BIM 1020/2005/03

3

www.nord.com

AXIAL RETENTION

Each drive shaft must be retained in place relative to the gear

reducer. Or each gear reducer must be retained in place relative

to the drive shaft. Either way NORD recommends the use of

shaft shoulders, locking collars or FIXING ELEMENTS to axially

retain the shaft or gear reducer in position.

SET SCREWS

If set screws are used for axial retention, they should be tightened

evenly. Flats may be filed on the driven shaft and a thread-

locking adhesive used for more position retention.

SNAP RING RETENTION

Placing external snap rings on drive shafts must be performed

with caution. The groove, which the snap ring fits into, may

weaken the drive shaft causing premature failure. NORD does

not recommend this type of shaft retention.

THRUST PLATE

In applications, which are subject to high vibratory loads, a thrust

plate will provide greater resistance to axial movement. Follow

the manufacturer’s recommendations for assembly.

SHRINK DISC

If a shrink disc is used to secure a reducer hollow shaft to the

driven shaft, follow this assembly procedure. Start with the shrink

disc mounted onto the extension of the hollow shaft disc locking

bolts loosened.

1.

Clean reducer bore and mating solid shaft to be free of any

lubricants or dirt.

2.

Slide reducer onto the solid shaft until it is about half way

through.

3.

Lubricate the remaining portion of the solid shaft with a #2

grease or similar lubricant. This part will be located under

the bronze bushing.

Do not install grease under the

shrink disc gripping area.

Finish installing the solid shaft

into the reducer hollow bore.

4.

Finger tighten all shrink disc bolts. Now, moving a circular

pattern, tighten each shrink disc locking bolt 1/4 to 1/2 turn.

Do not use criss cross pattern.

Continue tightening in the

same circular direction with 1/4 or 1/2 turn increments until

all bolts reach the specified bolt tightening torque. Bolt

tightening torque is shown on the shrink disc label for the

particular unit.

5.

Run unit for 24 hours, then retighten shrink disc locking bolts

to the proper bolt torque as indicated above.

TORQUE REACTION ARM

On the shaft mount ‘Clincher’, torque is reacted through the

integral torque tab, which is part of the casting. Commonly,

NORD’s optional RUBBER BUFFER bushings are installed on

each side of the integral torque tab to dampen torque shocks and

allow for mis-alignment received from the machinery during

operation.

Torque arm connection fabrications should always be mounted

perpendicular to a line through the output shaft center and the

point at attachment of the torque arm to the unit housing. In this

position the minimum load on the attachment structure arm will be

experienced. The attachment structure must be rigid and may not

deflect under any load. Doing so will place extra loads on the

output bearings of the reducer.

PRIME MOVER MOUNTING

AIign the prime mover to the reducer-input shaft using shims

under the feet. Make sure that the feet are supported. DoweI the

prime mover to its foundation.

SHAFT CONNECTIONS

When connecting shafts to either the input or output of the

reducer, consider the foIIowing instructions.

FITS

CIearance or interference fits for coupIing hubs shouId be in

accordance with ANSI/AGMA 9002-A86 or as follows.

Output and Input shaft Diameter toIerance

Metric

(mm)

d

18 = +0.012/+0.001

!

18

d

30 = +0.015/+0.002

!

30

d

50 = +0.018/+0.002

!

50

d

80 = +0.030/+0.011

!

80

d

120 = +0.035/+0.013

!

120

d

180 = +0.040/+0.015

Inch

d

1.750 = +0.0000/-0.0005

!

1.750 = +0.0000/-0.0010

Output and Input shaft DriII and tap shaft end

Metric (mm)

d

16 = M5

!

16

d

21 = M6

!

21

d

24 = M8

!

24

d

30 = M10

!

30

d

38 = M12

!

38

d

50 = M16

!

50

d

85 = M20

!

85

d

130 = M24

Inch

d

0.438 = #10-24 x 0.4 deep

!

0.438

d

0.813 = 1/4-20 x 0.6 deep

!

0.813

d

0.938 = 5/16-18 x 0.7 deep

!

0.938

d

1.125 = 3/8-16 x 0.9 deep

!

1.125

d

1.375 = 1/2-13 x 1.1 deep

!

1.375

d

1.875 = 5/8-11 x 1.4 deep

!

1.875

d

3.250 = 3/4-10 x 1.7 deep

!

