NATIONAL HYDRO 70" TRIPLEX

®

21

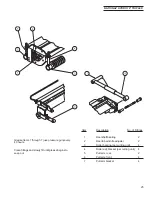

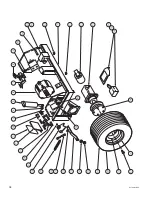

8.17COUPLING ALIGNMENT

To prevent coupling failures proper shaft alignment

between the pump shaft and engine shaft is

required. Following these steps will ensure proper

alignment.

1.

Remove flex coupling disk (Part# 591181) from in-

between coupling halves.

2.

Rotate both coupling halves to a vertical position to

check up and down alignment.

3.

Loosen the four fasteners mounting the hydraulic

motor to the frame.

4.

Rotate the hex adjuster (counter clockwise to raise,

clockwise to lower) to achieve the proper height of

the hydraulic motor pump shaft. It is recommended

to check alignment on the rounded surfaces of the

couplings.

5.

Tighten hydraulic pump mounting fasteners.

Recheck alignment.

6.

To adjust forward and back alignment, rotate

couplings 90° to a horizontal position and loosen

the four fasteners mounting the engine to the

frame.

7.

Slide engine forward and back until proper

alignment is achieved. Retighten fasteners.

8.

Remount coupling disk. (Use of a thread locking

formula is recommended).

COUPLING

HALVES

HEX

ADJUSTER

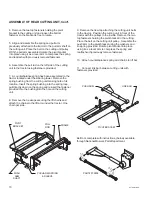

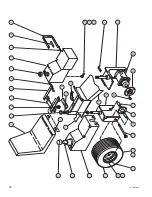

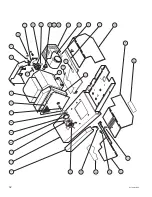

BELT REPLACEMENT, Continued

1, Gently roll the pivot bracket off of the cutting unit.

Now the belts can easily be removed from the reel

pulleys.

2. Remove the top two bolts on the rear cutting unit

(right side only) pivot bracket. (Noting this bracket

is under spring pressure). Loosen the bottom bolt

and use it as a pivot point. Roll back the pivot

bracket allowing the spring pressure and belt

tension to be released. (Use of a crescent wrench

to get extra leverage is very helpful). Remove belt

from rear cutting unit pulley.

3. To remove belts from the tractor you must remove

the left front cover to access the main engine drive

belts. Remove the front belt guide on the engine

drive pulley, with clutch disengaged, the two main

drive belts and the left wing cutting unit belt, can

now be removed.

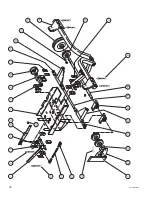

4. Removal of the right wing and rear cutting unit belts

can be done by removing the two capscrews

holding the bearing mounting bracket in place.

With capscrews removed rotate the bearing and

bracket creating space to remove both belts.

For reinstallation of new belts reverse these

steps. Taking care to tighten all mounting fasteners and

making sure all belts, pulleys, and pulley scrapers are

all in alignment.

REMOVE

FASTENERS

ROTATE BEARING

AND BRACKET

FOR BELT REMOVAL

Summary of Contents for HYDRO 70" TRIPLEX

Page 28: ...HY70OM 8 99 28 ...

Page 30: ...HY70OM 8 99 30 ...

Page 32: ...HY70OM 8 99 32 ...

Page 34: ...HY70OM 8 99 34 ...

Page 36: ...HY70OM 8 99 36 ...

Page 38: ...HY70OM 8 99 38 ...

Page 40: ...HY70OM 8 99 40 ...