9

INTERFACING GATEWAY TO DEVICES

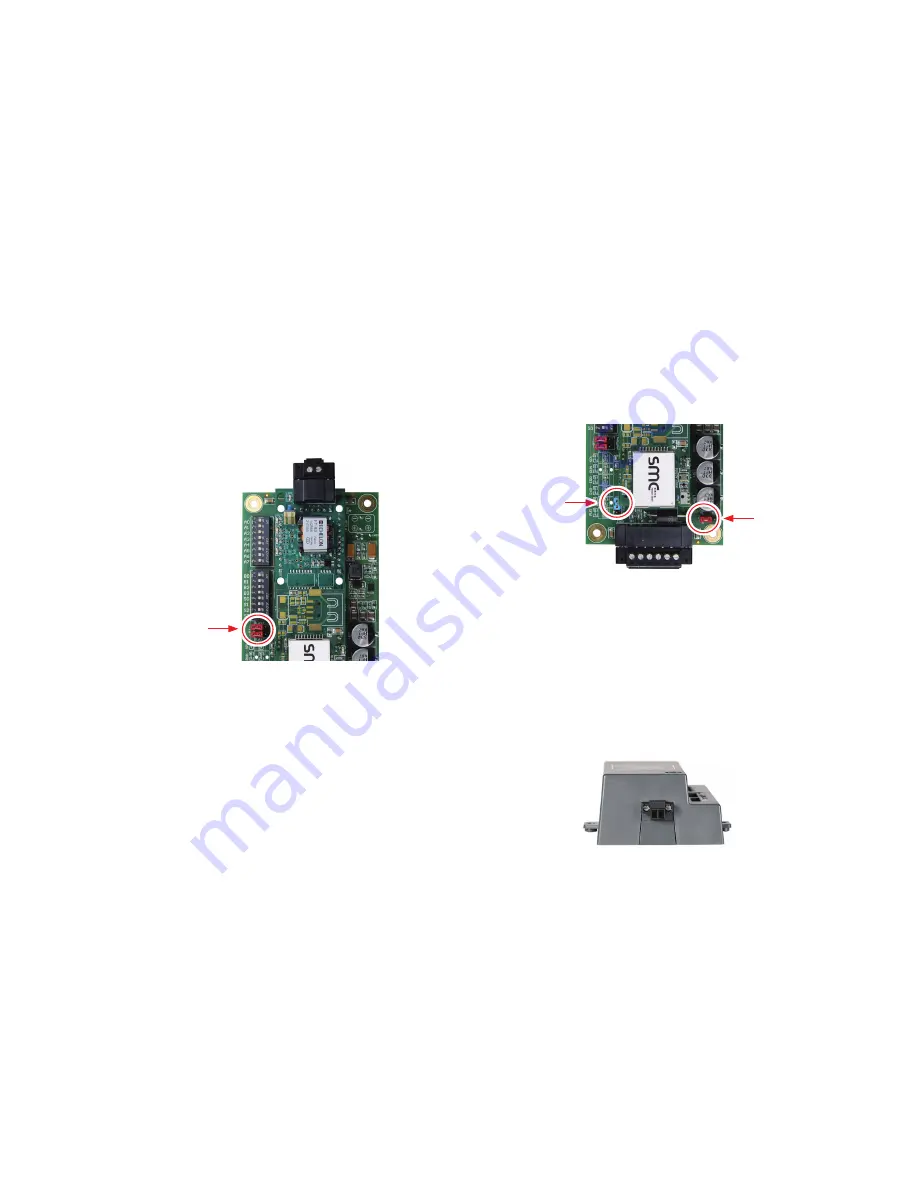

4.2.1 Biasing the RS-485 Device Network

●

An RS-485 network with more than one device needs to have

biasing to ensure proper communication. The biasing only

needs to be done on one device.

●

The gateway has 510 ohm resistors that can be used to set the

biasing. The gateway’s default positions from the factory for the

biasing jumpers are OFF.

●

The OFF position is when the 2 red biasing jumpers straddle the

4 pins closest to the outside of the board of the gateway. (Figure

●

Only turn biasing ON:

-

IF the BMS cannot see more than one device connected to

the gateway.

-

AND all the settings (COM settings, wiring, and DIP

switches) have been checked.

●

To turn biasing ON, move the 2 red biasing jumpers to straddle

the 4 pins closest to the inside of the board of the gateway.

RS-485 Bias

Switch

(off)

Figure 8: RS-485 Biasing Switch on the Gateway

4.2.2 End of Line Termination Switch for the RS-485

Device Network

●

On long RS-485 cabling runs, the RS-485 trunk must be properly

terminated at each end.

●

The gateway has an end of line (EOL) blue jumper. The default

setting for this blue EOL switch is OFF with the jumper

straddling the pins closest to the inside of the board of the

gateway.

-

On short cabling runs the EOL switch does not to need to be

turned ON.

●

If the gateway is placed at one of the ends of the trunk, set

the blue EOL jumper to the ON position straddling the pins

closest to the outside of the board of the gateway.

●

Always leave the single red jumper in the A position (default

factory setting).

RS-485 EOL

Switch

(off)

Leave in

Position A

Figure 9: RS-485 End-Of-Line Termination Switch on the Gateway

4.3 Wiring LonWorks Devices to the

LonWorks Terminal

●

Wire the LonWorks device network to the LonWorks Gateway

Terminal.

-

Use approved cable per the FT-10 installation guidelines.

●

LonWorks has no polarity.

Figure 10: LonWorks Terminal