3.250 = 1-8 x 2.2 deep

Outboard pinion and sprocket fits shouId be as recommended by

the pin sprockets with interference fits shouId be heated

according to the manufacturer’s recommendations, generaIIy

250

q

F to 300

q

F, (120

q

C to 150

q

C) before assembIing to the shaft.

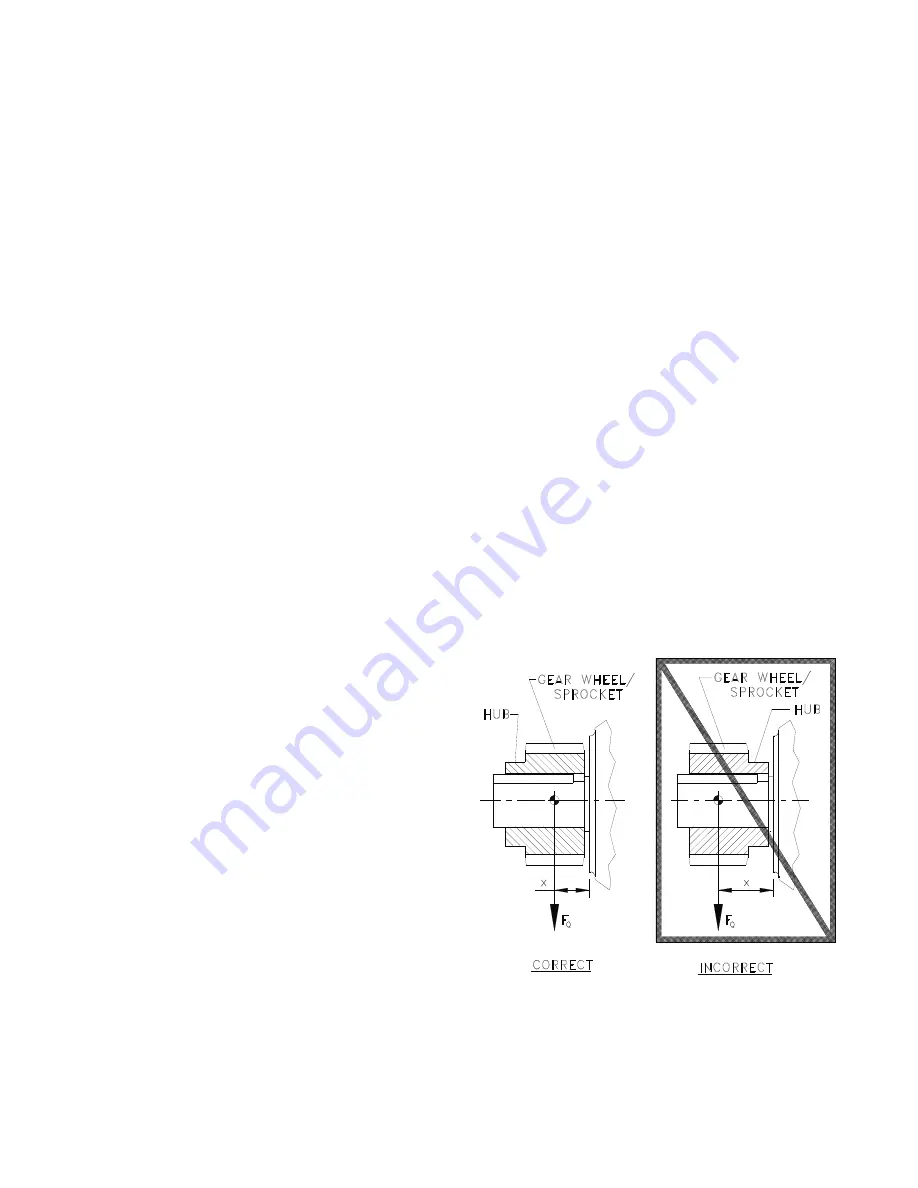

LOCATION

CoupIing hubs shouId be mounted fIush with the shaft ends,

unIess specificaIIy ordered for overhung mounting. Pinions,

sprockets and sheaves shouId be mounted as cIose as possibIe

to the unit housing to minimize bearing Ioads and shaft

defIections.

Summary of Contents for Brawn mixer BTO Series

Page 2: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 4: ......

Page 6: ......

Page 36: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 37: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 38: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 39: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 40: ......