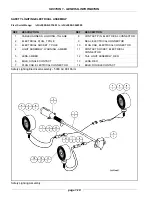

Page 23: ...SECTION 1 GENERAL INFORMATION page 1 15 Transport Lighting Assembly First Serial Range ...

Page 25: ...SECTION 1 GENERAL INFORMATION page 1 17 Transport Lighting Assembly Second Serial Range ...

Page 27: ...SECTION 1 GENERAL INFORMATION page 1 19 ...

Page 29: ...SECTION 1 GENERAL INFORMATION page 1 21 Safety Lighting Assembly Second Serial Range ...

Page 31: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com ...