6

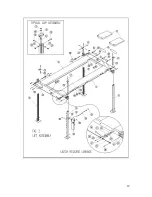

COLUMN & CROSSRAIL INSTALLATION

Lay down rear columns. Position the

crossrail at the top of the two columns. (both cross rails are the same ) Install the

crossrail in the column by sliding the plastic guide blocks into the column

channel. The safety latch must be positioned with bevel side to the leg top, and

safety latch facing towards the outside of the lift when you stand the columns

back up. Manually open the safety latch devise on each side of the crossrail and

slide the crossrail down until it rests on the safety lock position closest to the

floor. Repeat the procedure for the remaining columns and crossrail. Stand the

assembled columns up in the positions indicated on the floor plan.

Track Installation

Start with the track with the cylinder. This track will be located with the hose

connection facing out toward the leg with power unit bracket attached.

NOTE

The

power unit can be located in two locations shown. With an assistant, pick up and

place one end of the main side track on the crossrail, and then pick up and place

the other end on the opposite crossrail (if you have three assistants, place both

ends at the same time). Use a large screwdriver or aligning punch to align the

mounting holes in the cross rails with the mounting holes in the track.

Do not

leave the tracks unbolted – install the mounting bolts immediately!

Install

1/2” x 4” mounting bolts and 1/2” washers

thru the ramp brackets and wheel

stops. Make sure the bolt head is on the flat side of the bracket. Install the two

ramp brackets and two wheel stop with bolts and washers as you secure the

main side track to the cross rail. Secure the bolts with 1/2” washers and nuts

placed

hand tight

. Now, install the offside track and again secure with ramp

brackets, wheel stops with

1/2” x 4” bolts and nuts

. After both tracks are

installed, tighten all bolts 1/2” x 4” bolts - torque - 45 ft-lbs.

Summary of Contents for NSS8XLT

Page 1: ...NSS8XLT NSS8XLT Installation Installation Manual Manual...

Page 11: ...11...

Page 12: ...12...

Page 13: ...13...