Chapter 2: Troubleshooting

19

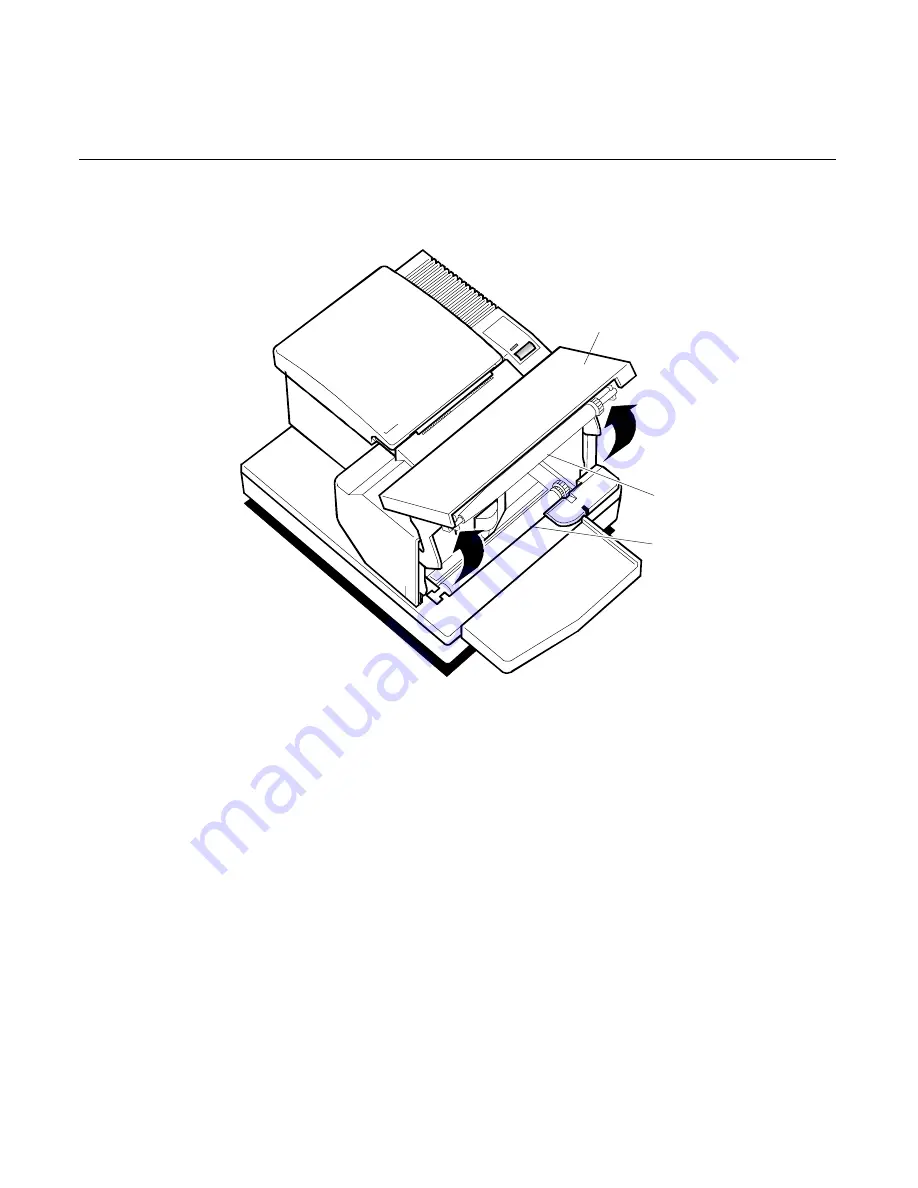

Bumps on Paper Feed Rolls

Front

Cover

Pressure

Roller

Feed

Roller

Open the front cover and slowly rotate the feed and pressure rolls. As

you rotate each roll, rub the surface from end to end, checking for

bumps or high spots. Remove any significant bumps such as those

caused by paper debris buildup. Check both rolls. If bumps have been

found and removed, repeat the MICR read test.

Platen Gap Tightness

If the platen gap is too tight, it may create a drag on documents,

interfering with a smooth feed. Measure and reset the platen gap. For

more information, see the 7156 Service Guide. Perform the MICR

adjustment and repeat the MICR read test. For more information on

adjusting the MICR, see “In-Place MICR Adjustment” on page 20.

Summary of Contents for 7156

Page 4: ...ii MICR Operation and Trouble Shooting Guide...

Page 28: ...20 Chapter 2 Troubleshooting...

Page 35: ......

Page 36: ...B005 0000 1057 Dec 1998 Printed on recycled paper...