ELECTRICAL INSTALLATION, WIRING AND TROUBLESHOOTING

Nederman Customer Service & Technical Support [email protected]

+1 (336) 821-0800

3

Section 1.0 – Preface

Nederman S

‐

Filters utilize high

‐

efficiency induction motors that have a high startup current, known as “Inrush

Current”, that lasts for a brief period, usually less

‐

than 10

‐

seconds. When the motor first starts, it will

experience up to 8x the FLA of the motor current. This will decrease rapidly until the motor reaches steady

state. If the motor does not turn over, please see Section 4.0 Troubleshooting.

There are specific electrical codes and standards outlined within this manual that need to be employed when

making the electrical connections.

Failure to adhere to the procedures outlined in this document WILL VOID the Nederman product warranty.

Section 2.0 – Circuit Sizing

Refer to Table 1 and 2,

1 and 3

‐

Phase S

‐

Filter Motor Circuit Sizing Tables

, to appropriately size the branch circuit

conductors and circuit breaker size. The data in this table is based on the 2020 NEC and is to be used as

recommendations only

. Final discretion is the responsibility of the Licensed Electrician, local codes,

regulations, and the AHJ.

Due to the inrush current, the fusing/breaker must be sized larger to protect the wiring in the event of a short

‐

circuit. The motor-overhead, not the breaker, provides the motor protection and should be set as close to the

FLA (Full

‐

Load Amperage) of the motor as possible to maximize motor protection.

The minimum conductor size listed in the table is calculated based on 75°C wire. If using a different type of

wire, or the dust collector is located a significant distance from the main panel, the wire size must be adjusted

accordingly.

Note: AWG #12 is the minimum acceptable wire size

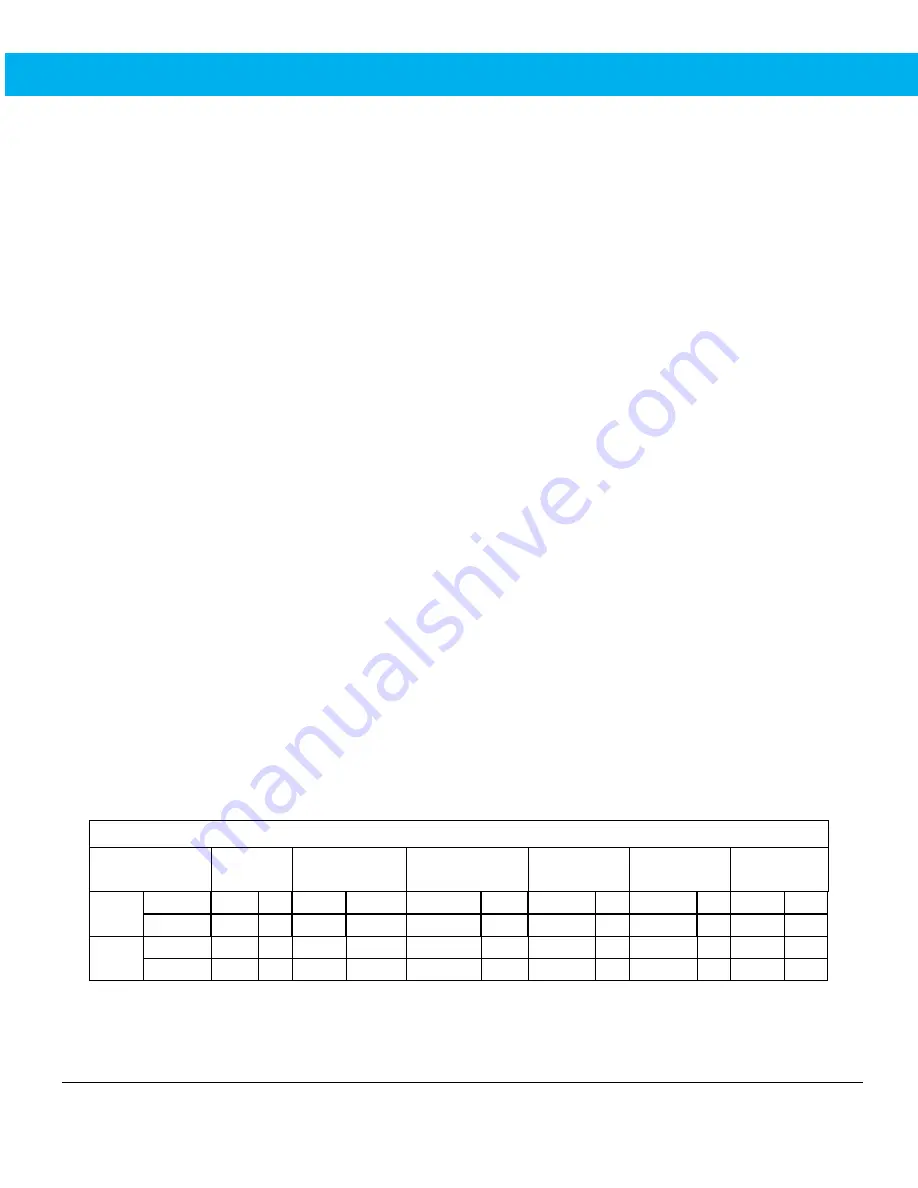

TABLE 1 - 1 Phase S-Filter Motor Circuit Sizing Table

8

Service Factor 1.0

Motor FLA

1

Conductor Size

2,7

Inverse Time

Breaker Size

3

Time

‐

Delay Fuse

4

Non Time

‐

Delay

5

O/L Setting

6

S

‐

500

208V

22.8

A

8

AWG

80

A

60

A

100

A

26

A

230V

20.2

A

8

AWG

70

A

50

A

90

A

23

A

S

‐

750

208V

35

A

6

AWG

110

A

80

A

150

A

40

A

230V

30

A

8

AWG

100

A

70

A

125

A

35

A