16

|

ni.com

|

NI 9503 C Series Stepper Drive Modules and SoftMotion Module

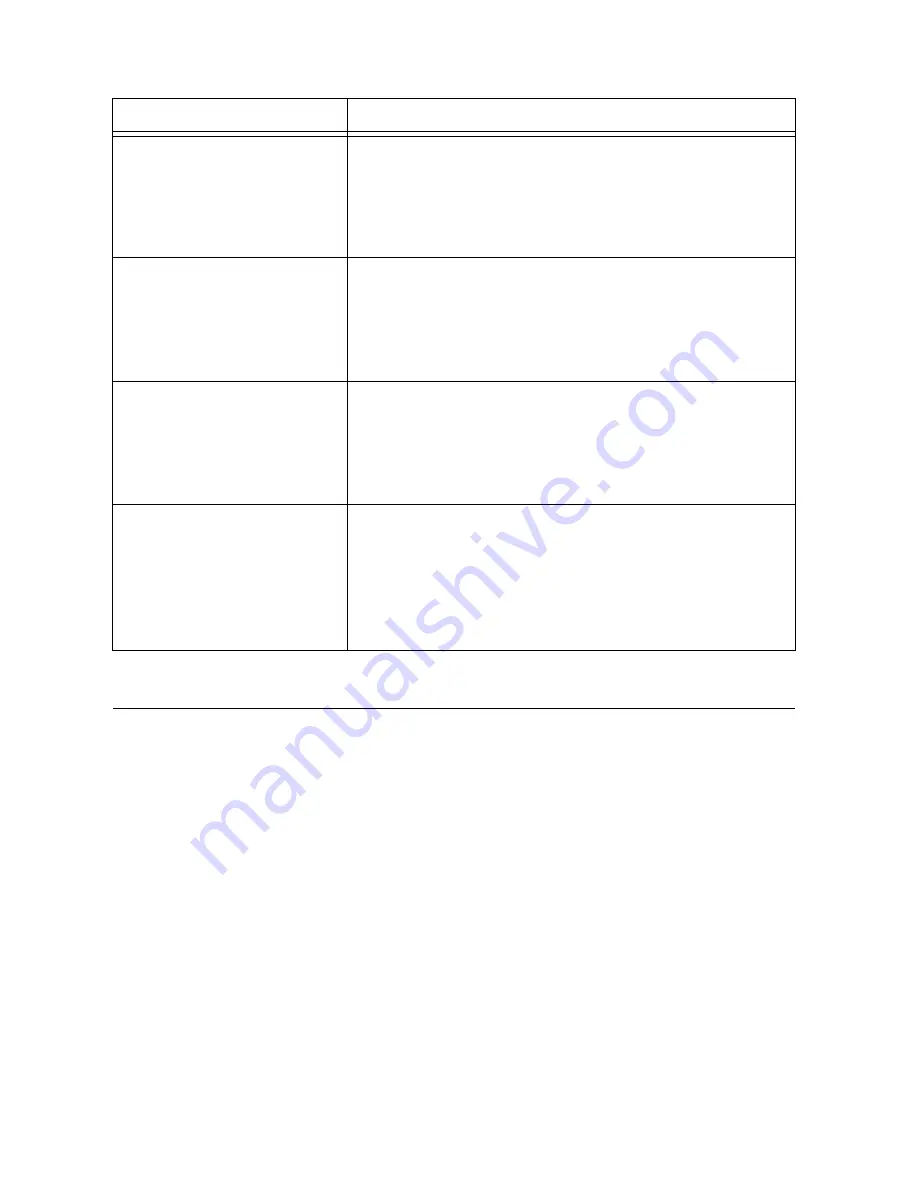

Table 10.

Stepper Drive (with Encoder) Additional FPGA Loop Descriptions

Tips and Trou

b

leshooting

Drive Fault on Ena

b

le

If you receive fault 7180 when you enable the NI 9503, verify that the

Rated Phase Current

setting is set to the appropriate value for your motor in Amps/Phase. Refer to Table 2 for

information about how to determine this value.

Complete the following steps to correct the setting:

1.

Set the

Rated Phase Current

in the

Axis Configuration

dialog box and click

OK

when

you are done.

2.

Right-click the axis in the

Project Explorer

window and select

Deploy

from the shortcut

menu to deploy the updated setting.

Table 11.

FPGA Loop Name

Description

Position Loop

When used with encoder feedback, the Position Loop

calculates interpolated positions, filters the encoder velocity

using the user-specified filter settings, and returns the

feedback position and filtered velocity feedback

information to the SoftMotion Engine.

Encoder Loop

The encoder loop uses the signals from the NI 9411 module

to generate position and velocity feedback. Position Capture

operations are included in the encoder loop to perform the

Index capture operation for use with the SoftMotion Find

Index routine.

DIO Config (Port A)

The DIO Config Port A loop manages the DIO contained in

DIO Port A. This includes the Forward Limit, Reverse

Limit, Home Switch, and Digital Inputs 0 though 3 from the

NI 9423 C Series module, and Digital Outputs 0 through 3

that are sent to the NI 9472 C Series module.

DIO Config (Port B)

The DIO Config Port B loop manages the DIO contained in

DIO Port B. This includes the Position Capture Input and

Position Compare Output from the NI 9401 C Series

module, Digital Inputs 4 though 7 from the NI 9423 C

Series module, and Digital Outputs 4 through 7 that are sent

to the NI 9472 C Series module.