Operation

214811

28

•

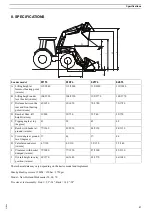

Adjust the tilt angle of the implement when the load

is raised so that the load is not directed towards the

operator.

Fig. 61 Exercise caution when working with raised loads.

5.5.3.1. Machine stability

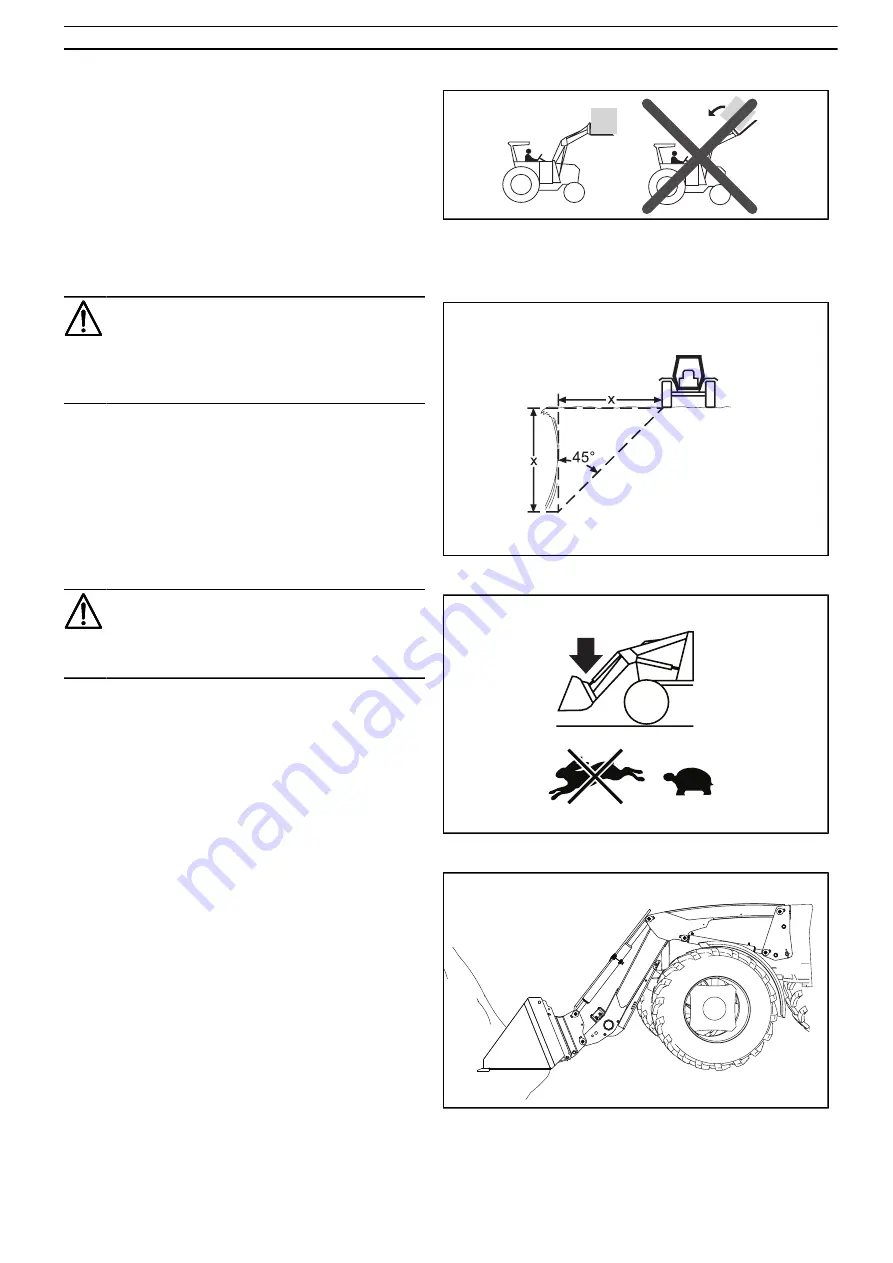

WARNING:

Do NOT work on or close to steep slopes.

The tractor must always be kept a distance from

the edge that is equal to or greater than the

height of the bank or ditch.

•

Operate up and down (not across) slopes. Avoid sudden

starts and stops. Keep the loader as low as possible.

•

Drive the tractor forward up slopes with an empty

bucket. Fill the bucket and then reverse slowly down

the slope.

Fig. 62 Keep at a distance when working near slopes.

WARNING:

Reduce speed before cornering to avoid

overturning the machine.

Avoid sudden turns when driving down slopes.

•

Always leave the transmission in low gear to obtain

engine braking when driving downhill. Do not allow

the tractor to roll freely. Use the same gear for driving

downhill as you did when driving uphill.

•

While driving, lower the loader as far as possible. Keep

in mind that the higher you raise the loader, the higher

the centre of gravity, and thus the risk of the tractor

overturning will increase.

Fig. 63 When cornering, lower the loader and reduce speed.

The bucket is filled most effectively by driving straight

into the stock pile with the bucket level. Raise the loader

slightly while forcing the bucket into the pile to tear

material loose for easier filling. Then roll the bucket back to

contain material.

NOTE:

Remove top layers first when working in deep

material.

Fig. 64 Drive straight in, lift the load and tilt the bucket

backwards.

Summary of Contents for 611TL

Page 2: ......