HY70OM-8/99

18

8.4CHARGING A BATTERY

1. Remove the battery from the tractor before

charging.

2. Be sure charger is Off.

3. Connect charger leads to battery. Connect the

positive (+) connector from the charger to the

positive battery terminal. Connect the negative ()

connector of the charger to the negative battery

terminal.

To avoid possible injury, stand away from

battery when charger is turned on. A

damaged battery or a battery with an

internal short could explode.

4. Charge the battery using one of the methods shown

below. Follow the manufacturers instructions on the

charger.

5. If when charging the battery, violent gassing or

spewing of electrolyte occurs, or the battery case

feels hot (125 F- 52 C), reduce or temporarily halt

charging to avoid damaging the battery.

6. Always turn charger to Off before removing a the

battery.

MAINTENANCE:

Slow Charge

Fast Charge

10 hours @ 5 amps

2-1/2 hours @ 20 amps

5 hours @ 10 amps

1-1/2 hours @ 30 amps

1 hour @ 45 amps

8.6FUEL FILTER

Before servicing the fuel filter, thoroughly clean

outside of filter housing and fuel hoses, dirt must not be

allowed to enter into fuel or fuel system. Refer to the

engine manual for specific instructions.

8.7ENGINE

Refer to Engine Manual for manufacturers

maintenance recommendations. Change oil and oil filter

after the first 25 hours of operation and every 150 hours

thereafter.

Engine replacement parts should be ordered

through your local Briggs & Stratton dealer.

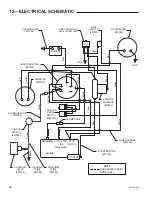

8.8ELECTRICAL SYSTEM

Make certain all terminals and connections are

kept clean and properly secured.

1.

Check switches regularly to be sure they are kept

clean and operating correctly. See 7.2, 7.3 and

7.4 in the Adjustments section.

2.

Keep wire harness and all individual wires away

from moving parts to prevent abrasive wear or

potential short circuits.

3.

Exercise extreme care when working with the

electrical system.

NOTE

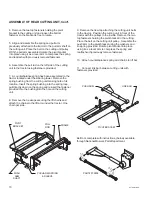

8.5BED KNIFE REPLACEMENT

When the bed knife becomes damaged or too worn to keep

sharp, it must be replaced. Design improvements have made

bed knife replacement easier with bolt-on construction. Follow

the procedure below.

1. The backbar (1), bed knife (2) and fasteners have been

assembled at the factory under tension. To ease

replacement and prevent misalignment of components, the

leading edge of the backbar must be tack welded two or

three places before the old fasteners are removed.

2. Remove shoulder nuts (3) and flat head screws (4). If

shoulder nuts are badly rusted or corroded, they may have

to be cut off and screws driven out to be removed.

3. Clean the bottom surface of the backbar for maximum

metal contact with the new bed bar.

4. Fasten the new bed knife to the bottom of the backbar in

the position shown (bent edge up). Shoulder of shoulder

nuts must be seated firmly in the backbar and screws must

be flush with the bottom of the bed knife.

5. Torque shoulder nuts 35 to 40 ft/lbs.

Tack weld this edge

Summary of Contents for HYDRO 70" TRIPLEX

Page 28: ...HY70OM 8 99 28 ...

Page 30: ...HY70OM 8 99 30 ...

Page 32: ...HY70OM 8 99 32 ...

Page 34: ...HY70OM 8 99 34 ...

Page 36: ...HY70OM 8 99 36 ...

Page 38: ...HY70OM 8 99 38 ...

Page 40: ...HY70OM 8 99 40 ...