FlexPAK 800/1000

EN

30

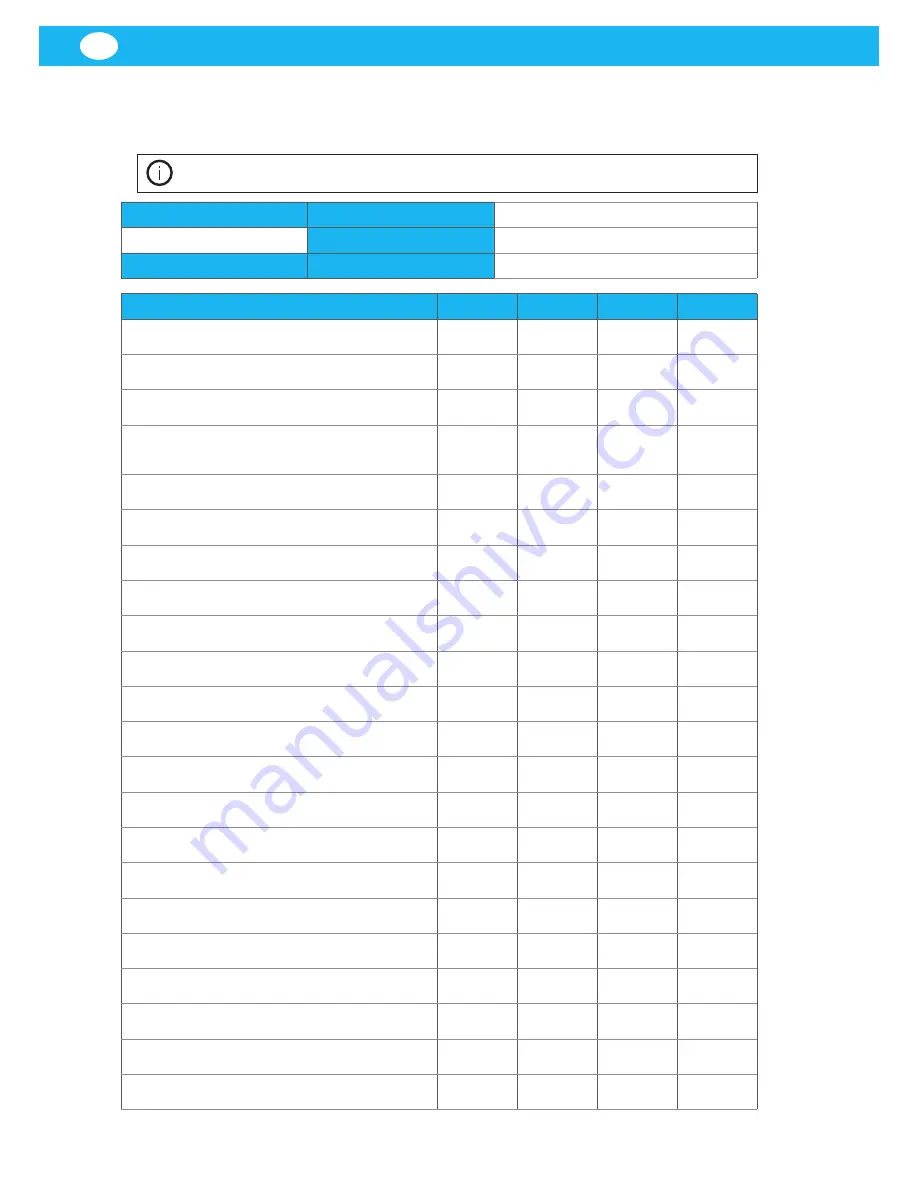

Appendix B: Service protocol

Copy the service protocol, fill it in and save it as a service record.

NOTE!

If the results of the checks (for example, measured values) differ significantly from

previous results, investigate more carefully.

Unit No.

Date:

Operating hours:

Performed by:

Control items

Result

Result

Result

Result

Previous service record

Inspect/clean outside the unit

Remove dust deposits, clean work area

Remove corrosion by grinding, apply primer and touch up

paint

Vacuum, measure negative pressure

Cooling valve

Bearing motor

Fan

Cooling fan, motor

Bearing motor / fan

Safety switch

Box / housing

Main switch

Cable harness

Electrical connection points

Ground (earth) connection

Indicator lamps

Inverterr

Cooling air filter, functional control, frequency inverter

Cooling air filter, exchange

Rated current

Sealings

Summary of Contents for FlexPAK 1000

Page 2: ...FlexPAK 800 1000 2 ...

Page 3: ...FlexPAK 800 1000 3 Figures 4 English 11 ...

Page 6: ...FlexPAK 800 1000 6 1 2 3 4 5 6 7 14 13 12 11 9 8 10 7 6 ...

Page 8: ...FlexPAK 800 1000 8 9 10 1643 1mm 65 662 1mm 26 2 1771 4 1mm 70 2 1 4 5 6 8 7 9 3 1 ...

Page 9: ...FlexPAK 800 1000 9 11 12 14 13 ...

Page 10: ...FlexPAK 800 1000 10 1 0 m 39 4 A B C 16 17 15 Min 2 1m 83 A A A A C ...

Page 32: ...FlexPAK 800 1000 EN 32 ...

Page 33: ......

Page 34: ...www nederman com ...