27

Maintenance

Proper maintenance is required to keep the MX3-500RP operating properly, prevent

downtime and to extend the life of your equipment.

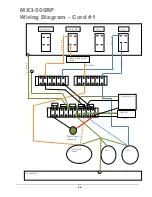

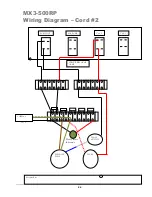

WARNING: Disconnect electrical power before performing any service or

maintenance inside machine base or before testing or repairing switches or power

cords. Failure to do so may result in severe personal injury or death.

OPERATION

INTERVAL Page #

CLEAN CHEMICAL FEED FILTER & FOOT VALVE Daily – After Each Job

28

CLEAN VACUUM SHUTOFF ASSEMBLY SCREEN

Daily – After Each Job

28

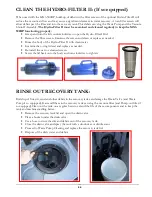

CLEAN HYDRO-FILTER II

Daily – After Each Job

29

RINSE OUT RECOVERY TANK

Daily

29

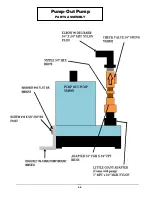

CLEAN WASTE PUMP-OUT PUMP

Daily

30

FLUSH SOLUTION TANK AND PUMP

Daily

30

CLEAN PUMP-INLET FILTER

Weekly – As needed

31

FLUSH CHEMICAL SYSTEM

Monthly

32

LUBRICATE PRESSURE REGULATOR O-RINGS

Monthly

33

CLEAN DRAIN VALVE

As needed

34

STORAGE PREP – FREEZE PROTECTION

As needed

35

Section

3

Summary of Contents for MX3-500RP

Page 1: ...1 LMANN14 Revised 06 04 2014 Nautilus MX3 500RP Operating Manual...

Page 38: ...38 OPTIONAL AUTO FILL FLOAT VALVE ASSEMBLY NM5740...

Page 40: ...40 Pump Out Pump PARTS ASSEMBLY...

Page 41: ...41 1 2 3 5 4 4 6 7 8 9 10 11 12 3 8 9 8 9 8 9 39 2...

Page 48: ...48 2 39 1 72 73 73 67 9 30 31 82 83 2 83 82 84 INSIDE SOLUTION TANK BOTTOM VIEW SOLUTION TANK...

Page 50: ...50 92 91 95 94 112 13 14 14A 104 105 1 39 PUMP OUT CONNECTIONS...