XR12 Operations and Maintenance Manual

Operating the transmitter

Issue 3.1 2013-03-14

Page 2-5

Using GUI pages

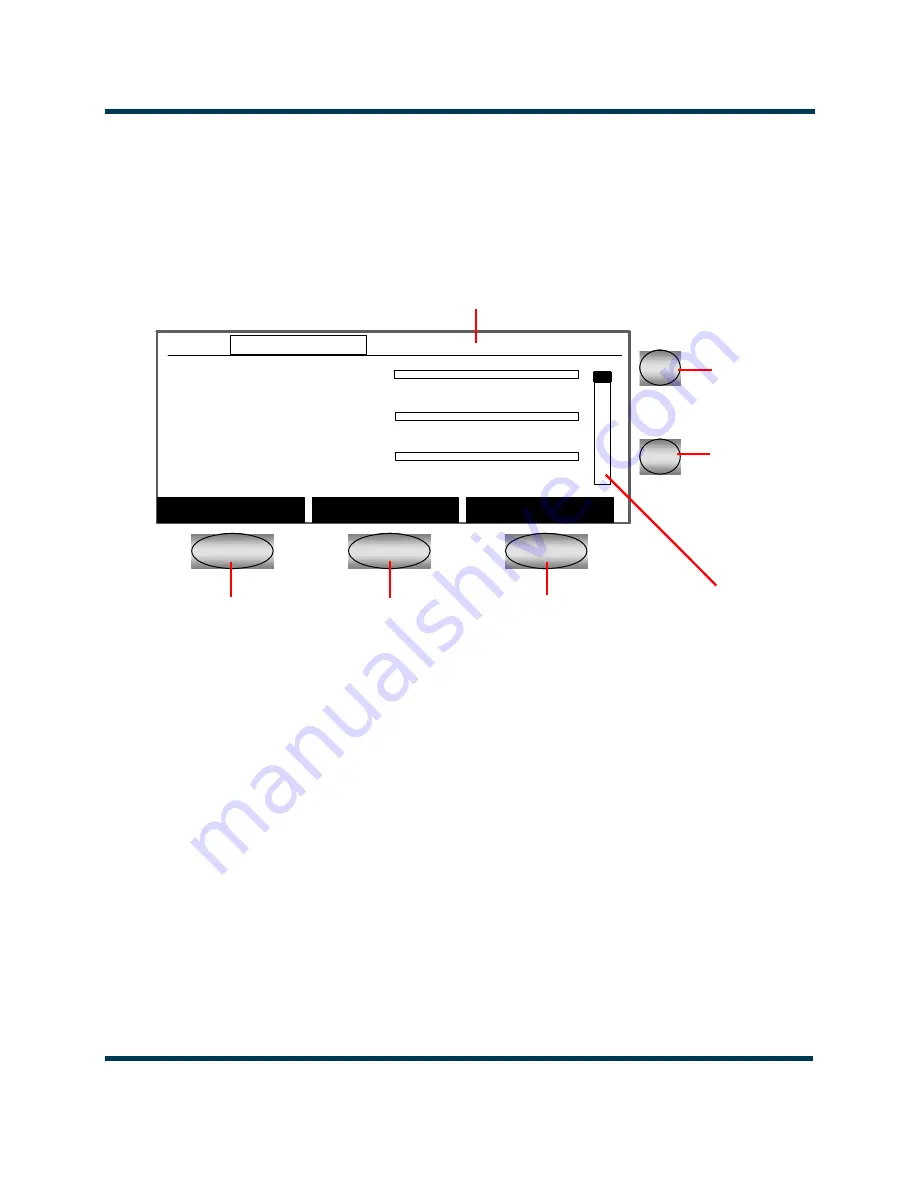

Each GUI page provides information about a specific transmitter function. The status bar at the top

of every page shows the time, the current power, the Preset Scheduler status (M for manual or A for

automatic), the current preset number, the active power modules, the power module transfer function

status, the active exciter, and the exciter transfer function status.

Five buttons, called

soft keys

, appear below and to the right of the GUI screen. These buttons let you

scroll through information, move from page to page, and change settings. The actions that take place

when you press

Soft Key 1

,

2

, or

3

are shown in the black labels on the screen directly above each soft

key (e.g.,

Edit

or

Back

).

Viewing information.

When you move to a new GUI page, the page is displayed in the

Select

mode. In the

Select

mode, press the desired

Soft Keys

to move the cursor (the selected area of the

screen), and scroll through lists or menus. You can use the

Up

and

Down

buttons to scroll through

information on any page that has a vertical scroll bar.

Editing settings.

In screens where you can edit information, use the

Up

and

Down

buttons to

move the cursor and highlight the information you wish to change, then press

Soft Key 2

(the

Edit

button) to enter

Edit

mode. After editing the information, press the

Save

button

to save the changes,

or the

Cancel

button to discard your changes, and return to the

Select

mode.

Soft Key 1

Soft Key 2

Soft Key 3

Up

Down

Forward Power:0.00W

0

5

10

Reflec. Power: 0W

0

500

1000

Total DC Curr: 0.0A

0

25

50

Menu

Status

Preset

10:18 0.00kW M-1 B+1 PM:A Man Ex:A Man

n

n

n

5

6

Forward Power:0.00W

0

5

10

Reflec. Power: 0W

0

500

1000

Total DC Curr: 0.0A

0

25

50

Menu

Status

Preset

10:18 0.00kW M-1 B+1 PM:A Man Ex:A Man

Forward Power:0.00W

0

5

10

Reflec. Power: 0W

0

500

1000

Total DC Curr: 0.0A

0

25

50

Menu

Status

Preset

10:18 0.00kW M-1 B+1 PM:A Man Ex:A Man

n

n

n

5

6

Status Bar

Scroll Bar

Summary of Contents for XR12

Page 2: ...left blank intentionally...

Page 4: ...left blank intentionally...

Page 10: ...XR12 Operations and Maintenance Manual Page x Issue 3 1 2013 03 14...

Page 18: ...XR12 OPERATIONS AND MAINTENANCE MANUAL PAGE XVIII VERSION 3 1 2013 03 14...

Page 63: ...XR12 Operations and Maintenance Manual Using the event log Page 3 8 Issue 3 1 2013 03 14...

Page 69: ...XR12 Operations and Maintenance Manual Routine maintenance Page 4 6 Issue 3 1 2013 03 14...

Page 80: ......