T E C H L I N E A S ™ D E S I G N G U I D E

NETAFIM @[email protected]

21/12/2009

11

LENGTH OF TECHLINE AS™ROWS:

As with overhead irrigation, friction losses through pipe determine how long a length of

pipe can be.

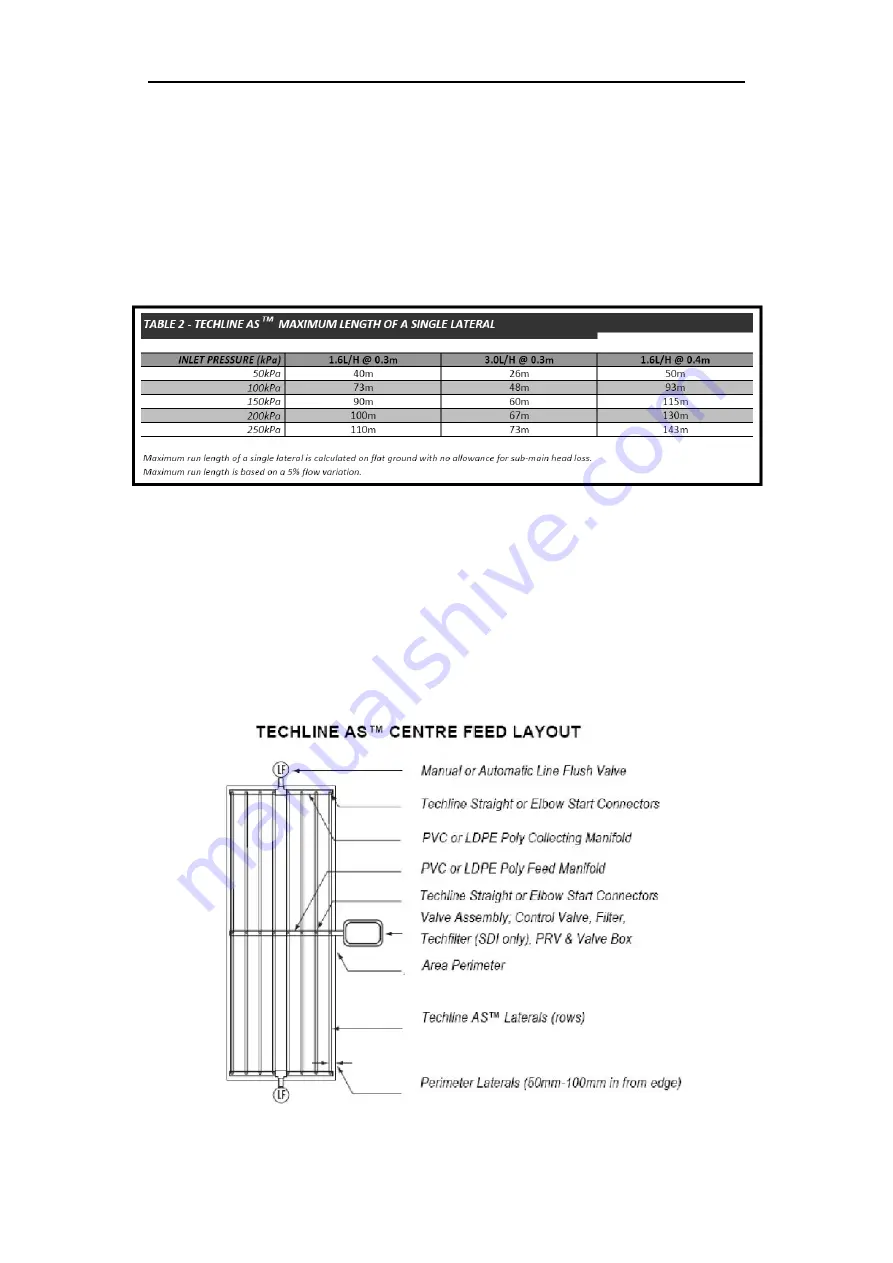

Table 2 has calculated the expected friction loss and shows the maximum length of

single Techline AS™ lateral within a zone.

The chart also determines what the operating pressure of the zone needs to be.

Example – If you have a 130m lateral of 1.6L/H @ 0.4m Techline AS™, it will need 200

kPa to operate properly. If it is from 130m – 143m long, it will need 250kPa.

Note: We

will discuss how to regulate pressure on page.18.

CENTRE FEED GRID LAYOUTS:

You can increase the length of laterals by centre-feeding the zone. By doing so, you

can have a length of Techline AS™ as indicated in Table 2 going out in each direction,

effectively doubling the maximum lateral run length. This is just like we discussed with

the “LITE” layout on page 6.

Where layout flexibility exists, Centre Feed layouts are an excellent design method.

They allow for the most even flow of water through the zone.

They are an excellent option for median strips and other large homogenous areas.