31

FLUSH SOLUTION TANK AND PUMP: (continued from previous page)

•

Use the vacuum hose to vacuum the remaining acid solution out of the solution tank.

•

Pour two or three gallons of clean water into the solution tank.

•

Connect a solution hose to the solution outlet female quick connect. The other end of the hose

should have an open quick connect or no quick connect to allow full flow out of the hose.

•

Direct the end of the open flow solution hose into the recovery tank vacuum barb.

•

Turn one or both of the vacuums ON and turn the solution pump ON. Let the pump run until most

of the water has been pumped out of the solution tank.

Do not let the pump run dry. Turn the

pump OFF before the water gets to the bottom of the tank.

•

Turn the vacuums OFF and disconnect the open flow solution hose.

•

Place a bucket under the drain valve and open the drain valve to drain the water out of the recovery

tank.

•

Close the drain valve and dispose of the water.

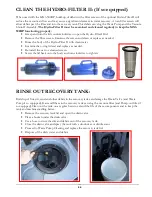

CLEAN PUMP INLET FILTER

A restricted Pump Inlet Filter can prevent the solution pump from providing adequate pressure for cleaning.

A restriction or air leak on the pump inlet hose can also

damage the solution pump check valves and plunger

seals.

CAUTION: Before proceeding with this procedure,

make sure both power cords are disconnected.

•

To examine the filter, open the solution tank lid

on the front of the machine. The filter is in the

bottom of the solution tank.

•

Grasp the filter cap and unscrew the filter from

the brass nipple by turning counter-clockwise.

Clean or replace the filter as needed (PP14-

806504).

•

To examine the pump inlet hose, release the latches on the front/bottom of the machine and tilt the

tanks off of the base assembly.

•

Examine the hose for kinks, clogs or holes and repair or replace the hose as needed.

(Replacement Hose: NM5086 – sold per foot)

•

Tilt the tanks back onto the base and secure the latches.

SOLUTION FILTER

PP14-806504

Inside View: MX3-500RP Solution Tank

Vacuum acid solution out of

Solution Tank

Summary of Contents for MX3-500RP

Page 1: ...1 LMANN14 Revised 06 04 2014 Nautilus MX3 500RP Operating Manual...

Page 38: ...38 OPTIONAL AUTO FILL FLOAT VALVE ASSEMBLY NM5740...

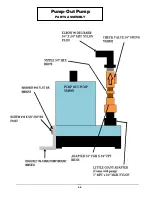

Page 40: ...40 Pump Out Pump PARTS ASSEMBLY...

Page 41: ...41 1 2 3 5 4 4 6 7 8 9 10 11 12 3 8 9 8 9 8 9 39 2...

Page 48: ...48 2 39 1 72 73 73 67 9 30 31 82 83 2 83 82 84 INSIDE SOLUTION TANK BOTTOM VIEW SOLUTION TANK...

Page 50: ...50 92 91 95 94 112 13 14 14A 104 105 1 39 PUMP OUT CONNECTIONS...