22

|

ni.com

|

NI 9218 Calibration Procedure

c.

Call and configure the DAQmx Setup 9218 Calibration function according to

Table 30.

d.

Configure DMM1 for a voltage measurement in the 10 V range.

e.

Enable autozero on DMM1.

f.

Configure DMM2 for a voltage measurement in the 100 mV range.

g.

Enable autozero on DMM2.

h.

Call the DAQmx Get 9218 Calibration Adjustment Points function to obtain an array

of recommended calibration points for the NI 9218. The adjustment points can be

achieved by observing the following conditions.

•

The max test point is achieved by following the diagram in Figure 6.

•

The mid test point is achieved by following the diagram in Figure 7.

•

The min test point is achieved by following the diagram in Figure 8.

i.

Acquire voltage measurements with both DMMs. Perform the following calculation

using the two DMM measurements.

Note

Perform the DMM measurements simultaneously in order to reduce error

from drift in the resistors.

j.

Call and configure the DAQmx Adjust 9218 Calibration function according to

Table 31.

Note

The NI 9218 acquisition starts each time the adjustment function is called.

k.

Repeat steps d through k for every value in the array.

l.

Close and commit the calibration session.

4.

Repeat steps 3c through 3l for each channel on the NI 9218.

5.

Disconnect the DMMs and the resistors from the NI 9218.

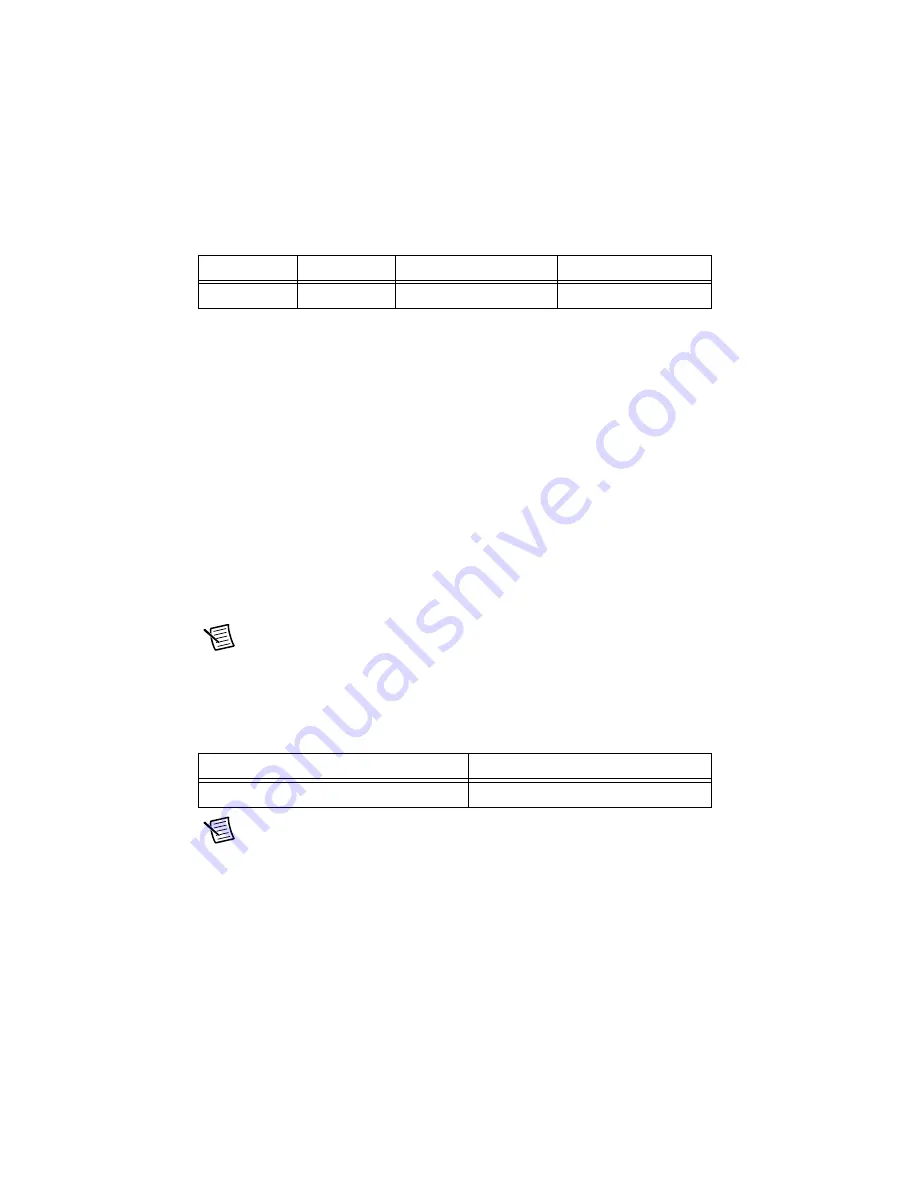

Table 30.

Setup Configuration for Bridge Accuracy Adjustment

Min (V/V)

Max (V/V)

Physical Channels

Measurement Type

-0.022

0.022

cDAQMod8/ai

x

Bridge

Table 31.

Adjustment Configuration

Physical Channel

Reference Value

cDAQMod8/AI

x

Ratio

ref

Ratio

ref

V

DMM

2

V

DMM

1

------------------

=