If the yoke is the full-round type, place the protractor base on the outside surface of the

machined shoulder as shown in

Figure 8-63

. The protractor should read the angle of the

engine/transmission inclination. If the output yoke is more than 1l degree out of vertical

alignment, it is either loose or it is distorted and should be replaced.

Figure 8-62 - Checking vertical

alignment of a half-round yoke.

Figure 8-63 - Checking vertical

alignment of a full-round end

yoke.

When checking the input yoke attached to the pinion shaft of a drive axle, jack up one

wheel and rotate the wheel until the lugs of the yoke are aligned vertically. Then

measure the vertical alignment of the yoke, using the foregoing procedure just

described for checking the transmission output yoke. Refer to

Figure 8-64

, which

outlines a driveshaft troubleshooting guide.

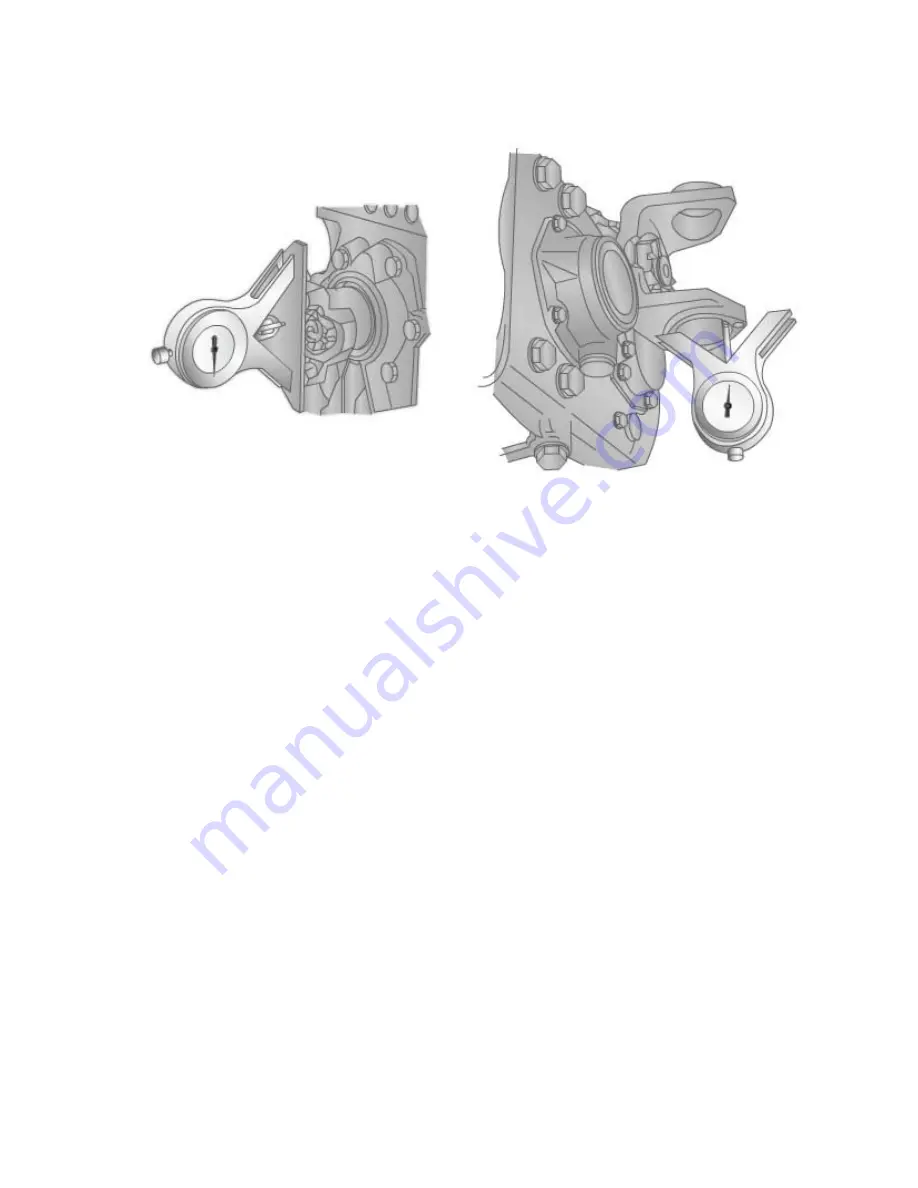

4.10.0 PTO Driveshafts

In some applications, an auxiliary power unit, such as a pump, can be directly mounted

to the power takeoff (PTO) assembly (

Figure 8-65, View A

). However, it is more

common to locate PTO driven units remotely and drive them using a driveshaft (

Figure

8-65, View B

).

NAVEDTRA 14050A

8-69