NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO”

07/10/2005

page 35 / 42

The vending machine KORO was designed to operate for a long time without malfunctions; however in order to

ensure excellent reliability periodic maintenance is necessary.

Such maintenance must be performed according to the number of selections made and the time lapsed.

Periodic and correct maintenance ensures reliability, constant quality and also guarantees safety standards over

time.

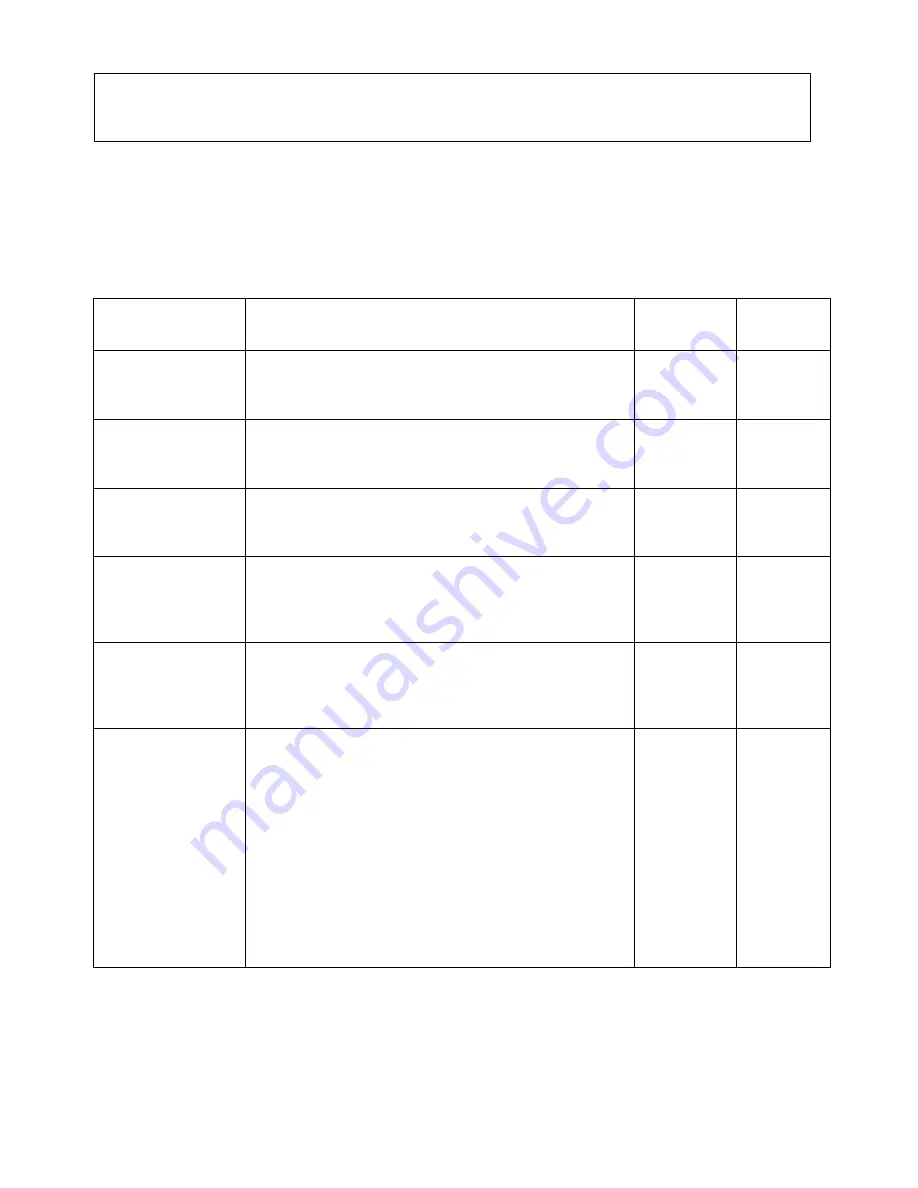

The following table indicates the functional units that must be subjected to periodic maintenance and the

frequency of maintenance. For the operations to be carried out, refer to the specific

Functional unit manuals.

Name of unit

DESCRIPTION OF OPERATION

N. of

selections

Max

frequency

Espresso brewer

unit

1)

Check state of filters and wear of silicone O-ring seal

2)

Replace upper and lower filters and related seals

3)

Descale the internal vent hole and lubricate with specific

food-safe grease

5000

8000

30.000

1 month

6 months

annual

Fresh brewer unit

1)

Check state of filters and wear of silicone O-ring seal; see

details in the functional unit manual for FB coffee brewing

2)

Open the unit and check the state of wear and internal

lubrication and if necessary replace and lubricate

4000

40.000

1 month

annual

Mixer unit

1)

Check the water tightness in the axial bush and the

correct assembly, if necessary replace.

2)

Check the wear of the motor brushes and clean off the

excess of carbon powder

50.000

annual

Boiler and

solenoid valve

assembly

If the boilers and the solenoid valves operate with soft water

or are fitted with specific softener filters, the should be no

need of periodic maintenance; otherwise periodically check

the grade of scaling and if necessary proceed to complete

descaling

According to

the water

hardness

Every 6

months

Steam exhauster

unit

There is not need of any particular maintenance

For perfect functioning, it is necessary that the powder

removal boxes be emptied periodically.

In addition, daily cleaning ensures also maximum hygiene of

the machine.

Every day

Coffee grinder

assembly

The motor was designed to operate for more than 200000

grinding cycles and the grinding wheels can ensure correct

grinding for at least 50000 cycles.

However, these values can vary because of possible

impurities in the coffee (pebbles, pieces of hard wood, etc.),

therefore it is advisable, except for premature wear, to

check and if necessary replace the grinding wheels every

50000 cycles.

Every 200000 cycles check the state of wear of the

ratiomotor brushes, if necessary replace and clean off the

wear residues.

In addition, every month check the correct positioning of the

grinding wheels and if necessary adjust to the correct

setting by means of the knurled knob.

50000

200000

4000

Every year

month

Extraordinary maintenance is carried out in the event of possible malfunctions.

For the most typical problems the vending machine is fitted with sensors that inform the software about any

malfunction. The following tables list the possible malfunctions and possible remedies.

27 – ROUTINE & EXTRAORDINARY

MAINTENANCE PROGRAM